Alga polyester composite fiber and preparation method and application thereof

A composite fiber and polyester fiber technology, applied in the direction of fiber treatment, fiber type, improved hand feeling fiber, etc., can solve the problems of high dyeing difficulty, non-degradability, poor hygroscopicity of polyester fiber, etc., to increase the fixation fastness, Improve dyeing performance, fiber more effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

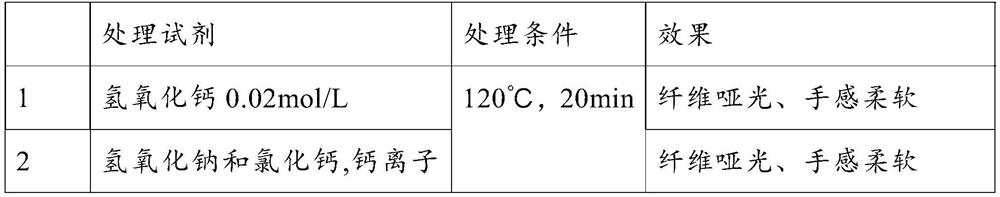

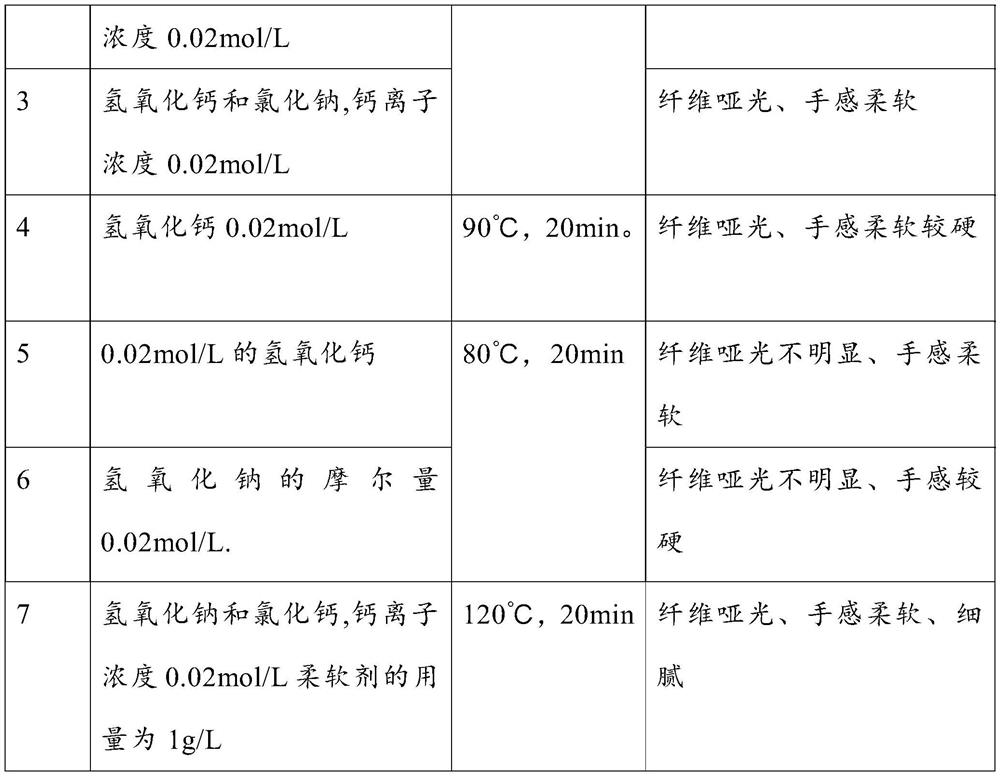

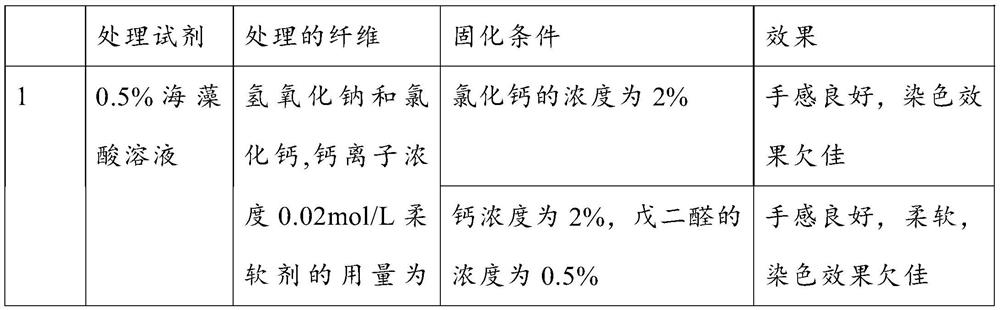

Examples

Embodiment Construction

[0103] In order to enable those skilled in the art to better understand the technical solution of the present disclosure, the following will give a further detailed introduction to the solution of the present disclosure.

[0104] The present disclosure first explains the nouns or reagents used in the present disclosure,

[0105] The disclosed process is a brand-new process, and the treatment process has high efficiency, and the composite fiber has excellent dyeing performance and antibacterial performance, and has good absorbing performance at the same time.

[0106] The word seaweed used in the "seaweed / polyester composite fiber" described in this disclosure is mainly calcium alginate, and the presence of a small amount of possibly solidified sodium alginate is not excluded.

[0107] The seaweed solution used in step (2) of the present disclosure mainly refers to sodium alginate. Those skilled in the art know that both alginic acid and calcium alginate are insoluble in water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com