Method for coarsening surface of light-emitting diode (LED) with the aid of metal nanoparticles

A metal nanoparticle, light-emitting diode technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve problems such as unfavorable commercial application, poor controllability, complex process, etc. Production cost, the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Taking the epitaxial wafer of gallium nitride-based blue light-emitting diode as an example to illustrate the implementation method of the present invention:

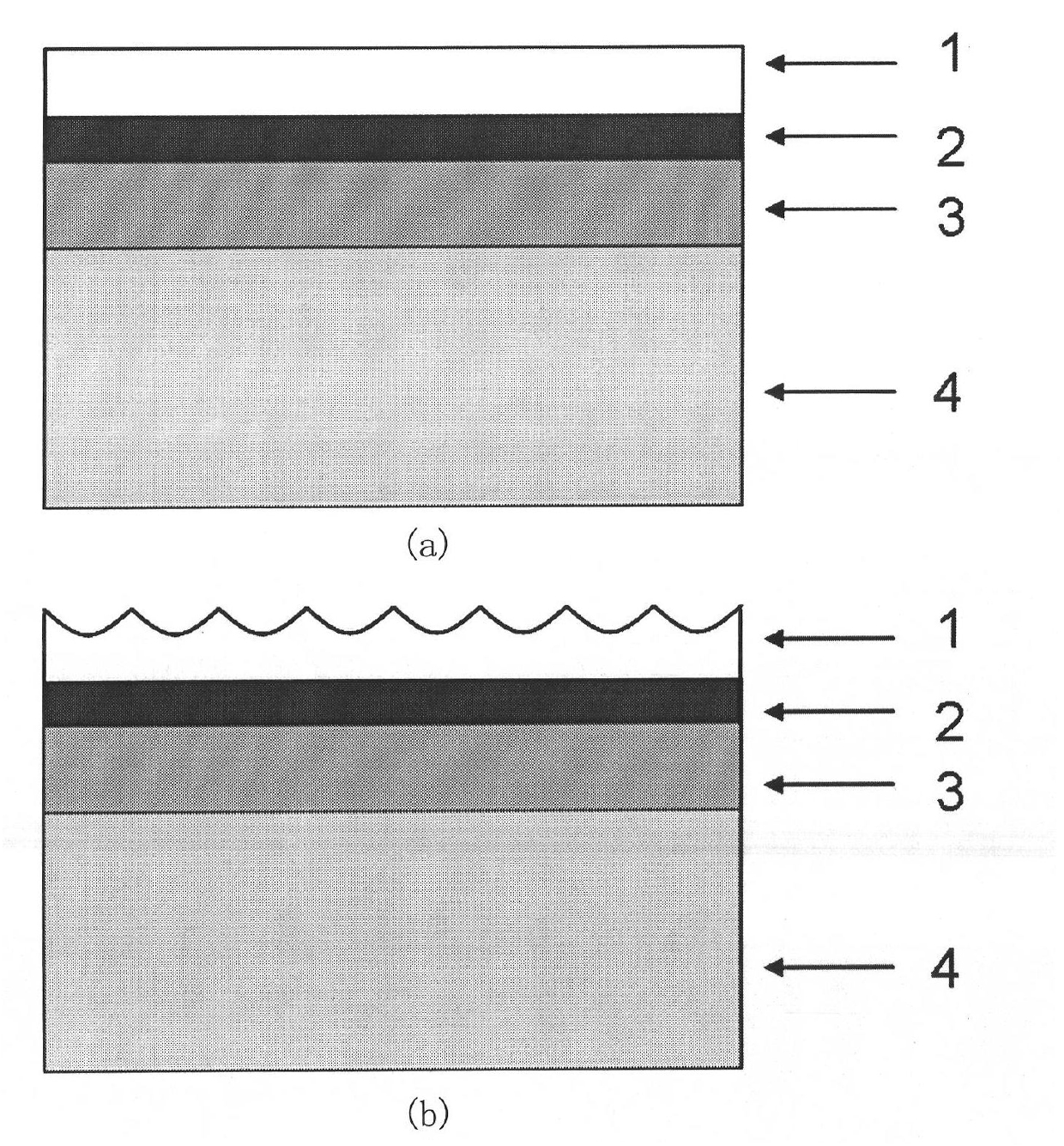

[0039] (1) On a substrate such as sapphire or silicon carbide, a buffer layer, N-GaN layer, active layer, and P-type gallium nitride layer are sequentially grown by metal-organic vapor deposition to form a gallium nitride-based light-emitting diode blue epitaxial wafer.

[0040] (2) The thickness of P-type gallium nitride is controlled to be 200nm-400nm.

[0041] (3) configure silver nitrate solution, the molar concentration of silver nitrate solution is between 0.M-1M, adopt deionized water to dissolve.

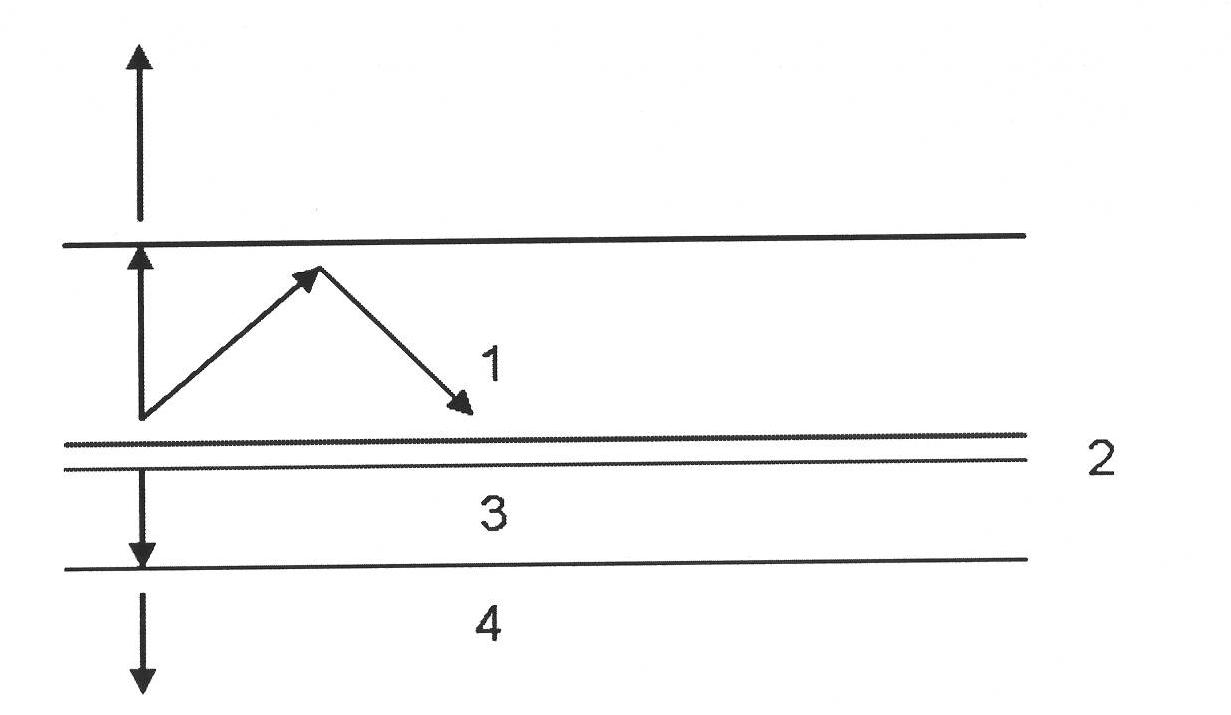

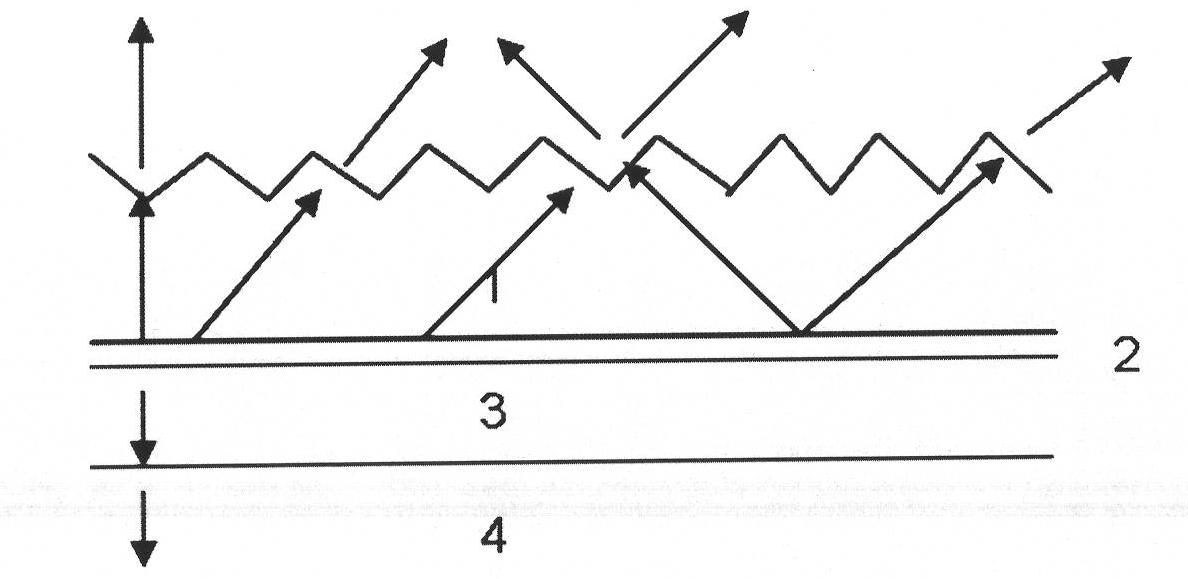

[0042] (4) Immerse the gallium nitride-based blue light epitaxial wafer in the silver nitrate solution, and deposit a layer of nano-silver on the surface of p-gallium nitride by ultraviolet light. The intensity of ultraviolet light is between 20W-100W, and the size of silver nanoparticles is 100nm-1000nm, the ...

Embodiment 2

[0051] Taking the epitaxial wafer of gallium nitride-based blue light-emitting diode as an example to illustrate the implementation method of the present invention, it is the same as in embodiment 1, except that in step (3), the metal salt solution used is potassium chloroplatinate, and then The gallium nitride-based blue light epitaxial wafer is immersed in the metal salt solution, and a layer of platinum is deposited on the surface of P gallium nitride by ultraviolet light. The intensity of ultraviolet light is between 20W-100W, and the size of platinum nanoparticles is 100nm-1000nm. The time of light irradiation is from 5min to 30min. Then adopt the same steps (5)-(11) as in Example 1 to configure the etching liquid, the etching liquid is selected hydrofluoric acid, the oxidizing agent is selected potassium bisulfate, and the mass concentration of the hydrofluoric acid solution is 10%-40 %, the molar concentration of potassium bisulfate is 0.05M-0.1M, and it is diluted with...

Embodiment 3

[0054] In this embodiment, red light AlGaInP light-emitting diodes are etched. The top layer structure of this light-emitting diode epitaxial wafer is a layer of P-GaP with a thickness of 10 μm. The metal salt solution configured is chloroauric acid or other metal salts. The epitaxial wafer is immersed in the metal salt solution, and a layer of metal nanoparticles can be deposited on the GaP surface without ultraviolet light. The size of the metal nanoparticles is 10nm-200nm. Then adopt the same steps (5)-(11) as in Example 1, hydrofluoric acid is selected for the corrosion solution, potassium bisulfate is selected for the oxidant, the mass concentration of the hydrofluoric acid solution is 10%-40%, and the mole of potassium bisulfate The concentration is 0.05M-0.1M, put the epitaxial wafer deposited with metal nanoparticles into the etching solution, and use ultraviolet light to irradiate for wet etching. The etching time is about 10min-60min, and the etching time is selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com