Preparation method of polyurethane foam stabilizer

A polyurethane foam and stabilizer technology, applied in the field of preparation of polyurethane foam stabilizers, can solve the problems of reducing the safety of production operations, increasing reaction operation steps and production costs, environmental pollution, etc., achieving reduction of reaction operation steps and production costs, The effect of saving consumption and reducing pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

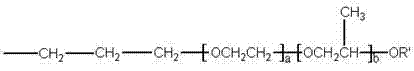

[0032] (1) Add 11.6g of allyl alcohol, 176g of ethylene oxide and 116g of propylene oxide into the reaction kettle, under the action of 0.4g of KOH, control the reaction temperature at 110°C and the reaction pressure of 0.4MPa, and react for 4 hours , when the system pressure is reduced to less than 0.15MPa, the temperature is lowered to stop the reaction, and the allyl-terminated copolyether is obtained after neutralization, filtration and extraction;

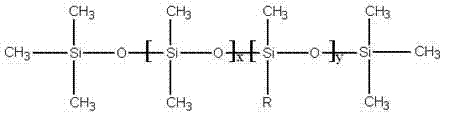

[0033] (2) Put 152g of octamethylcyclotetrasiloxane, 6.8g of hexamethyldisiloxane and 36g of high hydrogen-containing silicone oil with a hydrogen content of 1.6% in the presence of sulfonic acid type cation exchange resin at a temperature of 40 Under the condition of ℃, the low hydrogen-containing silicone oil with a hydrogen content of 0.4% is obtained;

[0034] (3) 78g of allyl-terminated copolyether obtained in step (1), 20.8g of low-hydrogen silicone oil obtained in step (2), 15ppm of chloroplatinic acid, and an ami...

Embodiment 2

[0037] (1) Add 8g of allyl alcohol, 191g of ethylene oxide and 114g of propylene oxide into the reaction kettle, under the action of 0.4g of KOH, control the reaction temperature of 120°C and the reaction pressure of 0.4MPa, and react for 5 hours. When the system pressure is reduced to less than 0.15MPa, the temperature is lowered to stop the reaction, and the allyl-terminated copolyether is obtained after neutralization, filtration and extraction;

[0038] (2) Put 100g of octamethylcyclotetrasiloxane, 8.8g of hexamethyldisiloxane and 22g of high hydrogen-containing silicone oil with a hydrogen content of 1.6% in the presence of sulfonic acid type cation exchange resin at a temperature of 40 Under the condition of ℃, the low hydrogen-containing silicone oil with a hydrogen content of 0.5% is obtained;

[0039] (3) 70 g of the allyl-terminated copolyether obtained in step (1), 30 g of low-hydrogen silicone oil obtained in step (2), 20 ppm of chloroplatinic acid, and an am...

Embodiment 3

[0042] (1) Add 5.8g of allyl alcohol, 66g of ethylene oxide and 46g of propylene oxide into the reaction kettle, under the action of 0.2g of KOH, control the reaction temperature at 110°C and the reaction pressure of 0.4MPa, and react for 4 hours , when the system pressure is reduced to less than 0.15MPa, the temperature is lowered to stop the reaction, and the allyl-terminated copolyether is obtained after neutralization, filtration and extraction;

[0043] (2) Put 550g of octamethylcyclotetrasiloxane, 20g of hexamethyldisiloxane and 158g of high hydrogen-containing silicone oil with a hydrogen content of 1.8% in the presence of sulfonic acid type cation exchange resin at a temperature of 50°C Under the condition of reaction, low hydrogen-containing silicone oil with a hydrogen content of 0.3% is obtained;

[0044] (3) 72g of the allyl-terminated copolyether obtained in step (1), 28g of low-hydrogen silicone oil obtained in step (2), 20ppm of chloroplatinic acid, and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com