Flame retardant fiber and preparation method thereof

A flame-retardant fiber and cellulose technology, which is applied in the manufacture of fire-resistant and flame-retardant filaments, the preparation of spinning solutions, and cellulose/protein conjugated artificial filaments, can solve the problems of reduced flame retardancy, poor flame-retardant durability, and fiber It is difficult to evenly distribute and other problems, and achieve the effect of good flame retardancy, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

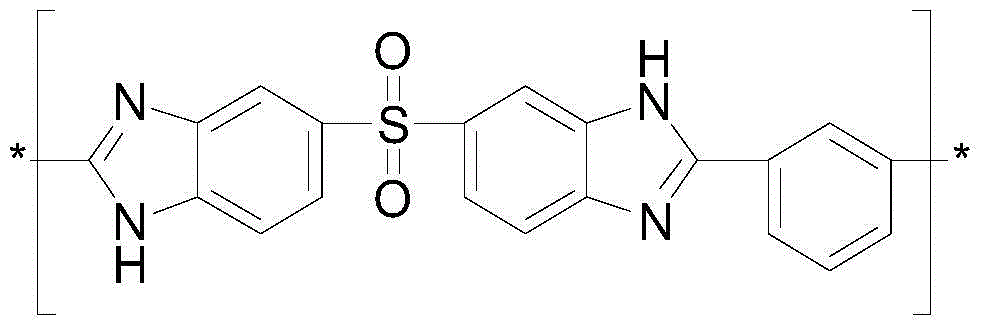

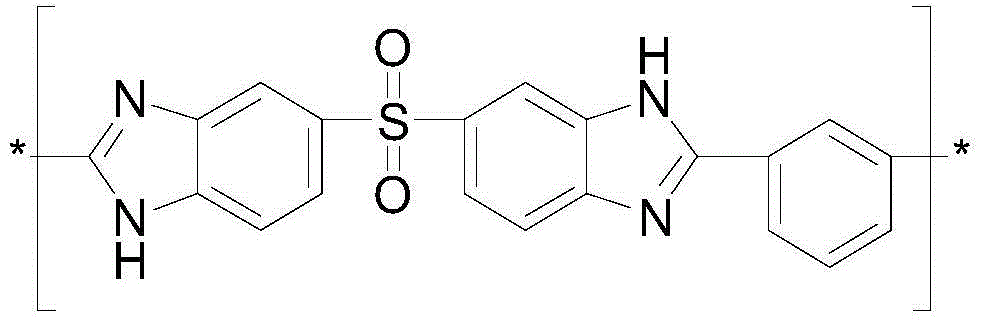

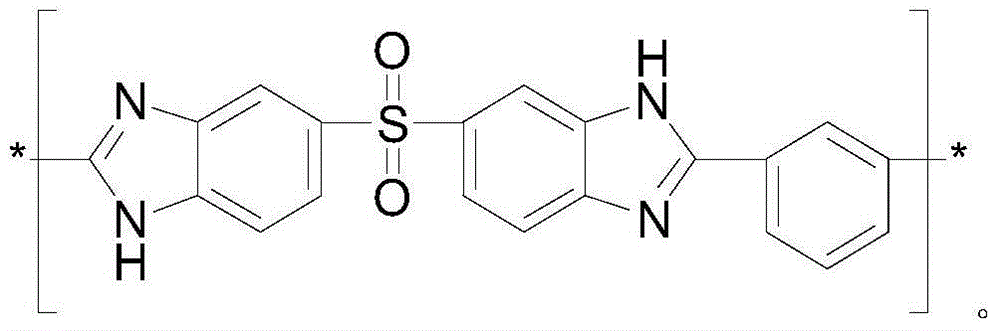

Image

Examples

Embodiment 1

[0026] The cellulose with a degree of polymerization of 200 and the polym-phenylene isophthalamide with an inherent viscosity of 1.5dL / g are mixed according to the ratio of 50:50 in mass ratio, and mixed in 4-methylmorpholine-N Stir in a 50% aqueous solution of the oxide, swell at 80°C, and vacuum dehydrate until completely dissolved to obtain a spinning solution with a total polymer solid content of 5% and an apparent viscosity of 85 Pa·s. Degassing, conveying, filtering at 80°C, cooling down to 70°C, the apparent viscosity of the spinning solution is 650Pa·s. Apply a pressure of 0.4MPa, after passing through a 20mm air section and a coagulation bath (water, 25°C), the drawing ratio in the coagulation bath is 2 times, enter the drawing bath of 60°C water, draw 2 times, and then enter boiling water Drawing bath, drafting 1.2 times, then washing, drying, heat setting, to obtain fibers.

[0027] The monofilament fineness of the fiber was 2.8 dtex, the breaking strength was 3.0 ...

Embodiment 2

[0029] The cellulose with a degree of polymerization of 800 and the polym-phenylene isophthalamide with an inherent viscosity of 2.5dL / g are mixed according to a mass ratio of 20:80, in 1-butyl-3-methanol Stir in imidazolium chloride salt solvent and dissolve at 85°C to obtain a spinning solution with a total polymer solid content of 15% and an apparent viscosity of 530 Pa·s. Degassing, transporting and filtering at 85°C, cooling down to 80°C, the apparent viscosity of the spinning solution is 1030Pa·s. Apply a pressure of 0.6MPa, after passing through a 20mm air section and a coagulation bath (water, 20°C), the drawing ratio in the coagulation bath is 1.5 times, enter the drawing bath of 55°C water, draw 3 times, and then enter boiling water Drawing bath, drafting 1.5 times, then washing, drying, heat setting, to obtain fibers.

[0030] The monofilament fineness of the fiber was 2.4 dtex, the breaking strength was 3.2 cN / dtex, and the domain size of the formed cellulose was ...

Embodiment 3

[0032]Cellulose with a degree of polymerization of 1600 and polym-phenylene isophthalamide with an inherent viscosity of 2.0dL / g are mixed in a mass ratio of 40:60 in 1-butyl-3-methanol Stir in imidazolium bromide salt and dissolve at 70°C to obtain a spinning solution with a total polymer solid content of 10% and an apparent viscosity of 780 Pa·s. Degassing, conveying, filtering at 70°C, cooling down to 50°C, the apparent viscosity of the spinning solution is 1300Pa·s. Apply a pressure of 0.5MPa, after passing through a 20mm air section and a coagulation bath (water, 15°C), the drawing ratio in the coagulation bath is 2.5 times, enter the drawing bath of 60°C water, draw 1.6 times, and then enter boiling water In a drawing bath, the drawing ratio is 2 times, then washed with water, dried, and heat-set to obtain fibers.

[0033] The monofilament fineness of this fiber was 2.9 dtex, the breaking strength was 3.8 cN / dtex, and the domain size of the formed cellulose was 25 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com