Novel methods for simultaneously extracting tea polyphenol, tea polysaccharide and caffeinum from tea

A technology for tea polyphenols and caffeine, applied in the field of simultaneous extraction of tea polyphenols, tea polysaccharides, and caffeine, can solve the problems of toxic safety factor, low extraction rate, low product purity, etc., to ensure safety and reliability, The effect of improving extraction rate and purity and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

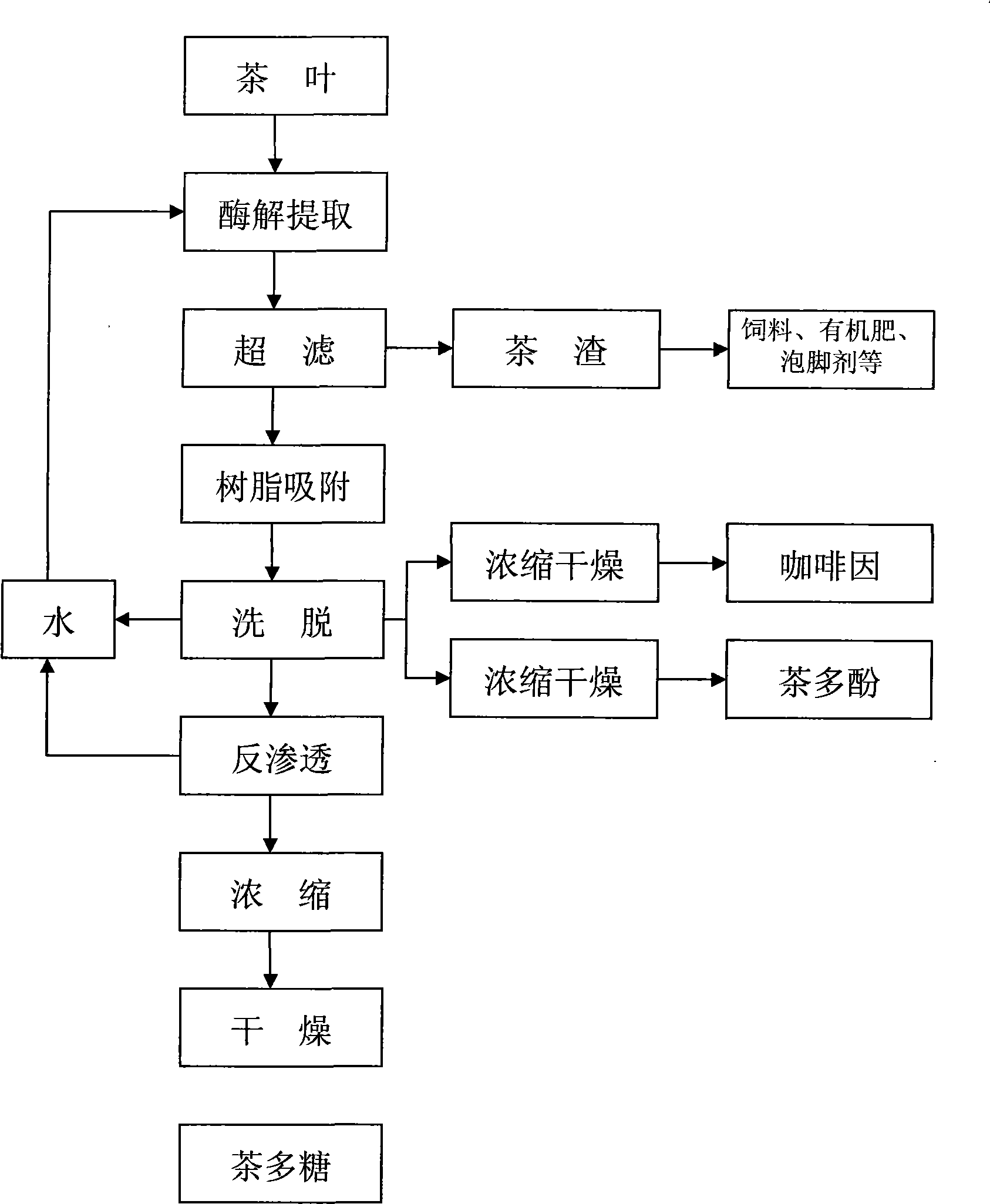

Method used

Image

Examples

Embodiment 1

[0034] Use 10kg of tea leaves (low-grade tea, coarse old tea leaves, discarded branches and leaves pruned in tea gardens, waste leftovers in tea production), after crushing to 80-100 mesh, add 150kg of water, heat up to 50 degrees, add 30g of compound enzyme (neutral Protease: papain: trypsin weight ratio 2:1:1), keep the temperature constant, extract for 60 minutes, add water 10kg to the tea dregs after filtering, keep the temperature constant at 50 degrees, then extract for 30 minutes. Combine the two leached solutions, add protein remover (sodium chloride) 5g, and stir for 30 minutes. At room temperature to 40 degrees, use 0.1μm-0.3μm ultrafiltration membrane for ultrafiltration, the inlet and outlet pressure ratio is 0.2-0.4mpa, the cut-off flow is 10ml / min, and the ultrafiltration membrane has a molecular weight of 5000- 10000, because the filtered tea residue has been enzymatically hydrolyzed, it can be used as animal feed, organic compound fertilizer or foot soak agent,...

Embodiment 2

[0038] Use 10kg of tea leaves (low-grade tea, coarse old tea leaves, discarded branches and leaves pruned in tea gardens, waste leftovers in tea production), after crushing to 80-100 mesh, add 160kg of water, heat up to 50 degrees, add 25g of compound enzyme (neutral Protease: xylanase: trypsin weight ratio 2:1:1), keep the temperature constant, extract for 60 minutes, add water 10kg to the filtered tea dregs, keep the temperature constant at 50 degrees, and then extract for 30 minutes. Combine the two leached solutions, add 5 g of protein remover (sodium chloride), and stir for 30 minutes. Cool at room temperature to 40 degrees, use 0.1μm-0.3μm ultrafiltration membrane for ultrafiltration, the inlet and outlet pressure ratio is 0.2-0.4mpa, the interception flow is 10ml / min, and the ultrafiltration membrane has a molecular weight of 10000—15000 (the filtered tea residue is enzymatically hydrolyzed and used as animal feed, organic compound fertilizer or foot soak agent, etc., t...

Embodiment 3

[0041] Use 10kg of tea leaves (low-grade tea, coarse old tea leaves, discarded branches and leaves pruned in tea gardens, waste leftovers in tea production), after crushing to 80-100 mesh, add 170kg of water, heat up to 50 degrees, add 35g of compound enzyme (neutral Protease: papain: dextranase weight ratio 2:1:1), keep the temperature constant, leaching for 60 minutes, add 10-15kg of water to the filtered tea dregs, keep the temperature at 50 degrees, and then leaching for 30 minutes minute. Combine the two leached solutions, add 5 g of protein remover (sodium chloride), and stir for 30 minutes. At room temperature to 40 degrees, use 0.1μm-0.3μm ultrafiltration membrane for ultrafiltration, the inlet and outlet pressure ratio is 0.2-0.4mpa, the interception flow is 10ml / min, and the molecular weight of the ultrafiltration membrane is 15000- 20000 (filtered tea dregs have been enzymatically hydrolyzed and used as animal feed, organic compound fertilizer or foot soak agent, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com