Transparent pressure-sensitive adhesive sheet and flat panel display

A flat panel display, adhesive sheet technology, applied in the direction of adhesive type, polyether adhesive, film/flake adhesive, etc., can solve the problems of large light reflection loss, inability to achieve good visibility, etc. Achieve improved peel force, excellent visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

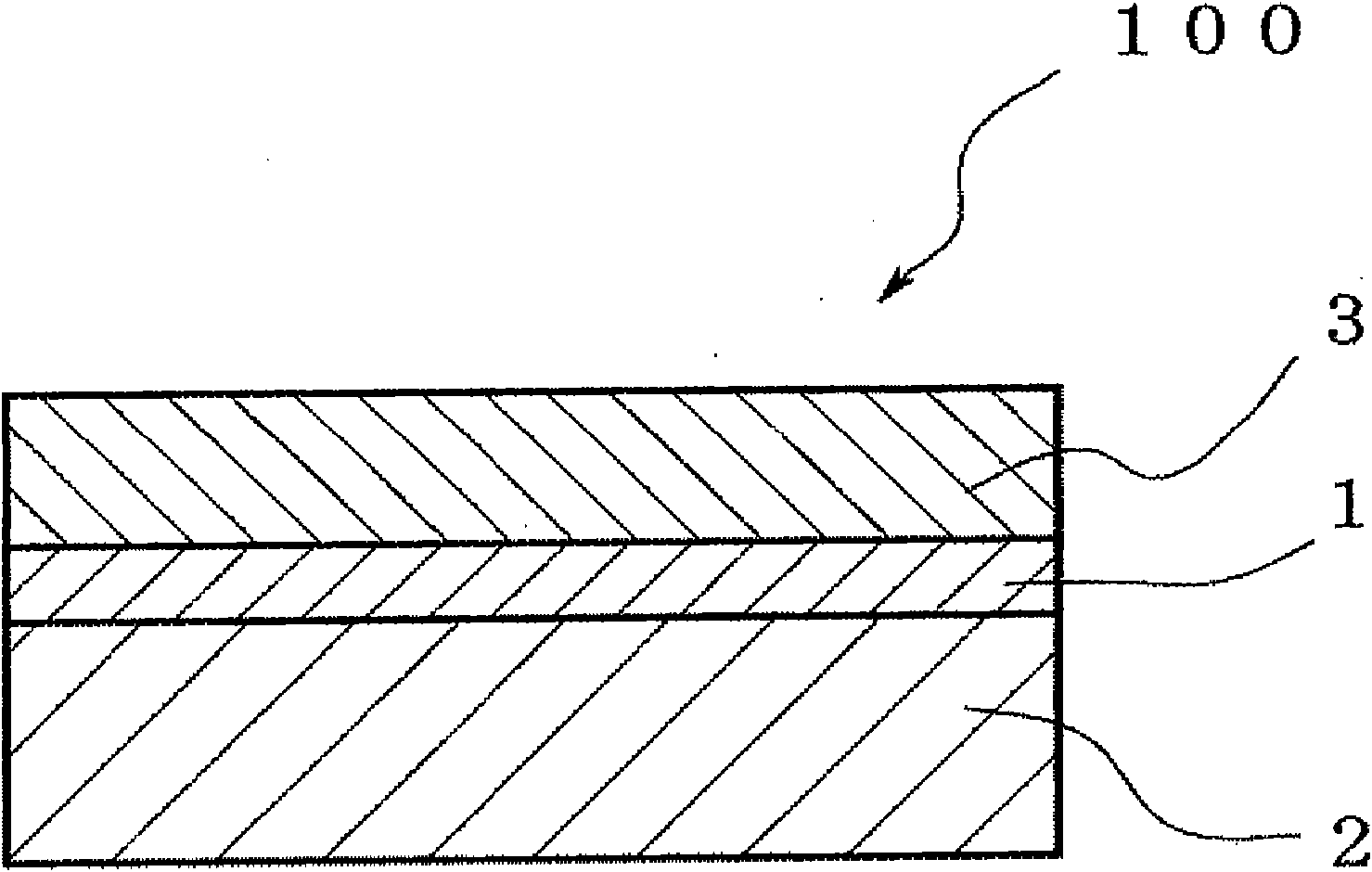

[0207] The polyoxyalkylene polymer (number-average molecular weight: about 20,000) used in component A, the hydrosilyl compound used in component B provided a functional group ratio of 0.75 (the amount of the hydrosilyl group relative to that used in The amount of the alkenyl group of the polyoxyalkylene polymer of component A) and the composition containing a hydrosilylation catalyst for component C (manufactured by KANEKA Corporation, 0.75 mol relative to 1 mol of alkenyl group in component A) into a stirrer (Mini Dappo manufactured by SEATECCOPORATION) with a vacuum device, and the mixture was stirred in vacuum (100 Pa) for 1 hour to defoam. Then, the vacuum defoaming composition was applied (cast) at room temperature on a release-treated base separator (support) made of a polyester film (thickness: 100 μm) with a roll coater, to a composition thickness of 200 μm. The composition was cured by heating at 130° C. for 10 minutes in an oven. A release-treated cover separator ...

Embodiment 2

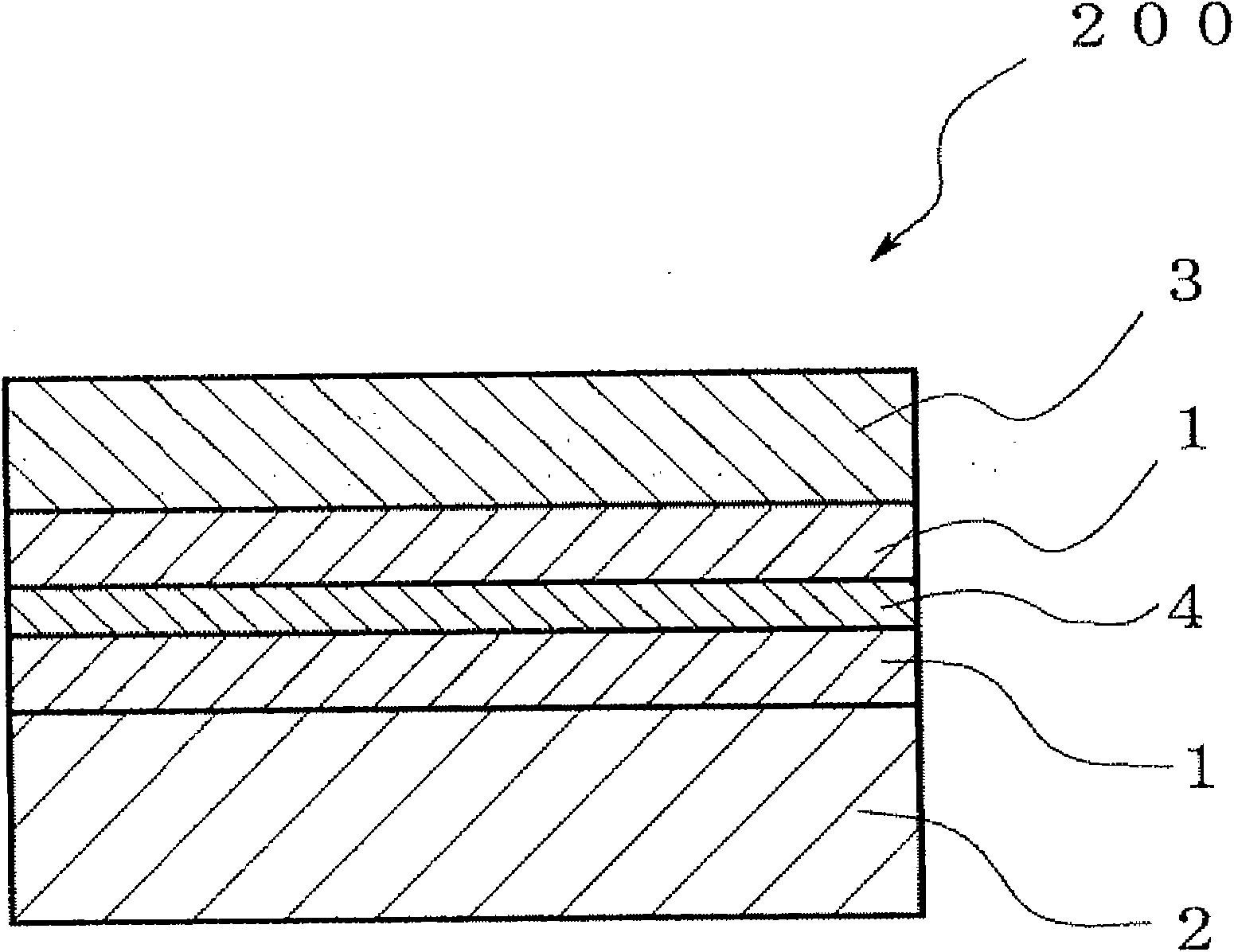

[0221] A transparent adhesive sheet was prepared in the same manner as in Example 1 except that the coating thickness of the composition was changed to 100 μm. Using the obtained transparent adhesive sheet, a potential difference absorption test was performed. The results are shown in Table 2.

Embodiment 3

[0230] A transparent adhesive sheet was prepared in the same manner as in Example 1 except that the coating thickness of the composition was changed to 250 μm. Using the obtained transparent adhesive sheet, the resistance of the film having the ITO layer was measured. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com