Manufacture process of imitation stainless steel metal drawbench film

A metal wire drawing film and manufacturing process technology, used in metal layered products, decorative arts, lamination auxiliary operations, etc., can solve the problems of poor corrosion resistance, poor corrosion resistance, low degree of scratch resistance, etc. performance and corrosion resistance, avoid environmental damage, improve the effect of fastness of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

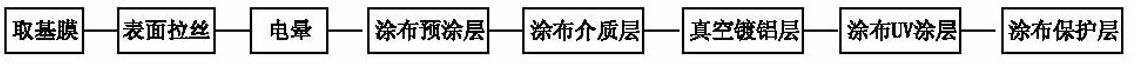

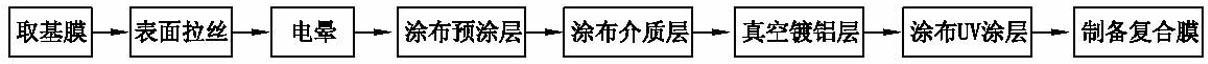

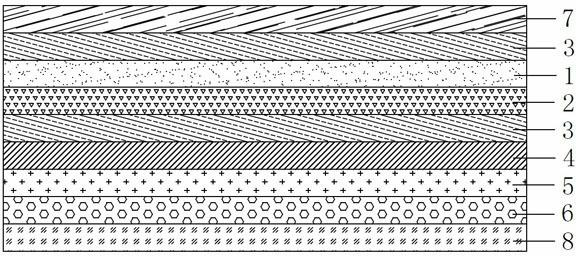

[0033] see Figure 1~3 As shown, the present invention relates to a manufacturing process of an imitation stainless steel wire drawing film, comprising the following process steps.

[0034] Firstly, choose a PET film as the base film 1 with a thickness of 15-250 μ, and you can choose a PET film with a corresponding thickness according to your needs; then, use emery attached to the surface of the guide roller of the special wire drawing machine to polish one surface of the base film 1, Perform surface drawing 2 treatment, wherein the particle size of the corundum is 600-1000 μm. By selecting corundum with different particle sizes, drawing lines with different depths and densities are formed on the surface of the base film 1; after the surface drawing 2 is completed, pass corona 3. The machine performs corona treatment on both surfaces of the base film 1 to increase the surface dyne coefficient of the film due to the surface drawing 2. The surface dyne coefficient of the PET fil...

Embodiment 2

[0036] The manufacturing process of the imitation stainless steel metal wire drawing film disclosed by the present invention, the mass ratio of its UV varnish: UV matting agent: oily pigment is 50:50:10, so as to obtain the wire drawing film with a semi-matte gloss on the surface, this embodiment The unmentioned technical features adopt the technical features described in Embodiment 1, and will not be repeated here.

Embodiment 3

[0038] The production process of the imitation stainless steel metal wire drawing film disclosed by the present invention, the mass ratio of its UV varnish: UV matting agent: oily pigment is 70:30:20, in order to obtain the wire drawing film with a seven-point matte gloss on the surface, this implementation For the technical features not mentioned in this example, the technical features described in Example 1 are adopted, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com