Processing method of cylindrical component with mask micro-structure on outer curved surface

A technology of microstructure and outer curved surface, which is applied in the direction of processing electrodes, electric processing equipment, processing working media, etc., can solve the problems of cumbersome processing technology, high manufacturing cost, and low surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

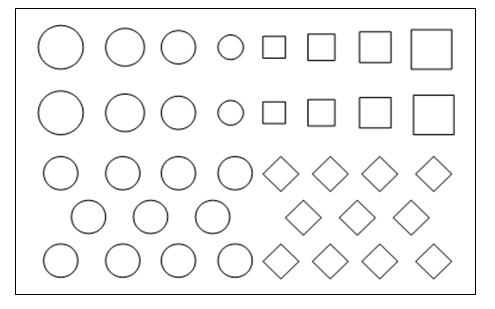

[0023] refer to figure 1 As shown, the cross-sectional shape of the insulating shielding film microstructure formed on the surface of the cylinder can be any shape such as square, circle, rhombus, etc., and the size can range from micron to millimeter.

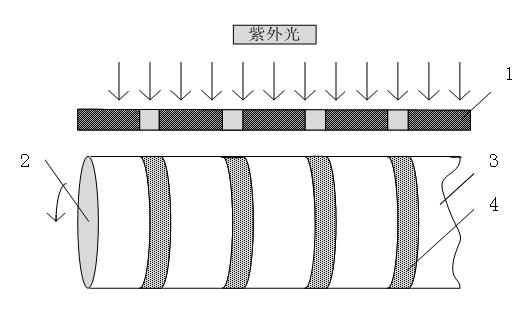

[0024] refer to figure 2 As shown, the insulating shielding film is produced by combining dip coating and rolling photolithography, and the microstructure pattern on the mask plate 1 is replicated by ultraviolet light exposure on the cylindrical part 2 coated with photoresist, that is, the exposure area 4. After development The unexposed area 3 is left, and this method makes the insulating shielding film closely adhere to the cylindrical part, which is beneficial to electrolytic processing.

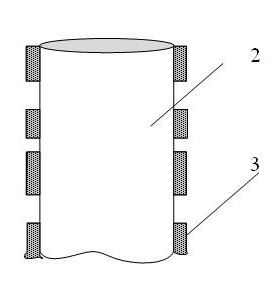

[0025] refer to image 3 As shown, the insulating shielding film 3 is made by combining dip coating and rolling ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com