Using method and apparatus for petroleum coke powder fuel for smelting glass

A technology of petroleum coke powder and molten glass, which is applied in glass furnace equipment, glass manufacturing equipment, fuel, etc., can solve the problems that factories cannot bear, affect the whiteness of glass, and high price, so as to reduce manufacturing cost, improve utilization rate, and improve production efficiency. The effect of price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

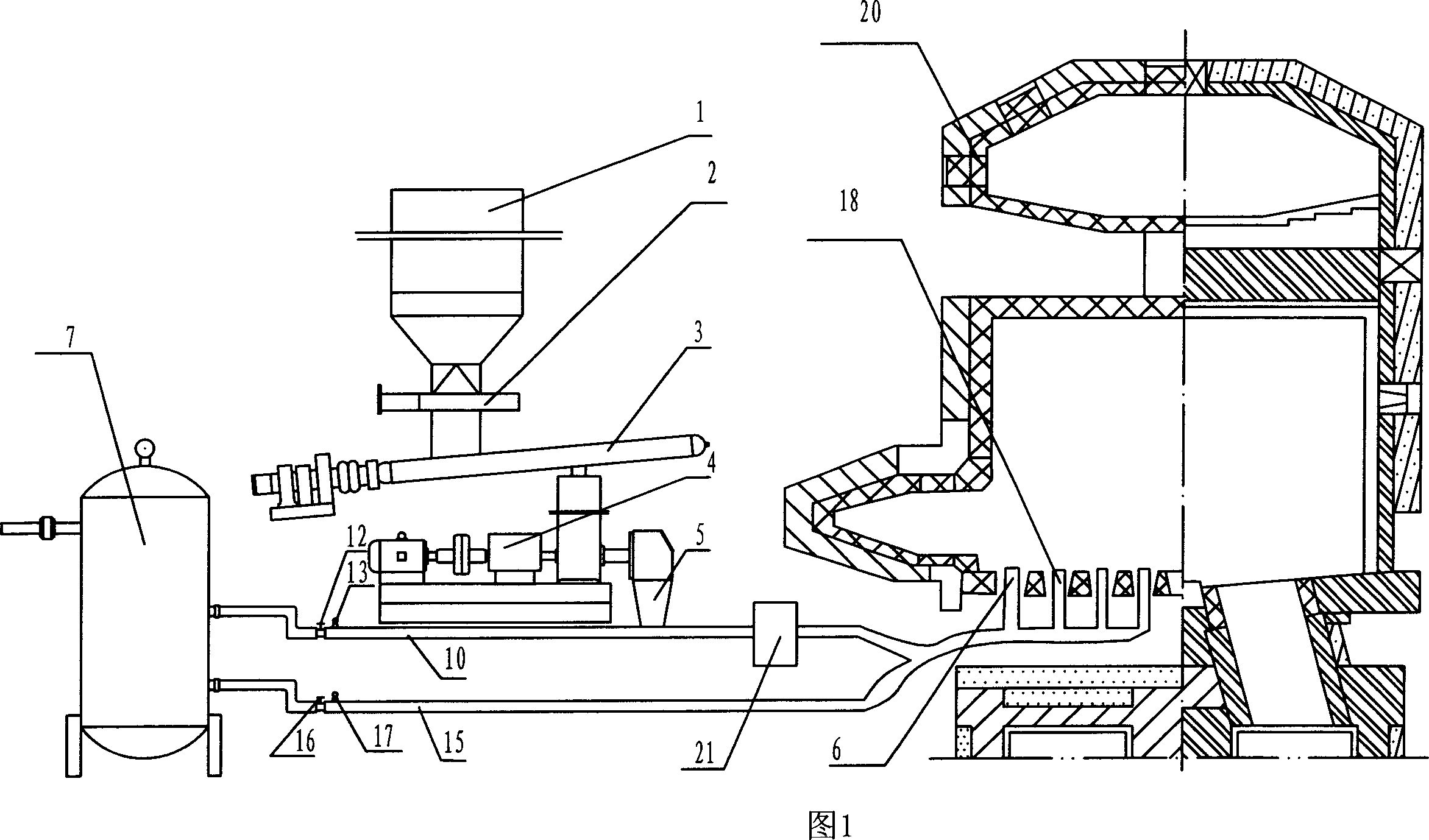

[0023] A method for using petroleum coke powder fuel for molten glass, the method comprising the following steps:

[0024] Step ① Fuel screening: remove impurities in petroleum coke,

[0025] Step 2. Fuel pulverization: pulverize petroleum coke with a crusher to obtain coarse petroleum coke with a particle size of less than 25mm.

[0026] Step 3. Fuel grinding: Grinding coarse petroleum coke particles to obtain petroleum coke powder with a particle size of 150-1000 meshes.

[0027] Step ④ fuel iron removal: the petroleum coke powder obtained in step ③ is subjected to iron removal treatment through a magnetic field to obtain petroleum coke powder with an iron content of less than 1 / 10,000.

[0028] Step 5. Fuel drying: dry the petroleum coke powder fuel so that the water content of the fuel is less than 8%.

[0029] Step 6. Fuel delivery: the petroleum coke powder fuel is delivered to the powder feeder 4,

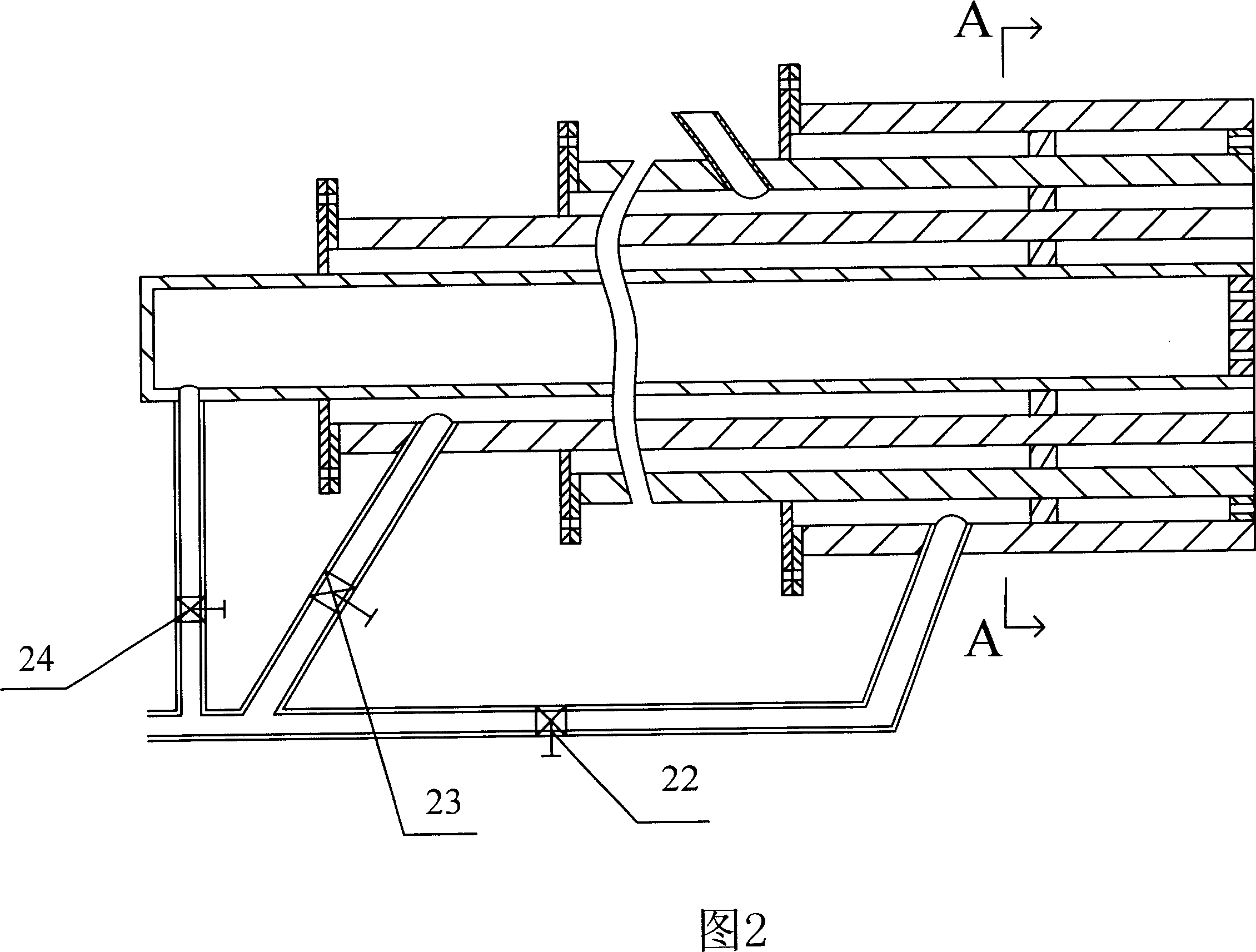

[0030] Step 7. premixing of fuel and air: petroleum coke powder fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com