Method for producing beta-high-purity gypsum powder by using phosphogypsum

A technology of phosphogypsum and gypsum powder, which is applied in the field of phosphogypsum production of β-high-purity gypsum powder, which can solve the problems of unstable product quality, difficult temperature control, high calcination temperature, etc., to ensure whiteness and index stability, and equipment loss The effect of small, low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for producing β-high-purity gypsum powder with phosphogypsum, the steps are as follows:

[0032] (1) Dry phosphogypsum with a surface water content of ≤25% at room temperature until the free water content is ≤3%, and send it to the FC-compartment calciner for calcination for 2.5 hours. The maximum temperature in the calciner is 130°C, and the outlet material temperature is 110°C, the absolute pressure on the top of the FC-compartment calciner is 99.0KPa~100.2KPa;

[0033] (2) The material calcined in step (1) is crushed by a primary crushing device to a particle size of ≤125 microns, with a sieve residue of ≤3.00%;

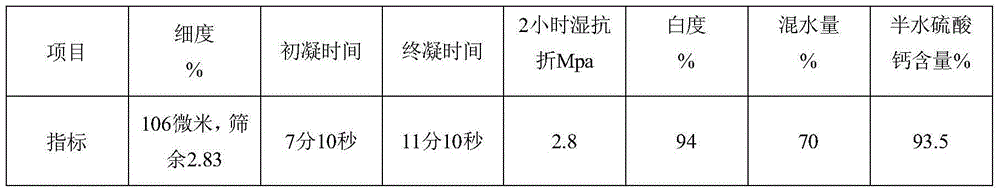

[0034] (3) Send the material obtained in step (2) into an airtight aging warehouse, and airtightly age it at room temperature for 3 days. The aged material is crushed by a secondary crushing device, and the particle size grade is 106 microns (screen residue ≤ 3.00 %) and materials with a particle size grade of 95 microns (residual sieve ≤ 3.00%) a...

Embodiment 2

[0039] A method for producing β-high-purity gypsum powder with phosphogypsum, the steps are as follows:

[0040] (1) Dry phosphogypsum with a surface water content of ≤25% at room temperature until the free water content is ≤3%, and send it to the FC-compartment calciner for calcination for 2.8 hours. The maximum temperature in the calciner is 135°C, and the outlet material temperature is The temperature is 115°C, and the absolute pressure on the top of the FC-compartment calciner is 99.0KPa~100.2KPa;

[0041] (2) The material calcined in step (1) is crushed by a primary crushing device to a particle size of ≤125 microns, with a sieve residue of ≤3.00%;

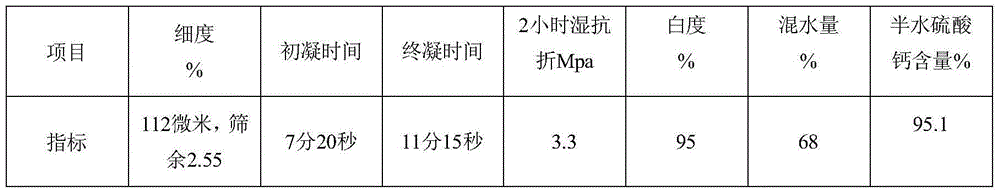

[0042] (3) Send the material obtained in step (2) into an airtight aging warehouse, and airtightly age it at room temperature for 4 days. The aged material is crushed by a secondary crushing device, and the particle size grade is 112 microns (screen residue ≤ 3.00 %) and material with a particle size grade of 90 microns (res...

Embodiment 3

[0047] A method for producing β-high-purity gypsum powder with phosphogypsum, the steps are as follows:

[0048] (1) Dry phosphogypsum with a surface water content of ≤25% at room temperature until the free water content is ≤3%, and send it to the FC-compartment calciner for calcination for 3 hours. The maximum temperature in the calciner is 140°C, and the outlet material temperature is The temperature is 120°C, and the absolute pressure on the top of the FC-compartment calciner is 99.0KPa~100.2KPa;

[0049] (2) The material calcined in step (1) is crushed by a primary crushing device to a particle size of ≤125 microns, with a sieve residue of ≤3.00%;

[0050] (3) Send the material obtained in step (2) into an airtight aging warehouse, and airtightly age it at room temperature for 5 days. The aged material is crushed by a secondary crushing device, and the particle size grade is 120 microns (screen residue≤3.00 %) and the material with a particle size grade of 110 microns (re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com