High-performance conductive silver paste and preparation method thereof

A conductive silver glue, high-performance technology, used in conductive adhesives, circuits, adhesives, etc., can solve the problems of scarcity of products required for the use of high-power LEDs, and achieve low curing temperature, high thermal conductivity, and even size dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1. A high-performance conductive silver glue, which is made of the following raw materials in weight percentage:

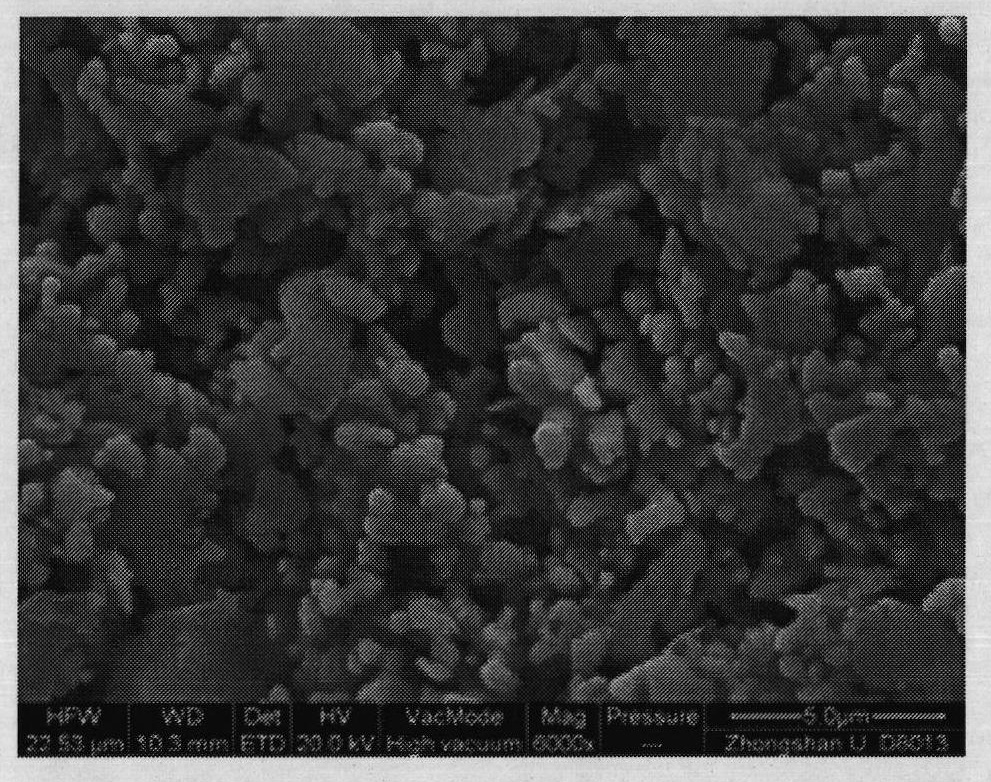

[0039] Micron-sized metallic silver powder 79.05%;

[0040] Epoxy resin 12%;

[0041] Curing agent 1.4%;

[0042] Solvent 6%;

[0043] Accelerator 0.5%;

[0044] Toughener 0.05%;

[0045]Additive 1%.

[0046] Prepared by conventional methods.

Embodiment 2

[0047] Example 2. A high-performance conductive silver glue, which is made of the following raw materials in weight percentage:

[0048] Micron-sized metallic silver powder 74.2%;

[0049] Epoxy resin 10%;

[0050] Curing agent 3.5%;

[0051] Solvent 9%;

[0052] Accelerator 1.2%;

[0053] Toughener 0.1%;

[0054] Additives 2%.

[0055] Its preparation method steps are as follows:

[0056] (1) Take the toughening agent and epoxy resin in proportion, heat and stir at 140°C for 2 hours to mix evenly, and obtain the prepolymer for later use;

[0057] (2) Take the prepolymer, add curing agent, solvent, accelerator and additives in proportion, fully stir evenly, and obtain the matrix for subsequent use;

[0058] (3) Take micron-sized metal silver powder in proportion and add it to the matrix and stir it thoroughly, then put it into a three-roller machine and mix evenly to obtain the product.

Embodiment 3

[0059] Example 3. A high-performance conductive silver glue, which is made of the following raw materials in weight percentage:

[0060] Micron-sized metallic silver powder 65%;

[0061] Epoxy resin 20%;

[0062] Curing agent 3%;

[0063] Solvent 8.73%;

[0064] Accelerator 1.2%;

[0065] Toughener 0.07%;

[0066] Additives 2%.

[0067] Its preparation method steps are as follows:

[0068] (1) Take the toughening agent and epoxy resin in proportion, heat and stir at 160°C for 5 hours to mix evenly, and obtain the prepolymer for later use;

[0069] (2) Take the prepolymer, add curing agent, solvent, accelerator and additives in proportion, fully stir evenly, and obtain the matrix for subsequent use;

[0070] (3) Take micron-sized metal silver powder in proportion and add it to the matrix and stir it thoroughly, then put it into a three-roller machine and mix evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com