Technology for preparing 2-ethylanthraquinone

A technology for producing ethylanthraquinone and a production process, which is applied in the field of production process for 2-ethylanthraquinone, can solve problems such as inability to realize large-scale industrial production, difficult sources of raw materials, cumbersome synthesis steps, etc., achieve low cost and increase production efficiency, easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

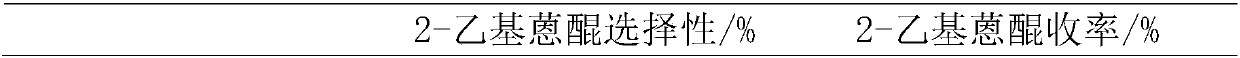

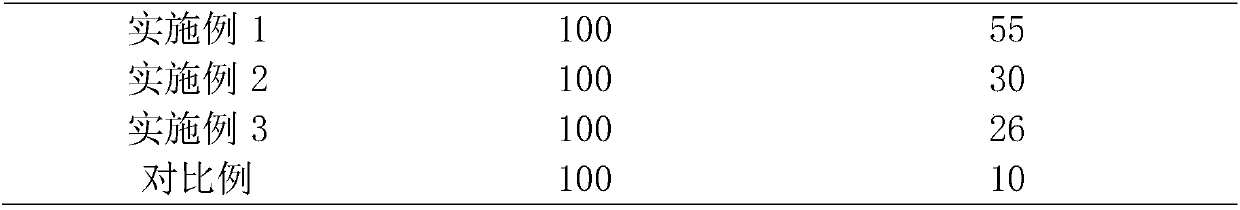

Embodiment 1

[0036] Step 1. Preparation of 2-ethylanthracene:

[0037] Mix the raw material MWW structure molecular sieve, transition metal salt solution, tetramethylammonium hydroxide, pentamethyleneimine, and deionized water uniformly to obtain the ratio of the amount of substances as H 2 0 / Si0 2 = 5, R1 / Si0 2 = 0.015, R2 / Si0 2 =0.5, and the mixture was crystallized at 180°C for 5h and recovered. The prepared catalyst was contacted and reacted with anthracene and ethylene at a temperature of 180°C and a pressure of 1MPa to obtain 2-ethyl Anthracene

[0038] Step 2. Preparation of 2-ethylanthraquinone. The Y-type molecular sieve catalyst is treated in glycerol at 150°C for 5 hours, and then mixed with the resulting mixture, inorganic directing agent, and transition metal salt solution at 80°C for 2 hours, and then placed in a closed reactor Treated at 120°C for 20h, take out the product under normal temperature and pressure, dry and roast to obtain mesoporous Y-type molecular sieve with a pore...

Embodiment 2

[0040] Step 1. Preparation of 2-ethylanthracene. A conventional MWW structure catalyst is reacted with anthracene and ethylene at a temperature of 180°C and a pressure of 1MPa to obtain 2-ethylanthracene;

[0041] Step 2. Preparation of 2-ethylanthraquinone. The Y-type molecular sieve catalyst is treated in glycerol at 150°C for 5 hours, and then mixed with the resulting mixture, inorganic directing agent, and transition metal salt solution at 80°C for 2 hours, and then placed in a closed reactor Treated at 120℃ for 20h, take out the product under normal temperature and pressure, dry and calcined to obtain mesoporous Y molecular sieve with pore diameter centered on 5-7nm; the mass mixing ratio of Y molecular sieve and glycerol is 1:5, Y molecular sieve and inorganic The mass mixing ratio of the directing agent is 1:0.5. Under the conditions of a temperature of 180°C and a pressure of 1 MPa, 2-ethylanthracene and hydrogen peroxide are contacted and reacted with the prepared catalys...

Embodiment 3

[0043] Step 1. Preparation of 2-ethylanthracene. The raw material MWW structure molecular sieve, transition metal salt solution, nitrogen-containing organic base Rl, organic amine R2, and deionized water are mixed uniformly to obtain the ratio of the amount of substance to H 2 0 / Si0 2 = 5, R1 / Si0 2 = 0.015, R 2 / Si0 2 =0.5, and the mixture was crystallized at 180°C for 5h and recovered. The prepared catalyst was contacted and reacted with anthracene and ethylene at a temperature of 180°C and a pressure of 1MPa to obtain 2-ethyl Anthracene

[0044] Step 2. Preparation of 2-ethylanthraquinone. At a temperature of 180°C and a pressure of 1MPa, 2-ethylanthracene and hydrogen peroxide are contacted and reacted with a conventional mesoporous Y-type molecular sieve catalyst to obtain 2- Ethyl anthraquinone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com