Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

A technology of alkyd resin emulsion and epoxy resin, which is applied in dyeing, coating, textile and paper making, etc., can solve the problems of high energy consumption, low production efficiency and high cost, and achieve simple production process and chemical resistance Good, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

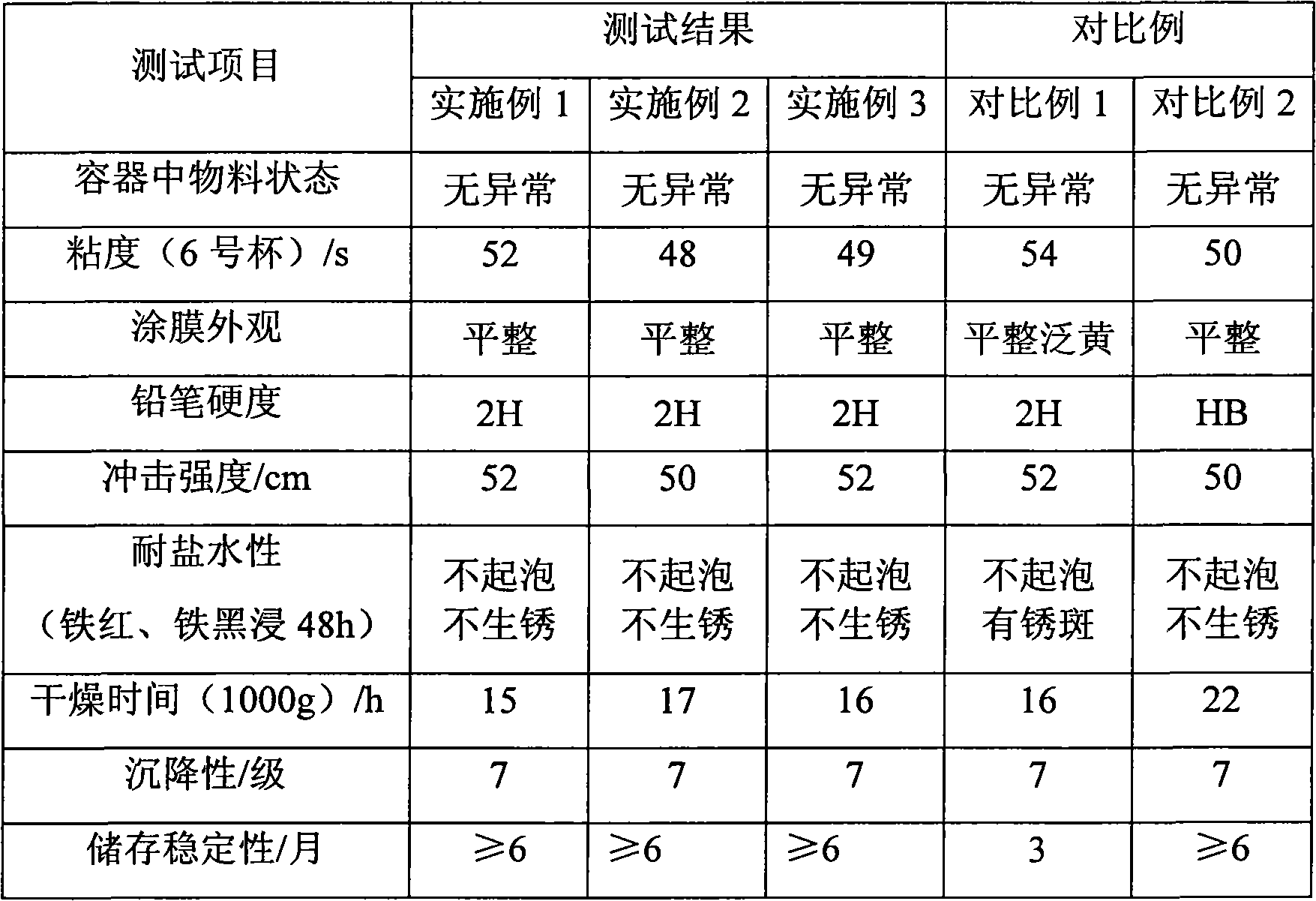

Examples

Embodiment 1

[0048] Put 200g of linseed oil, 90g of glycerin, 50g of epoxy resin E-20, 0.5g of triphenylphosphine, and 0.05g of lithium hydroxide into the reaction vessel, protect it with nitrogen, and gradually heat up to 220°C for alcoholysis reaction. When 95% When the ethanol tolerance reaches 1:5, lower the temperature to 200°C, add 26.7g of phthalic anhydride to the reaction system every half hour, add three times, the total amount of phthalic anhydride added is 80g, and remove the water generated by the reaction through the water separator. When the acid value of the system is ≤5mgKOH / g and the temperature is lowered to 75°C, start to drop 190g of acrylic monomer, 1.2g of γ-methacryloxypropyltrimethoxysilane (KH570) and 2.5g of benzoyl peroxide (BPO) mixture, the dropwise addition time is 2.5h, after the dropwise addition is completed, keep the temperature for 3-5h. The solvent and residual monomers in the reaction system were vacuumed off. Cool down to 60°C, add 65g of triethylami...

Embodiment 2

[0050]Put 180g of soybean oil, 80g of pentaerythritol, 50g of epoxy resin E-20, 0.5g of triphenylphosphine, and 0.08g of lead oxide into a reaction vessel, protect it with nitrogen, and gradually raise the temperature to 230°C for alcoholysis reaction. When 95% ethanol tolerates When the temperature reaches 1:10, turn down the temperature to 200°C, add 26.7g of phthalic anhydride to the reaction system every half hour, add three times, the total amount of phthalic anhydride added is 80g, and remove the water generated by the reaction through the water separator. When the acid value of the system is less than or equal to 5mgKOH / g and the temperature is lowered to 80°C, start to drop 160g of acrylic monomer, 1.2g of γ-methacryloxypropyltrimethoxysilane (KH570) and 2.2g of benzoyl peroxide (BPO) mixture, the dropwise addition time is 2, after the dropwise addition is completed, keep warm for 3-5h. The solvent and residual monomers in the reaction system were vacuumed off. Cool d...

Embodiment 3

[0052] Put 300g of linseed oil, 120g of glycerin, 130g of epoxy resin E-12, 1.5g of triphenylphosphine and 1.0g of calcium naphthenate into a reaction vessel, protect it with nitrogen, and gradually raise the temperature to 225°C for alcoholysis. When the tolerance of 95% ethanol reaches 1:10, turn down the temperature to 200°C, add 60g of phthalic anhydride to the reaction system every half hour, add three times, the total amount of phthalic anhydride added is 180g, and remove the water generated by the reaction through the water separator. When the acid value of the system is ≤5mgKOH / g and the temperature is lowered to 76°C, start to drop 280g of acrylic monomer, 1.6g of γ-methacryloxypropyltrimethoxysilane (KH570) and 3.0g of benzoyl peroxide (BPO) mixture, the dropwise addition time is 3h, after the dropwise addition is completed, keep warm for 4h. The solvent and residual monomers in the reaction system were vacuumed off. Cool down to 55°C, add 96g of 2-amino-1-propanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com