Low-cost cold-rolled steel plate production method

A technology of cold-rolled steel sheet and production method, which is applied in the field of low-cost cold-rolled steel sheet production, can solve problems such as rising production costs, and achieve the effects of lower production costs, better material strength, and better stamping and forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is further described:

[0024] A method for producing low-cost cold-rolled steel sheets, comprising the following steps performed in sequence:

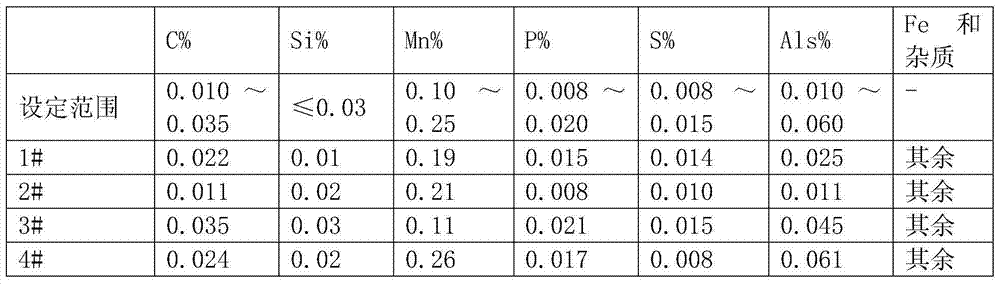

[0025] A. Control the composition of molten steel, by weight percentage, C: 0.010% ~ 0.035%, Si: ≤0.03%, Mn: 0.10% ~ 0.25%, P: 0.008% ~ 0.020%, S: 0.008% ~ 0.015%, Als : 0.010% ~ 0.060%, the rest is Fe and unavoidable impurities, and then the molten steel is cast into billets;

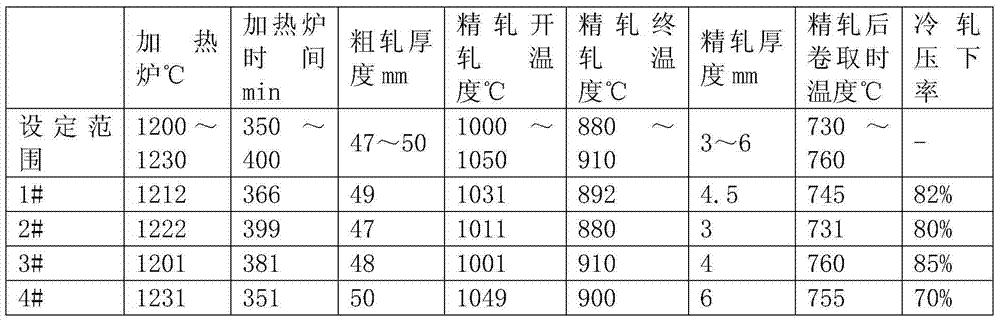

[0026] B. The billet enters the heating furnace, heated to 1200-1230°C, and the time in the furnace is 350-400min; the heated billet is rough-rolled, and the thickness of the rough-rolled slab obtained is 47-50mm;

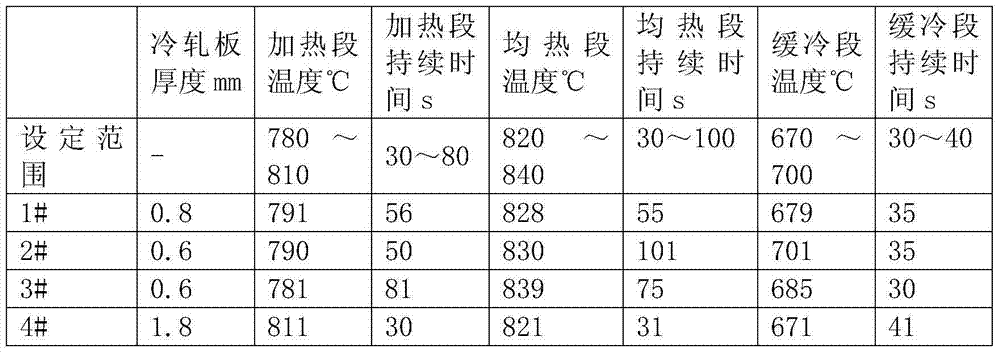

[0027] C. Carry out finishing rolling to the rough rolling slab, the finishing rolling start temperature is 1000~1050 ℃, the finishing rolling finishing temperature is 880~910 ℃, obtain the finishing rolling slab, the finishing rolling slab thickness is 3~6mm; The finish-rolled sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com