Steel for axle housing and preparation method thereof

An axle housing and axle technology, applied in the field of automobile brake pads, can solve problems such as affecting product quality and service life, easy cracking, etc., and achieve excellent stamping and welding performance, small stamping springback, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

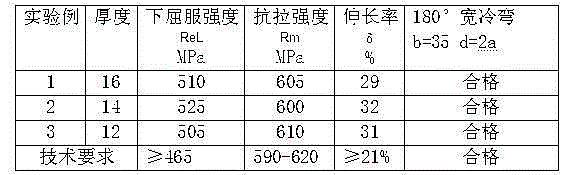

Embodiment 1

[0021] Production of steel plates for axle housings with a thickness of 16 mm.

[0022] A steel for axle housing, its chemical composition and weight percentage are: C: 0.096%, Si: 0.89%, Mn: 0.75%, P: 0.015%, S: 0.003%, Al: 0.029%, Ti: 0.046 %, Nb: 0.059%, Mo: 0.18%, Ce: 0.52%, W: 4.96%, Cr: 1.72%, and the rest are Fe and unavoidable impurities.

[0023] A method for preparing steel for an axle housing, characterized in that it comprises the following steps:

[0024] 1) According to the chemical composition and weight percentage of the above-mentioned steel for the axle housing, the ingredients are prepared and smelted, and the temperature of the molten steel is 1685°C to 1690°C;

[0025] 2) Carry out vacuum treatment: the treatment time is 16 minutes, and the vacuum degree is kept at 725Pa;

[0026] 3) Carry out continuous casting into blanks, the molten steel temperature is in the range of 1600°C to 1650°C, the casting speed is 1.4 m / min, and the casting frequency is 120 ...

Embodiment 2

[0032] Production of steel plates for axle housings with a thickness of 14mm

[0033] A steel for axle housings, the chemical composition and weight percentage are: C: 0.12%, Si: 0.85%, Mn: 1.19%, P: 0.017%, S: 0.005%, Al: 0.07%, Ti: 0.06% , Nb: 0.05%, Mo: 0.12%, Ce: 0.62%, W: 4.8%, Cr: 1.68%, and the rest are Fe and unavoidable impurities.

[0034] A method for preparing the steel for the axle housing of the claim, comprising the following steps:

[0035] 1) According to the chemical composition and weight percentage of the above-mentioned steel for the axle housing, the ingredients are prepared and smelted, and the temperature of the molten steel is 1660°C to 1685°C;

[0036] 2) Carry out vacuum treatment: the treatment time is 15 minutes, and the vacuum degree is kept at 700Pa;

[0037] 3) Carry out continuous casting into blanks, the molten steel temperature is in the range of 1550°C to 1650°C, the casting speed is 1.3 m / min, and the casting frequency is 105 times / min; ...

Embodiment 3

[0043] Production of 12mm thick steel plates for axle housings

[0044] A steel for axle housings, the chemical composition and weight percentage are: C: 0.08%, Si: 1.0%, Mn: 0.62%, P: 0.013%, S: 0.012%, Al: 0.055%, Ti: 0.05% , Nb: 0.062%, Mo: 2.1%, Ce: 0.48%, W: 5.2%, Cr: 0.32%, and the rest are Fe and unavoidable impurities.

[0045] A method for preparing steel for the axle housing, comprising the following steps:

[0046] 1) According to the chemical composition and weight percentage of the above-mentioned steel for the axle housing, the ingredients are prepared and smelted, and the temperature of the molten steel is 1650°C to 1660°C;

[0047] 2) Carry out vacuum treatment: the treatment time is 13 minutes, and the vacuum degree is kept at 680Pa;

[0048] 3) Carry out continuous casting into blanks, the temperature of molten steel is in the range of 1550°C to 1650°C, the casting speed is 1.2-1.4 m / min, and the casting frequency is 90-120 times / min;

[0049] 4) Heating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com