Polyolefin polyol modified thermoplastic polyurethane elastomer and preparation method thereof

A technology of polyolefin polyol and thermoplastic polyurethane, which is applied in the field of polyolefin polyol modified thermoplastic polyurethane elastomer and its preparation, can solve the problems of low hydrolysis stability and large dynamic heat generation, and achieves improved hydrolysis resistance and other properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

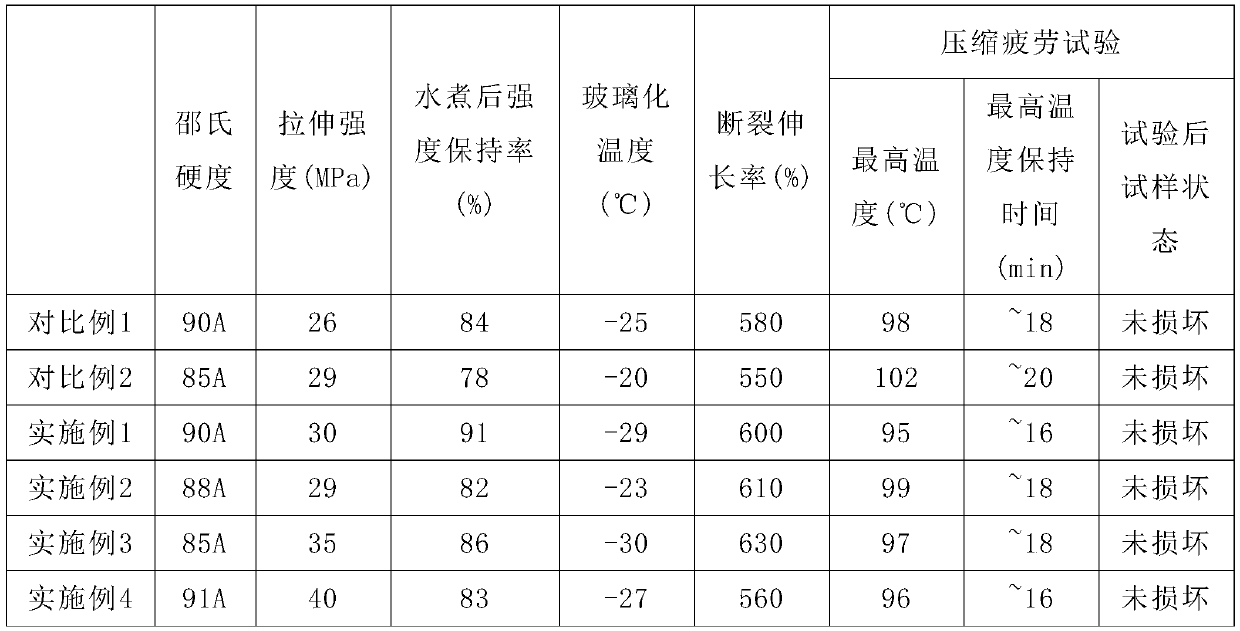

Embodiment 1

[0032] The preparation method of the thermoplastic polyurethane elastomer modified by polyolefin polyol comprises the following steps: (1) taking by weight 20 parts of predried polybutadiene polyol with a molecular weight of about 1000 and 40 parts of predried Mix and stir polytetrahydrofuran polyol with a molecular weight of about 1000g / mol evenly, add 33.4 parts of diphenylmethane diisocyanate into the reaction vessel, heat up to 80°C under constant stirring, and perform a vacuum reaction; (2) Release the vacuum , add 6.6 parts of pre-dried butanediol, stir quickly, the temperature of the material gradually rises to 120 ° C, the viscosity increases significantly, stop stirring, pour it into a polytetrafluoroethylene tray, mature, cool and crush to obtain modified thermoplastic polyurethane elastomer.

Embodiment 2

[0034] The preparation method of the thermoplastic polyurethane elastomer modified by polyolefin polyol comprises the following steps: (1) the pre-dried molecular weight of 30 parts by weight is 2000 hydroxyl-terminated polybutadiene-acrylonitrile and 30 parts The pre-dried polyester polyol with a molecular weight of about 2000g / mol was mixed and stirred evenly, and 33.9 parts of hydrogenated phenylalkyl diisocyanate was added to the reaction vessel, and the temperature was raised to 80°C under constant stirring, and the vacuum reaction was carried out; ( 2) Remove the vacuum, add 6.1 parts of pre-dried ethylene glycol, stir rapidly, the temperature of the material gradually rises to 120 ° C, the viscosity increases significantly, stop stirring, pour it into a polytetrafluoroethylene tray, mature, cool and crush to obtain improved A thermoplastic polyurethane elastomer.

Embodiment 3

[0036] The preparation method of the thermoplastic polyurethane elastomer modified by polyolefin polyol comprises the following steps: (1) taking by weight the pre-dried molecular weight of 25 parts is the hydroxy-terminated styrene-butadiene liquid rubber of 3000 and 25 parts of pre-dried styrene-butadiene liquid rubber The polyester polyol with a molecular weight of about 2000g / mol is mixed and stirred evenly, and 21.7 parts of hexamethylene diisocyanate are added to the reaction container, and the temperature is raised to 75°C under constant stirring, and the vacuum reaction is performed; (2) Release the vacuum , add 13.1 parts of pre-dried hexanediol, stir quickly, the temperature of the material gradually rises to 115°C, the viscosity increases significantly, stop stirring, pour it into a polytetrafluoroethylene tray, mature, cool and pulverize to obtain modified thermoplastic polyurethane elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com