Duplex stainless steel plate having excellent press moldability

A duplex stainless steel, stamping formability technology, applied in the furnace type, furnace, heat treatment furnace, etc., can solve problems such as unclear, and achieve the effect of saving Ni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Hereinafter, examples of the present invention will be described.

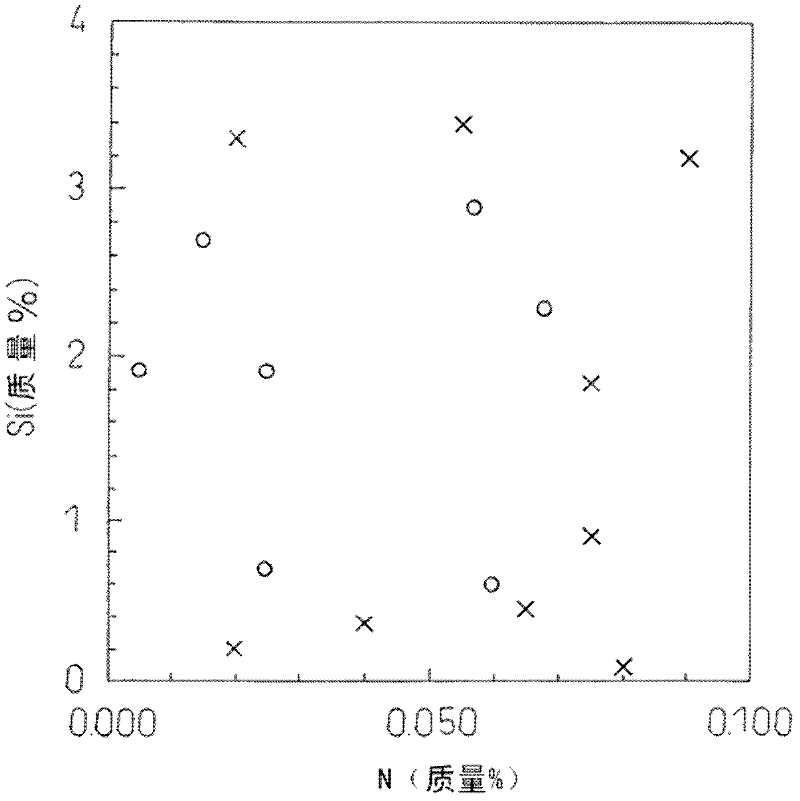

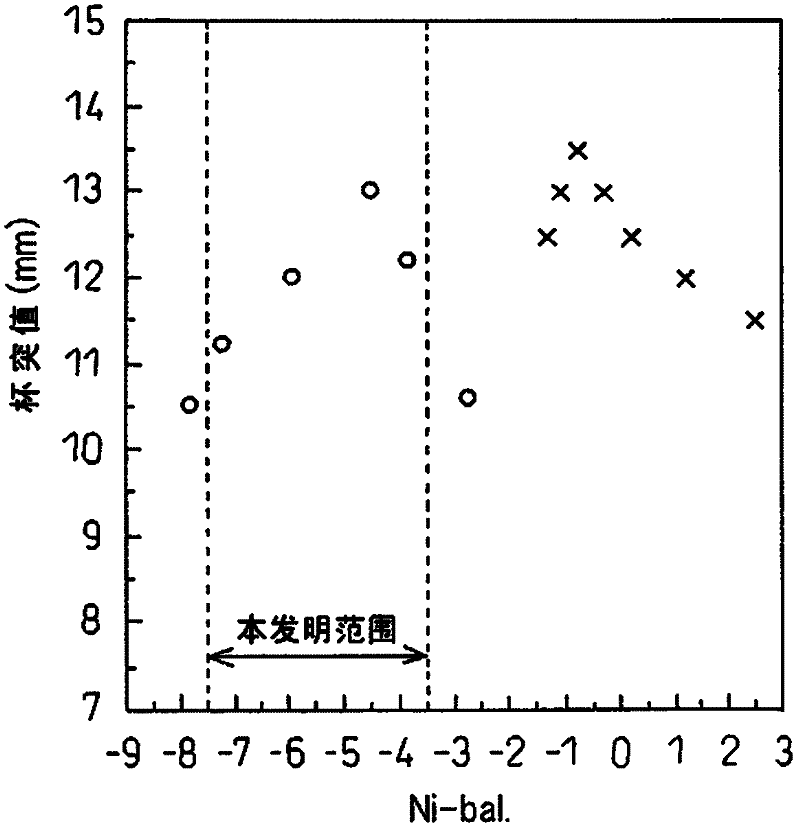

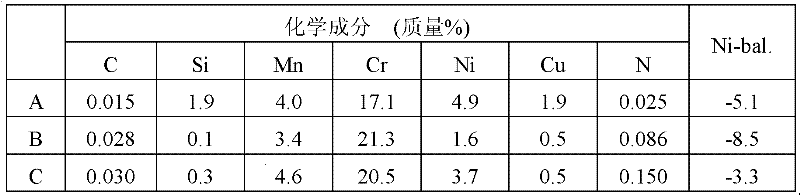

[0095] Duplex stainless steel having the composition shown in Table 3 was melted and hot-rolled to produce a hot-rolled sheet having a sheet thickness of 4.0 to 5.0 mm. Steel No. 1 to Steel No. 22 have the components and Ni-bal. specified in the present invention. Steel Nos. 23 and 24 have the composition specified in the present invention, but Ni-bal. deviates from the present invention. Steel Nos. 25 to 27 have Ni-bal. specified in the present invention, but the composition range deviates from the present invention. After these hot-rolled sheets were annealed and pickled, they were cold-rolled to a thickness of 0.7 mm, and final annealed at 1050°C.

[0096] table 3

[0097]

[0098] Ni-bal.=30(C+N)+0.5Mn+0.3Cu+Ni-1.1(Cr+1.5Si)+8.2

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com