Graphene/layered double hydroxide composite flame retardant and preparation method of polystyrene nanometer flame-retardant composite material

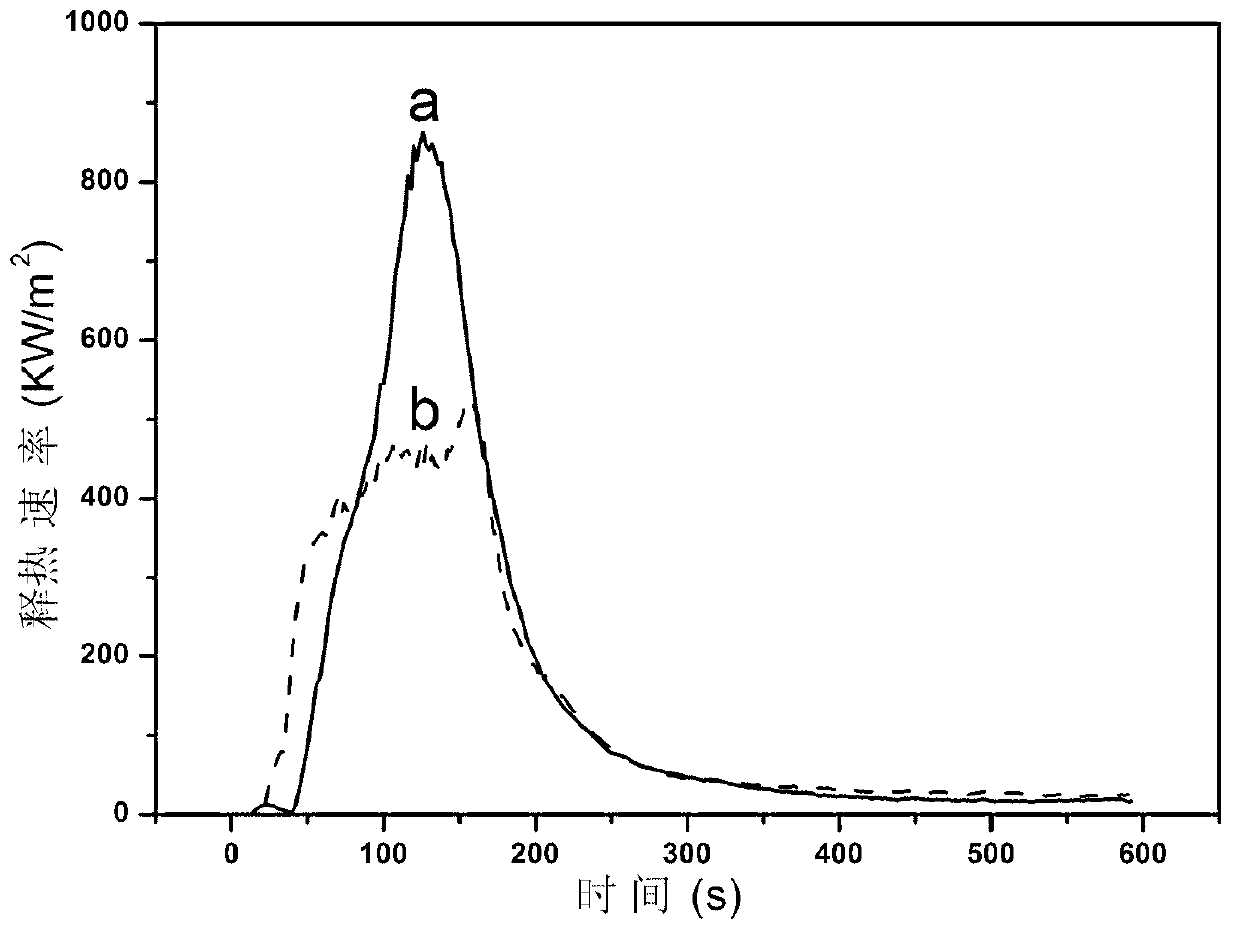

A polystyrene nano-hydroxide technology, which is applied in the preparation and application of inorganic composite flame retardants, can solve the problems of agglomeration, low output, unfavorable flame retardant efficiency, etc., and achieve small addition, high flame retardant efficiency, The effect of reducing secondary harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

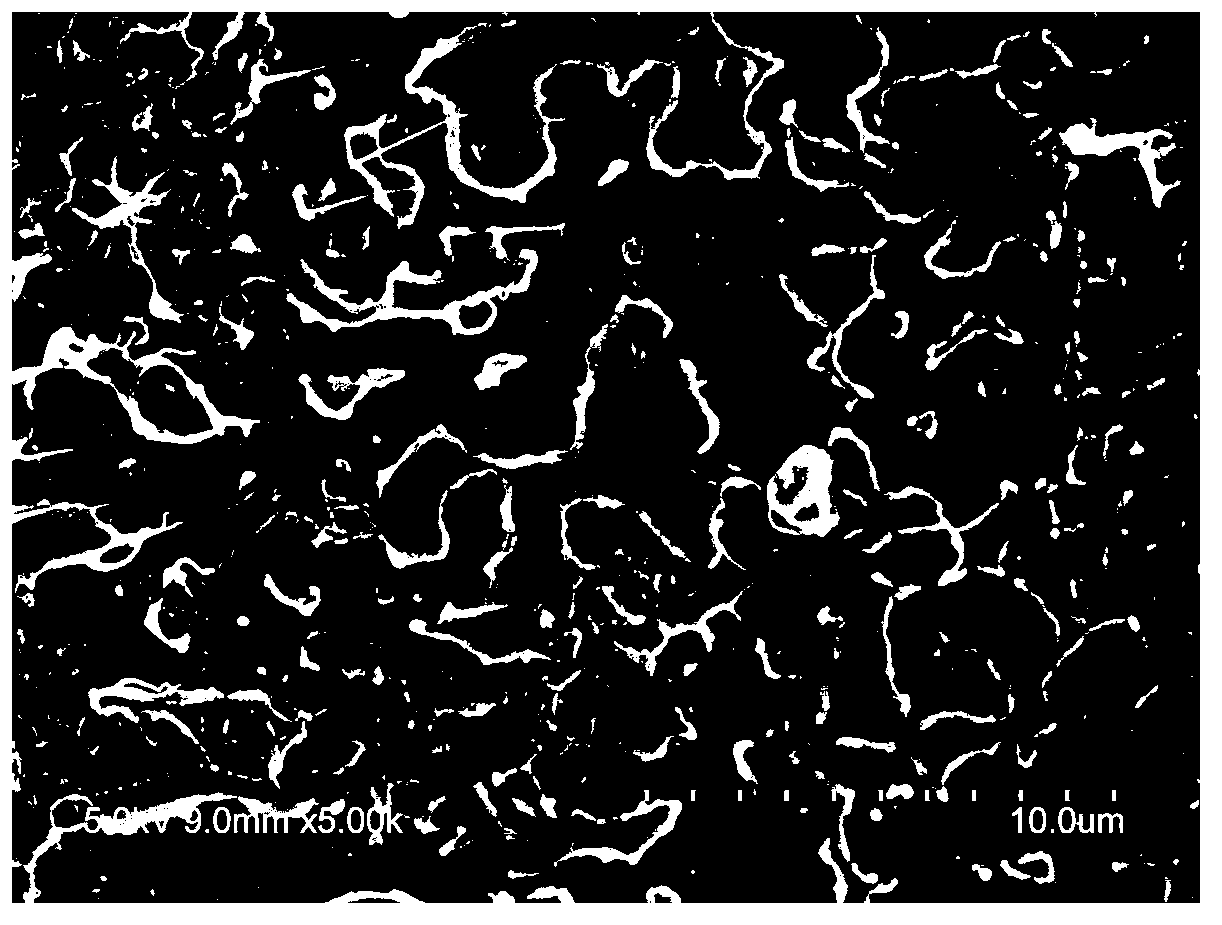

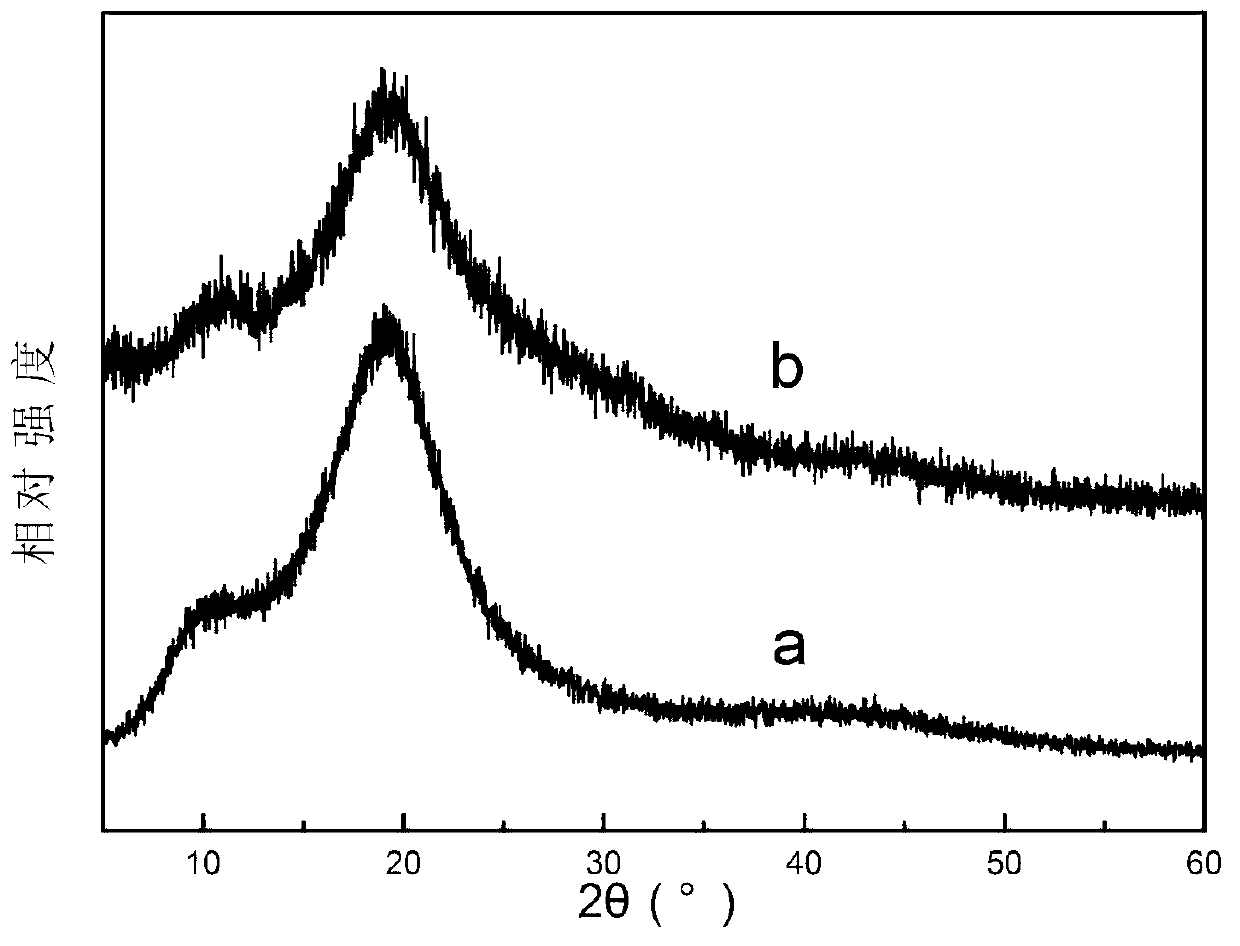

[0025]A preparation method of graphene / layered double hydroxide composite flame retardant and polystyrene nano flame retardant composite material, the steps are as follows:

[0026] (1) Prepare 1L 0.05g / L GO colloid (see Hummers WS, Offeman R E. Preparation of graphite oxide. J Am Chem Soc, 1958, 80: 1339 for the preparation method), and 0.2g CNTs (purchased from Chinese Academy of Sciences, Chengdu Organic Chemical Co., Ltd.) after acidification (see Han YQ, Shen MX, Lin XC, Ding B, Zhang LJ, Tong H, Zhang XG for the acidification method. Ternary phase interfacial polymerization of polypyrrole / MWCNT nanocomposites with core-shell structure. Synthetic Metals, 2012,162:753-758.) was added, and the mixture was ultrasonically dispersed in an ice bath for 2 hours to obtain a light black colloidal dispersion.

[0027] (2) Add 0.2 mol MgCl 2 (purchased from Nanjing Chemical Reagent Co., Ltd.) with 0.1molAlCl 3 (purchased from Nanjing Chemical Reagent Co., Ltd.) was successive...

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of graphene / layered double hydroxide composite flame retardant and polystyrene nano-flame retardant composite material, its place different from embodiment 1 is that the concentration of GO colloid becomes 0.1g / L, the quality of CNTs becomes 1g, ultrasonic dispersion 2h becomes 6h; MgCl in step 2 2 to ZnCl 2 ; In step 3, the composite assembly is changed from 5 parts to 2 parts.

Embodiment 3

[0030] Embodiment 3. A preparation method of graphene / layered double hydroxide composite flame retardant and polystyrene nano flame retardant composite material, its difference from Example 1 is that the volume of GO colloid in step 1 is changed from 1L to 4L , the mass of CNTs changed to 4g, ultrasonic dispersion from 2h to 12h, and the composite assembly in step 3 changed from 5 parts to 1 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com