720MPa-grade large-thickness ship steel plate and manufacturing method thereof

A manufacturing method and large-thickness technology, which is applied in the field of low-temperature-resistant ultra-high-thickness steel plates for ships with a yield strength of 720 MPa and its manufacturing field, can solve the problems of lack of experience in polar ship design and manufacturing, and achieve improved steel purity and steel plates Low cost, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments are described below in conjunction with accompanying drawing:

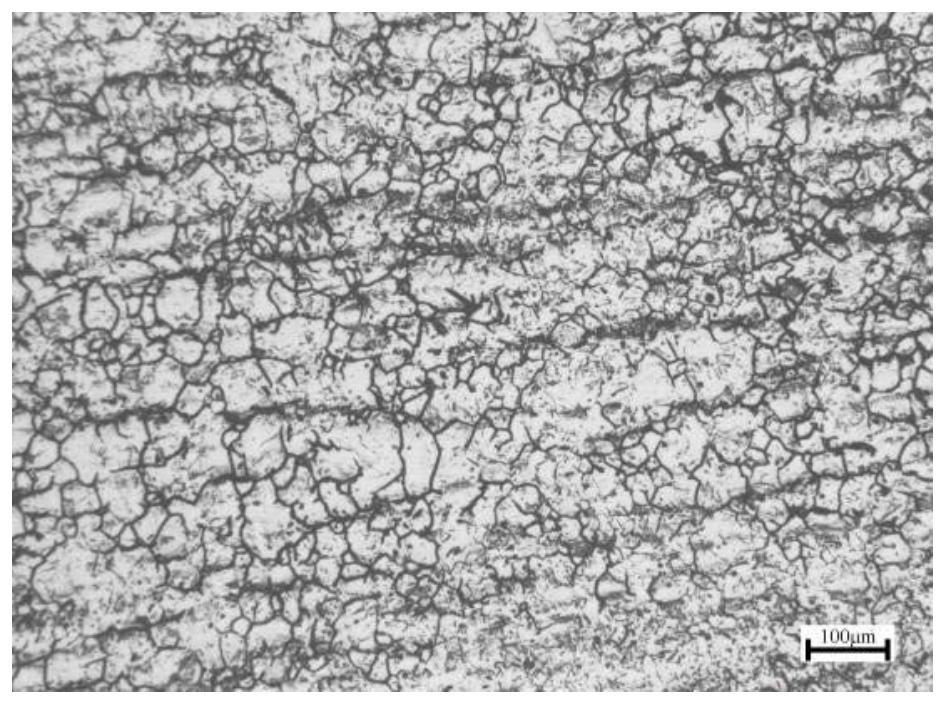

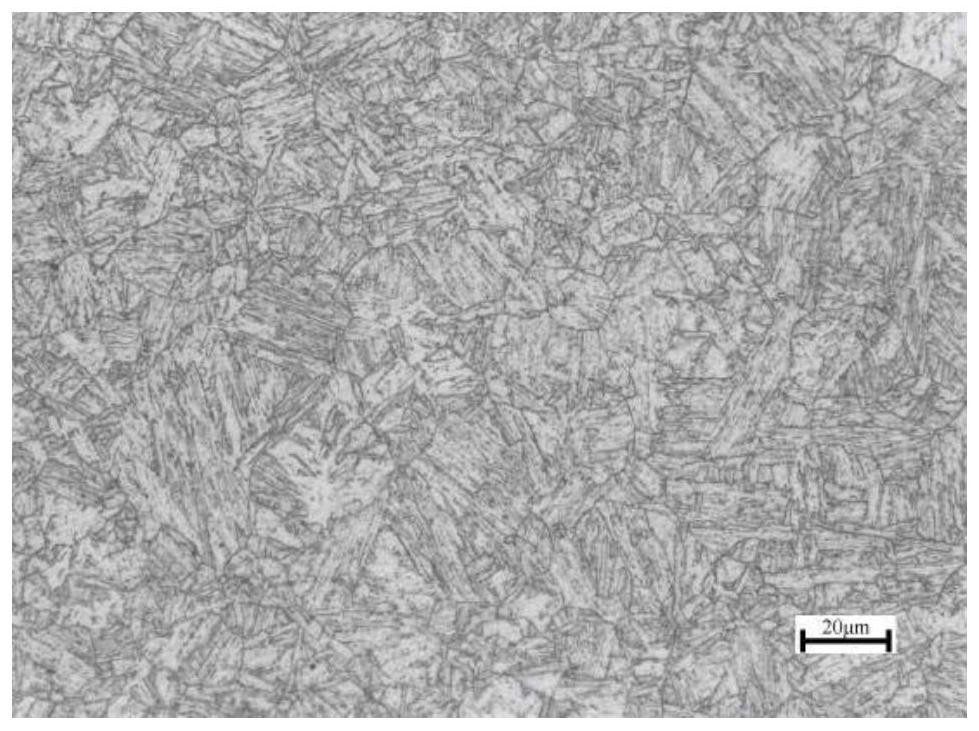

[0037]From the metallographic structure of Example 1, it can be seen that after a sub-temperature quenching + a high-temperature quenching + tempering process, the steel plate structure is basically tempered sorbite and a very small amount of bainite structure, with clear grain boundaries and crystal grains. Very small, it can be seen that, especially after two times of quenching, the grains of the steel plate are further refined, thus greatly improving the yield strength and low temperature toughness of the steel plate.

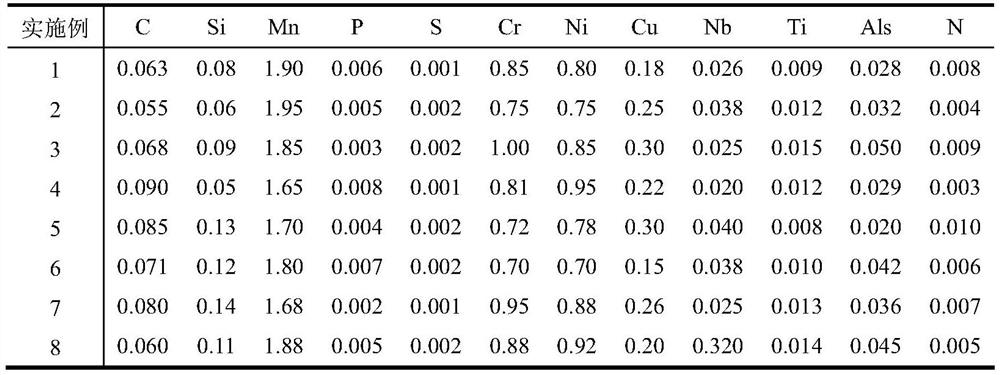

[0038] The chemical composition of the steel plate for ships with a yield strength of 720MPa grade, low temperature resistance, ultra-high strength and thickness is shown in Table 1, the technological parameters of steel billet smelting are shown in Table 2, the rolling method of the steel plate is shown in Table 3, the heat treatment process of the embodiment is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com