Metal surface treatment agent

A technology of metal surface treatment and silane coupling agent, applied in the field of phosphorus-free metal surface treatment agent, can solve problems such as excessive corrosion of plates, and achieve the effects of improving adhesion, improving weather resistance and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

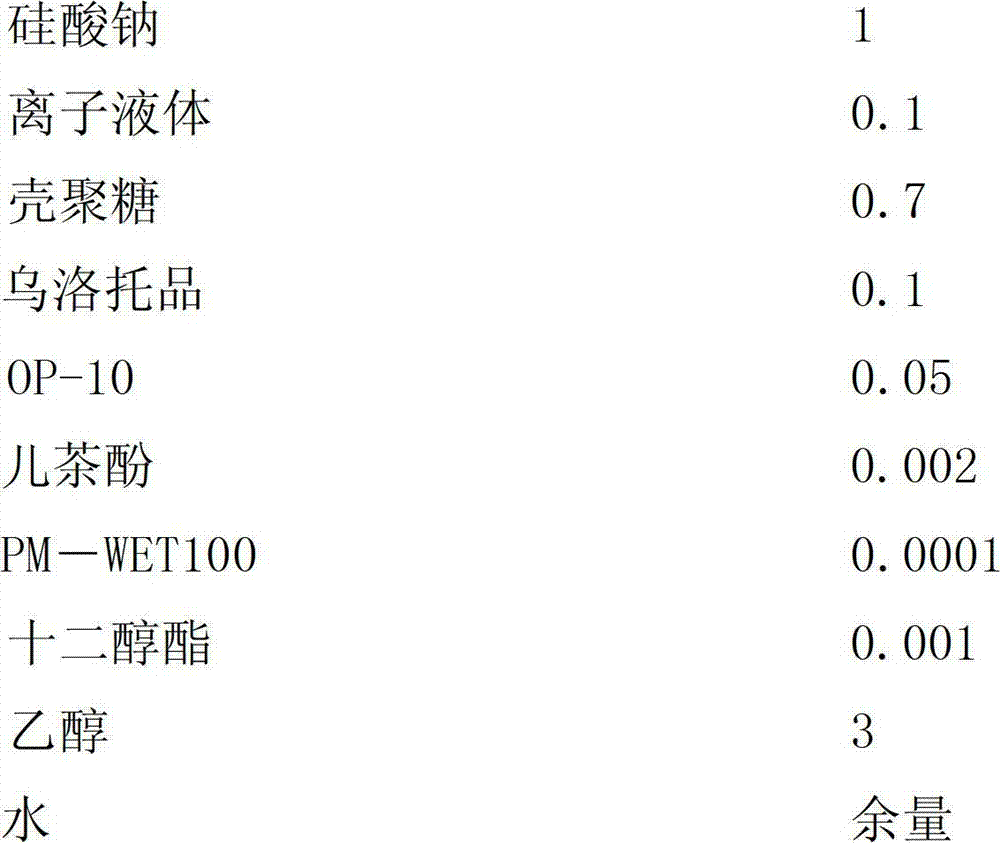

Embodiment 1

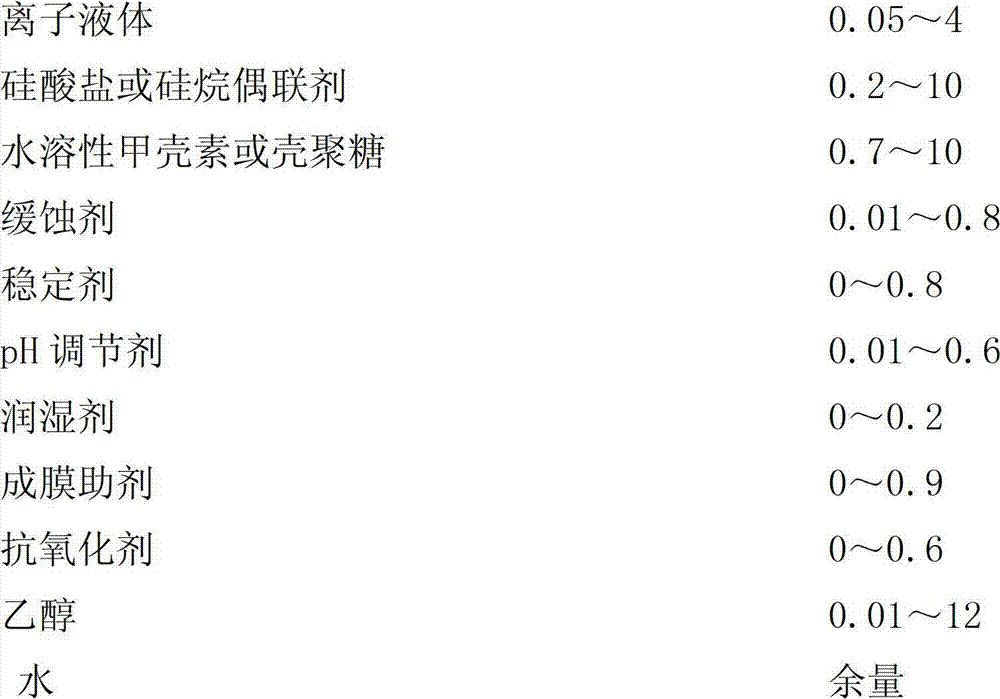

[0043] A metal surface treatment agent comprises the following components by weight percentage:

[0044]

[0045] Nano-zirconium dioxide equivalent to 3% of its mass is uniformly mixed in the sodium silicate; the ionic liquid is a brominated 1-butyl-3-methylimidazole ionic liquid; The degree of acetylation is 70%, and the average molecular weight is 1.3×10 6 ; The main component of the OP-10 is alkylphenol polyoxyethylene ether. The pH of the above composition was adjusted to 5.0 with oxalic acid.

[0046] The metal test pieces to be processed are the 5082 aluminum plate of Zhongwang Aluminum, the Q235 cold-rolled steel plate of Anshan Iron and Steel Co., Ltd., and the SGCC electro-galvanized plate of Anshan Iron and Steel Co., Ltd.

[0047] After cleaning and drying the test piece, place it in the above-mentioned metal surface treatment agent and soak for 2 minutes; take it out, dry it with hot air, spray paint, and measure the coating performance. The experimental resu...

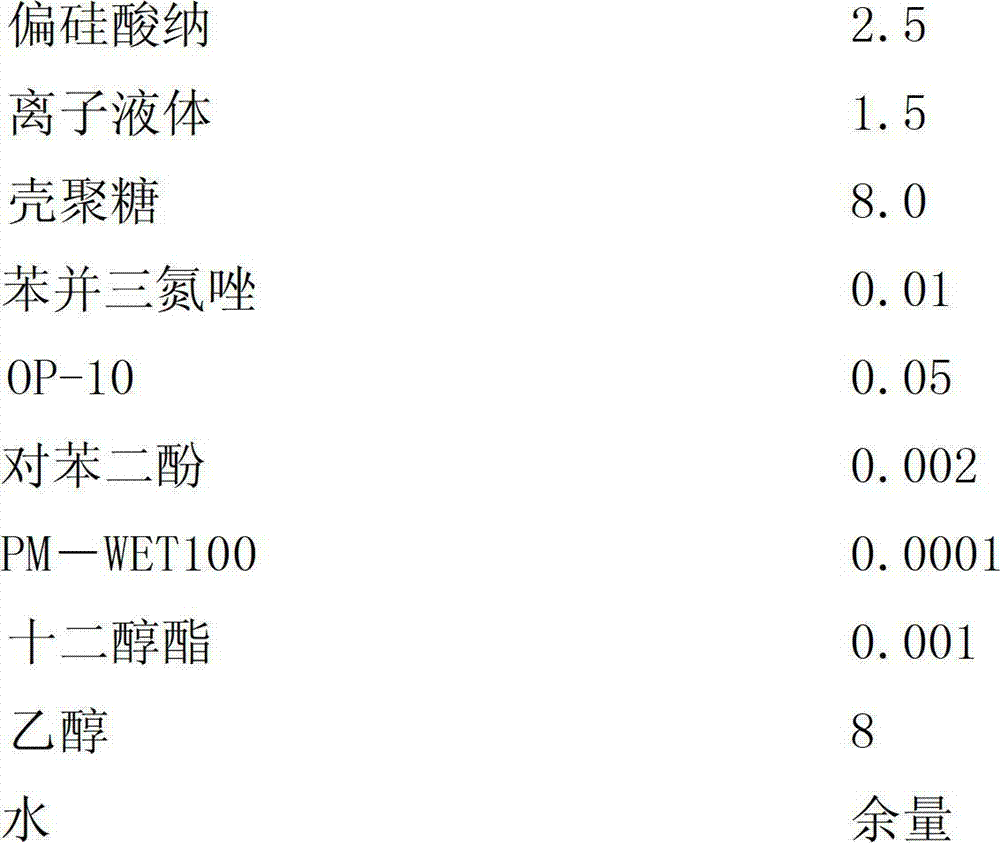

Embodiment 2

[0049] Repeat Example 1 according to the content of each component specified in Table 1, but the sodium silicate is uniformly mixed with nano-zirconia equivalent to 8% of its mass; the ionic liquid is tetrafluoroboric acid 1-butyl-3 -Methylimidazole ionic liquid; the N-deacetylation degree of the chitosan is 75%, and the average molecular weight is 1.3×10 6 .

[0050] The experimental results are shown in Table 2, Table 3 and Table 4 respectively.

Embodiment 3

[0052] Repeat Example 1 according to the content of each component specified in Table 1, and the sodium silicate is uniformly mixed with nano-titanium dioxide and zirconia equivalent to 10% of its mass; the ionic liquid is 1-butyl-hexafluorophosphate 3-methylimidazole ionic liquid; the N-deacetylation degree of the chitosan is 80%, and the average molecular weight is 1.2×10 6 .

[0053] The experimental results are shown in Table 2, Table 3 and Table 4 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com