A highly weather-resistant, low-cost seawater corrosion-resistant steel bar and its production process

A production process and seawater resistance technology, applied in low-cost seawater corrosion-resistant steel bars and production processes, high weather resistance fields, can solve problems such as corrosion resistance, strength, aging performance research, etc., to achieve the effect of seawater corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

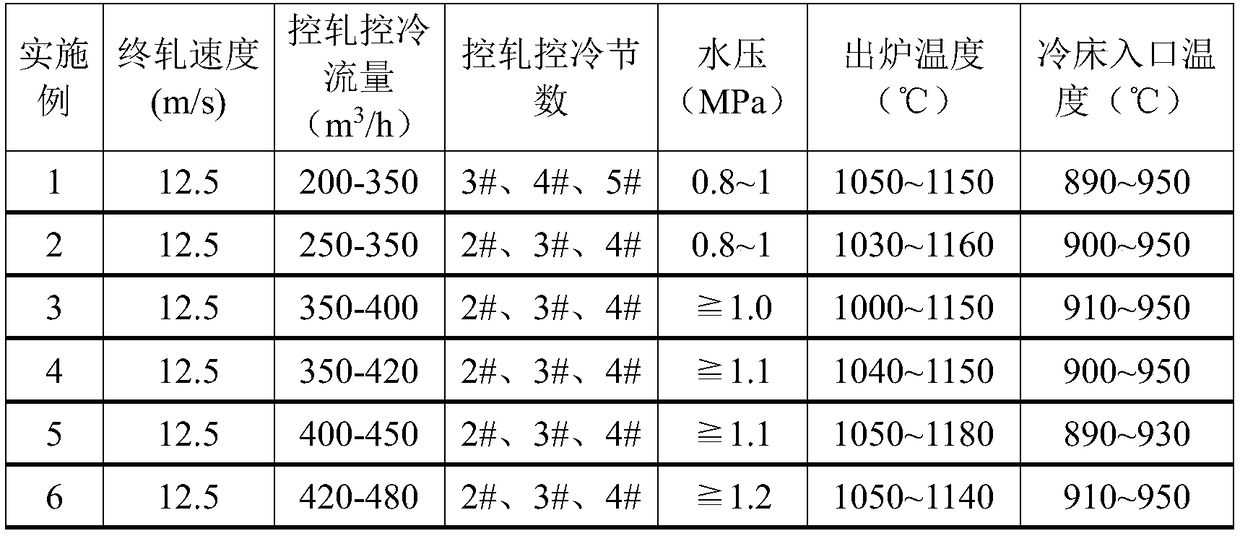

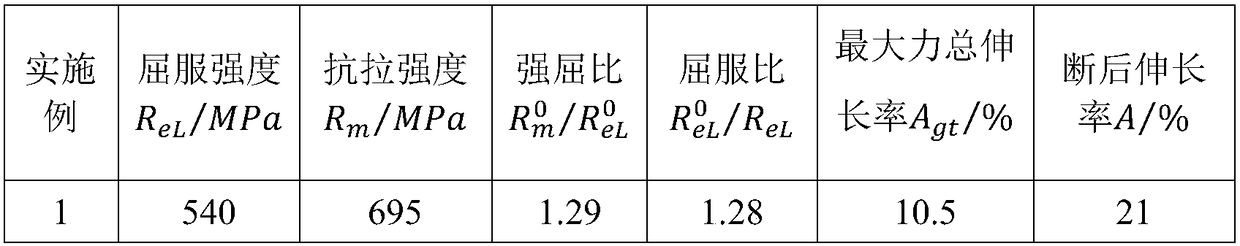

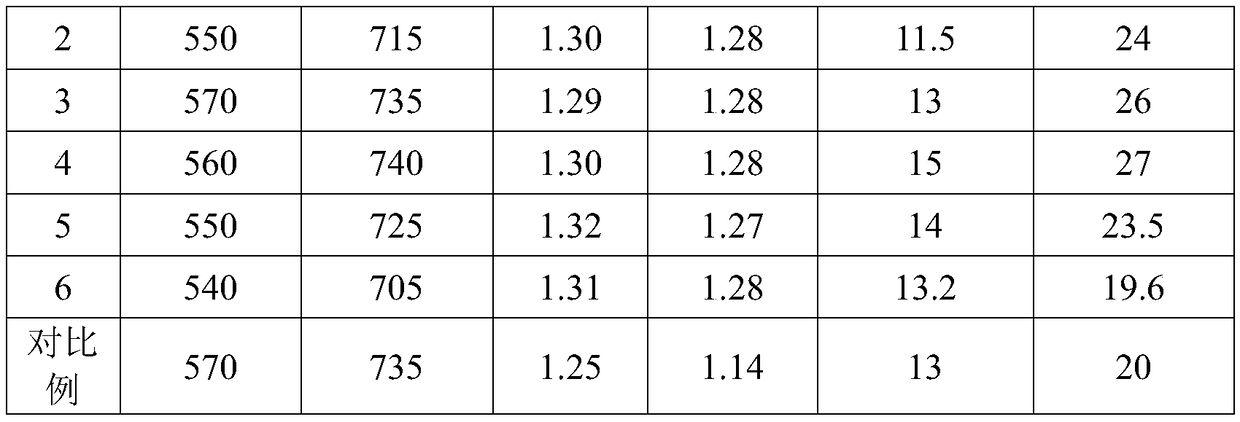

[0025] The specific implementation of the present invention will be further described below by taking the corrosion-resistant steel bar with a specification of Ф22mm as an example:

[0026] Reasonable chemical composition plays an important role in the performance of steel bars. Steel bars can not only meet the requirements of strength and plasticity, but also meet the requirements of corrosion resistance. Studies have shown that Cr, Ni, and Cu have a good effect on improving the corrosion resistance of steel bars. Through repeated experimental comparisons, the present invention finds a scientific and reasonable balance point between alloy resources and improving the corrosion resistance of steel bars, and finally develops It has good corrosion resistance and can minimize the consumption of alloy resources. The invention provides a seawater corrosion-resistant steel bar with high weather resistance and low cost, which contains the following elements by weight: C: 0.04%-0.10%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com