Novel composite UHPC projectile-resistant layer capable of resisting repeated attacks

A technology of multiple repetitions and bulletproof layers, applied in wellbore linings, tunnel linings, underground chambers, etc., can solve the problems of lack of strong guarantee of durability, functional single bulletproof layer, and single protective function, etc. Achieve improved accuracy and quality, reduced catastrophic hazards, excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Two different construction scheme technologies will be given below

[0036] 1. Quasi-synchronous cast-in-place technical solution

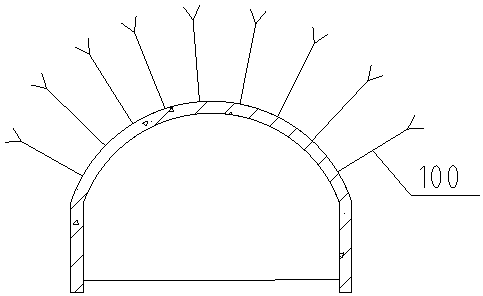

[0037] (a) Pouring UHPC air sandwich structure

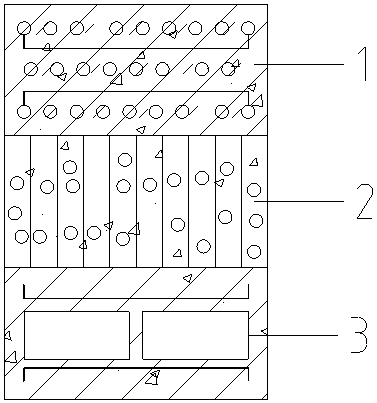

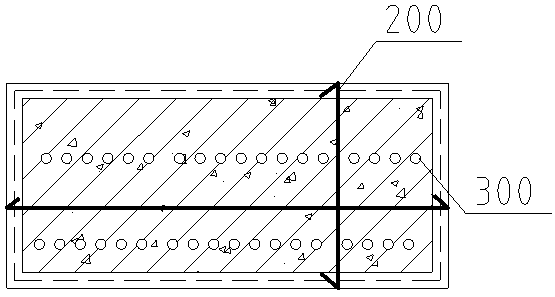

[0038] UHPC air interlayer structure can be divided into anti-explosion layer, air interlayer and collapse isolation layer from top to bottom. The height of the anti-blast layer is 400mm, using two-way double-layer reinforcement, using HRB335 steel bars with a diameter of 12mm, and the steel bar spacing is 100mm; The spacing between the steel bars is 100mm; HRB335 steel bars with a diameter of 10mm are used at the edge of the structure, and the spacing of the stirrups is 100mm, and the form of a four-leg hoop is used. First, the prefabricated mold is 600mm high, and the pouring of the bottom collapsed isolation layer is completed at one time. After seven days (steam curing) to reach the strength of 28 days, the next stage of pouring of the air interlayer is carried out. Place special woode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com