Formwork combination reinforcing and supporting structure used in short-leg shear wall construction and construction method thereof

A technology of supporting structure and construction method, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, building structure, etc. It is not good, the upper formwork is not fixed firmly, etc., to achieve the effect of shortening the construction period, excellent stability, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

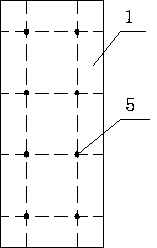

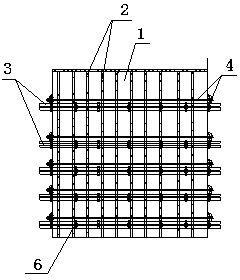

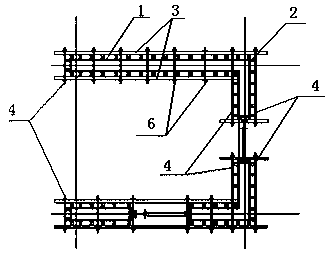

Image

Examples

Embodiment Construction

[0028] The invention aims at the formwork installation of the short-leg shear wall, and uses the support of the formwork itself in combination with the wall hoop bolts and pre-embedded bolts to improve the stability of the formwork support system of the short-limb shear wall and ensure that the formwork is in a horizontal position, structurally Dimensionally accurate. Without adding additional investment and saving materials, the construction period is shortened, the forming quality of the concrete shear wall is improved, and its comprehensive technical performance exceeds the effect of the traditional support system. The structure of the present invention is very stable, not only meets the effect of formwork support and reinforcement, but also can be reused to achieve the effect of reducing the cost.

[0029] The construction method of the template combination reinforcement support structure of the present invention, the steps are as follows:

[0030] 1) Formwork productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com