Dyeing process for modal/cotton blended fabric

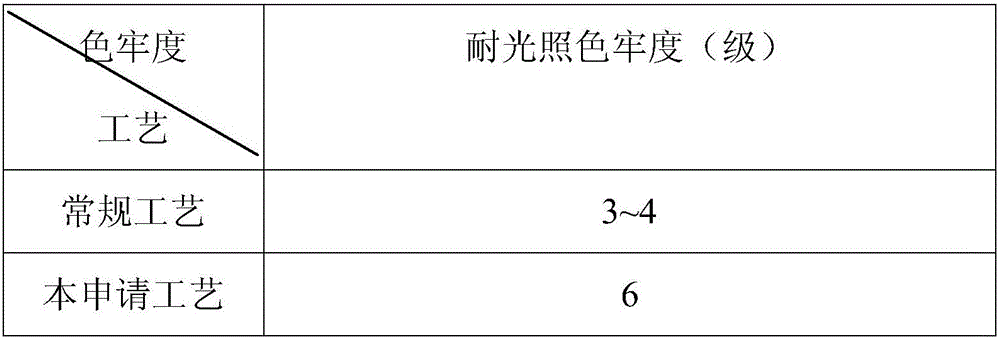

A fabric dyeing and cotton blending technology, applied in the field of dyeing and finishing technology, can solve the problems affecting the quality of plain cloth, uneven color of cloth, easy to scratch and fluff strength, etc., to achieve bright color, excellent color fastness, Good level dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

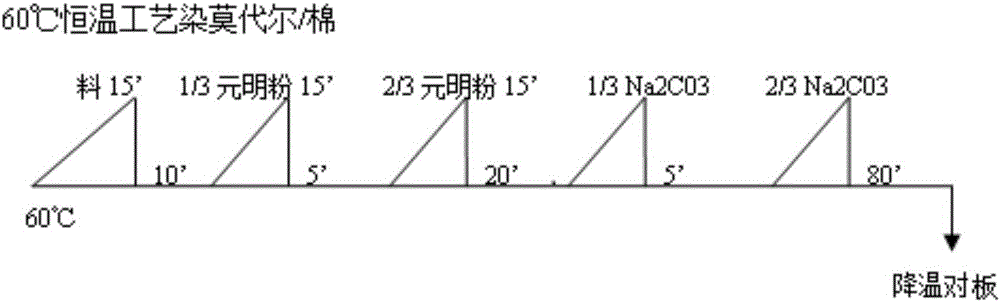

[0018] Embodiment 1: as figure 1 Shown, a kind of Modal / cotton blended fabric dyeing process, concrete process comprises the following steps:

[0019] (a) Pre-treatment: Put 167kg of 40S50 / 50 cotton modal + 20D single jersey fabric in the Fong’s ECO-38 2T cylinder, enter water, keep the bath ratio 1:9, add 3% Baixue cleaning cotton enzyme to raise the temperature to Run at 98°C for 30 minutes, drain water; add 0.4% glacial acetic acid to the water at a bath ratio of 1:9, and run cold at room temperature for 10 minutes; drain water; keep the bath ratio at 1:9 again, add 0.12% deoxygenase, and run cold at room temperature 10min;

[0020] (b) Dyeing: Dye the fabric with a 60°C constant temperature dyeing process, and use a 60°C constant temperature dyeing process to dye the modal / cotton blended fabric: put the modal / cotton blended fabric in a dye vat, and keep the bath ratio of 1: 9. Heat up to 60°C and keep constant temperature, add 1.45% Avitra SE yellow, 1.9% Avitra SE red, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com