High-whiteness pure color full-body polishing brick, and production method and application thereof

A production method and high whiteness technology, applied in construction, covering/lining, building construction, etc., can solve the problems of low luminosity of high-magnesium ceramic tiles, difficult to form mass production, poor wear resistance of glazed tiles, etc. Good antifouling performance, reduced product cost, and excellent quality fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

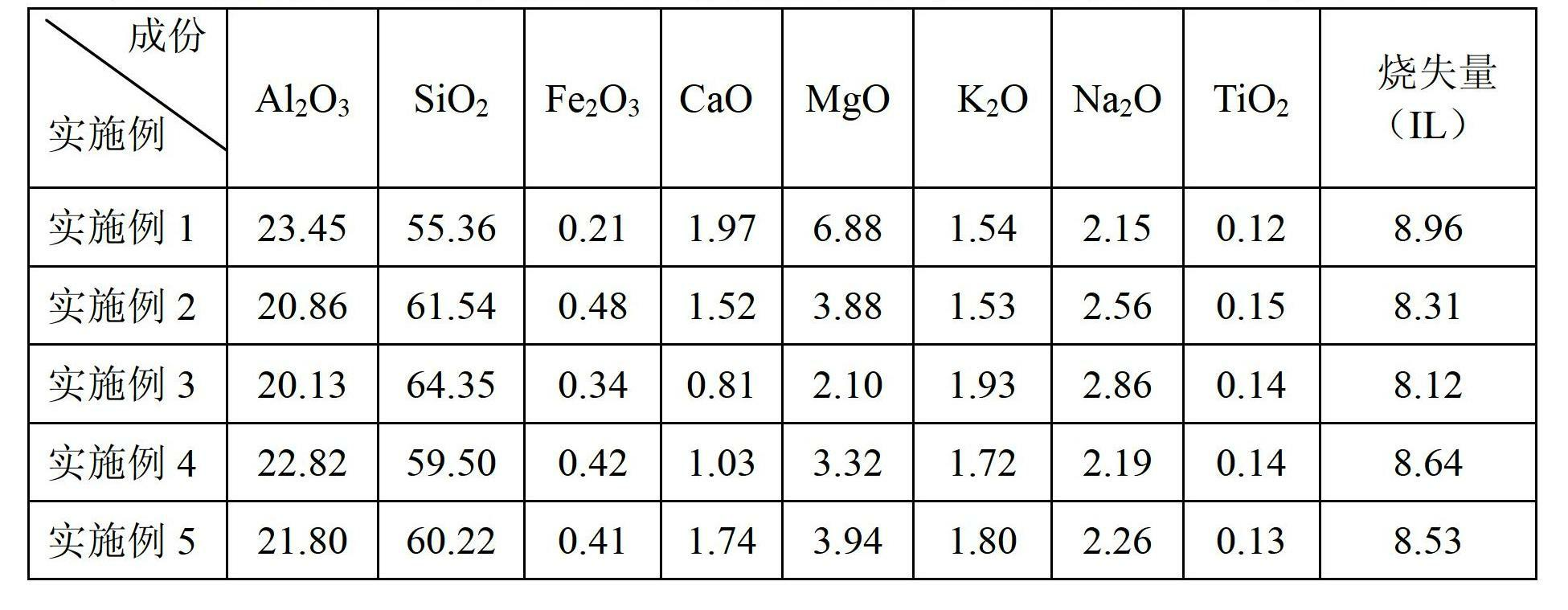

[0051] A high-whiteness solid-color full-body polished tile, the raw material formula of which is shown in Table 1:

[0052] Table 1 Raw material formula of the high-whiteness solid-color full-body polished tiles of Examples 1-5 (unit: %)

[0053] raw material name

Example 1

Example 2

Example 3

Example 4

Example 5

20

24.4

30

21

30

high temperature sand

17.35

10

28

19

10

high white clay

20

27

23.38

22.35

22

Quartz sand

4

12

0

6

8

Aluminum powder

20

11

10

18

15

Calcined talcum powder

18

15

8

13

14.35

sodium tripolyphosphate

0.5

0.5

0.5

0.5

0.5

Methylcellulose

0.15

0.1

0.12

0.15

0.15

[0054] Its production method comprises the following steps:

[0055] (1) Weigh each raw material ...

Embodiment 1

[0066] Example 1: The shrinkage rate is 11.3%, the water absorption rate is 0.1%, the antifouling grade is 4, and the whiteness reaches 73-75°, which solves the problems caused by the introduction of zirconium silicate and other chemical materials into traditional ultra-white bricks for whitening. Radiation Hazard.

Embodiment 2

[0067] Example 2: The shrinkage rate is 9.3%, the water absorption rate is 0.08%, the antifouling grade is 4, and the whiteness reaches 69-71°. Radiation Hazard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com