Patents

Literature

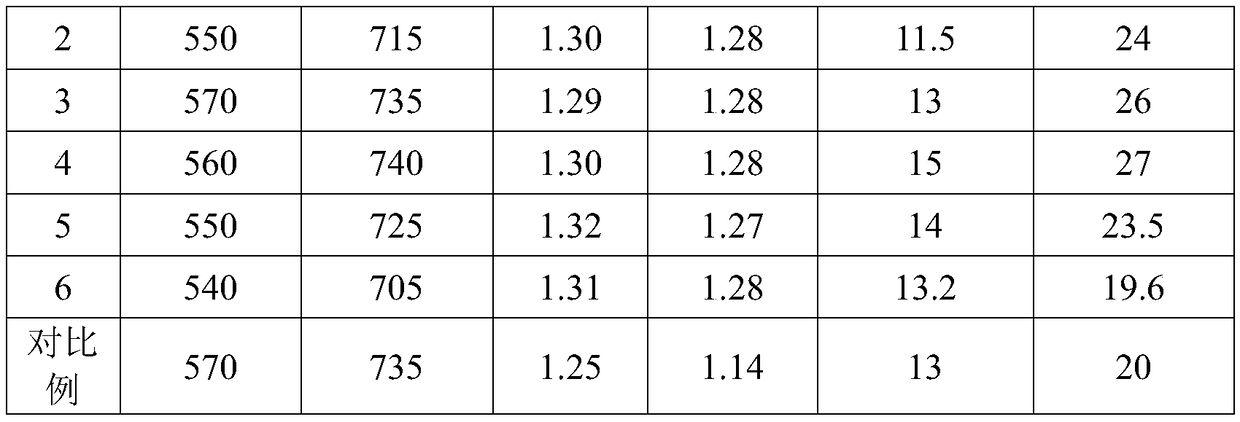

33results about How to "Avoid mechanical performance degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

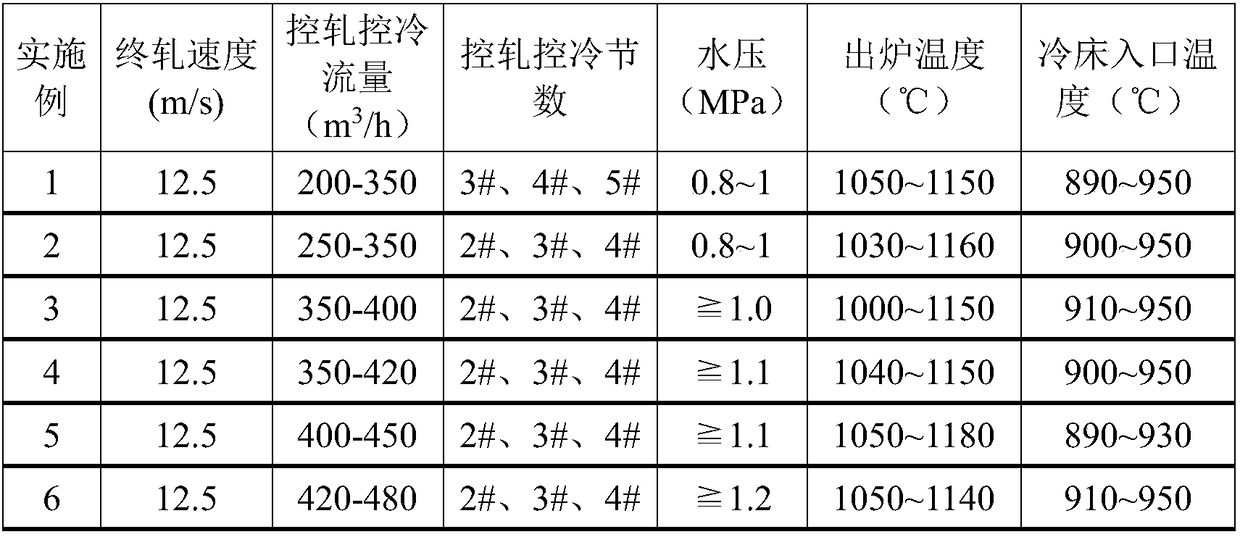

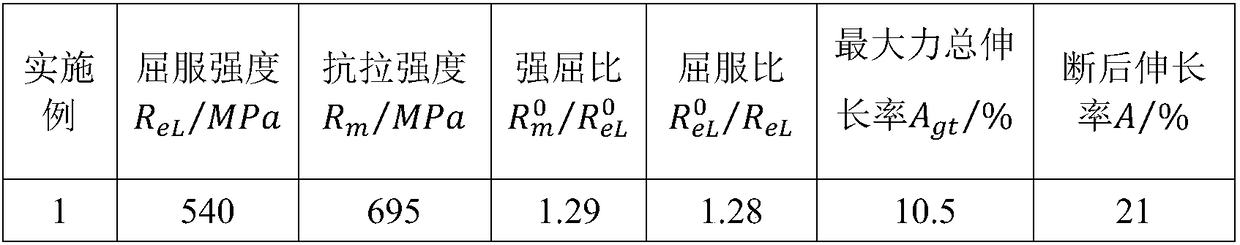

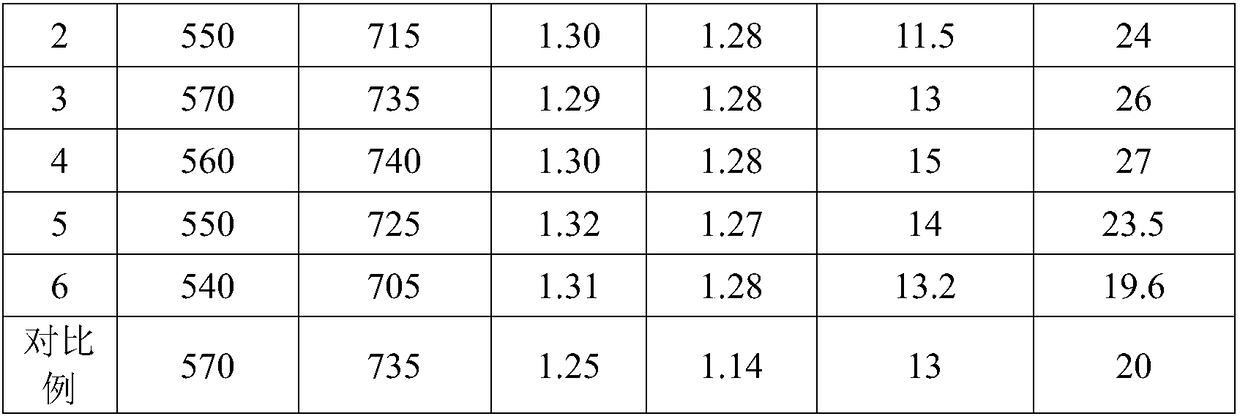

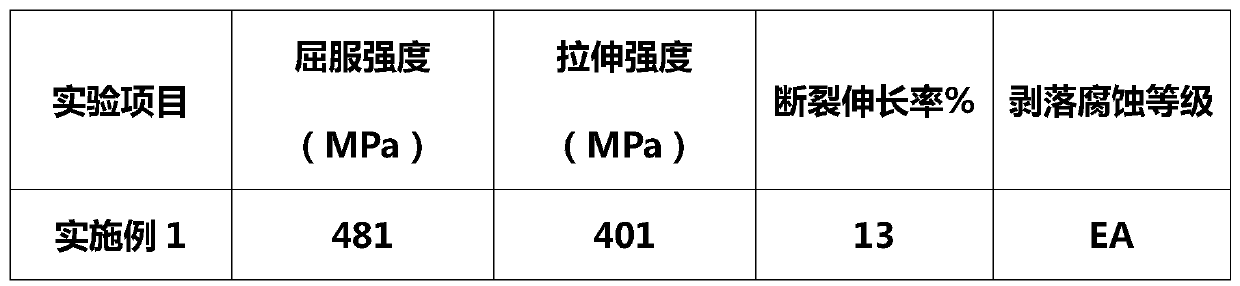

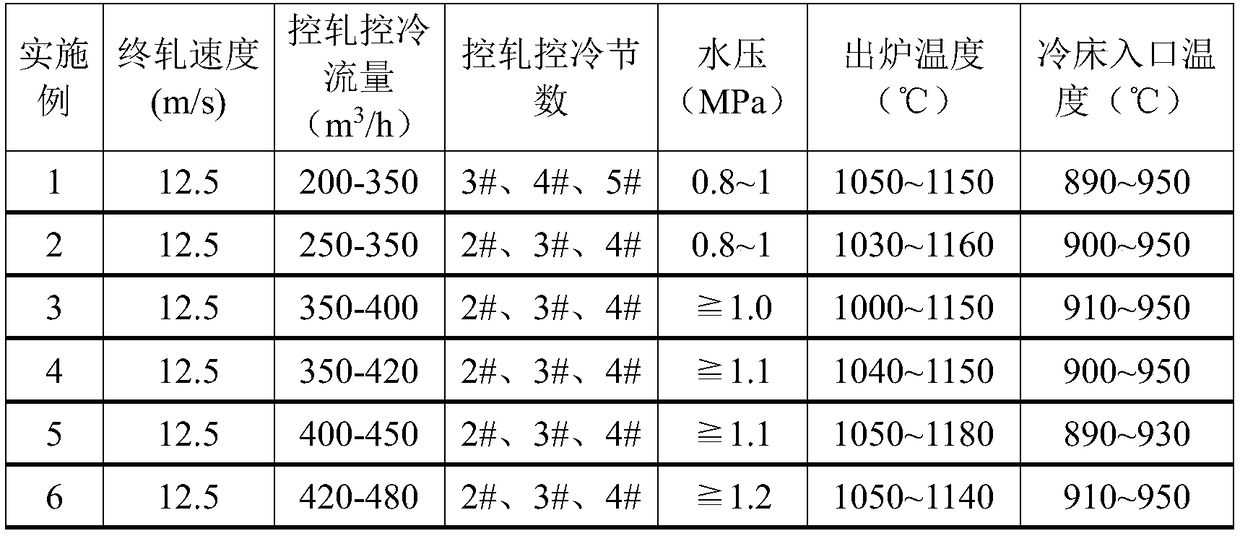

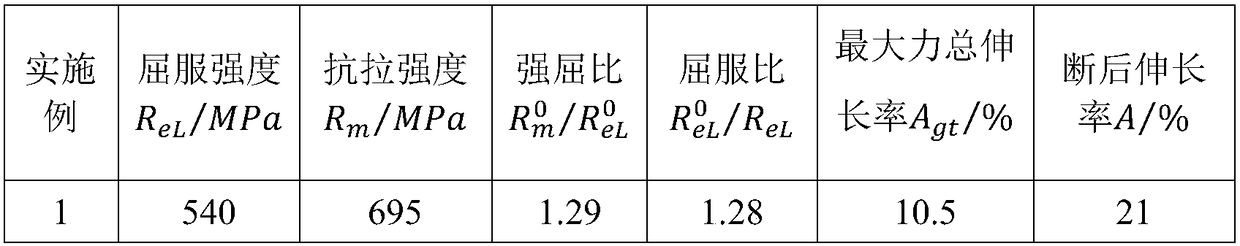

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

High-strength corrosion-resistant aluminum alloy and preparation method thereof

ActiveCN111500906AIncreases alloy ductility and corrosion resistanceImprove alloy strengthAlloy elementCorrosion resistant

The invention belongs to the field of aluminum alloy materials and discloses a high-strength corrosion-resistant aluminum alloy. The high-strength corrosion-resistant aluminum alloy comprises the following components: 1.3-1.8% of Mg, 1.5-2.0% of Si, 0.7-0.9% of Mn, 0.1-0.4% of Cu, 0.3-0.8% of Zn, 0.1-0.3% of Fe, 0.08-0.2% of Cr, 0.1-0.3% of other alloying elements and the balance Al; the other alloying elements comprise Ni, V, Ti, Zr, and a combination of rare earth elements, with a ratio being (0.2-0.4): (1.6-1.8): (0.4-0.6): (1.4-1.6): 0.2; the ratio of Zn to Fe is 3:1; and the rare earth elements comprises Gd, La, Eu, with Gd accounting for 60% or more of the total amount of the rare earth elements. The aluminum alloy of the invention improves the strength and mechanical properties by improving the material formula, and is mainly used for manufacturing some aluminum alloy parts which require corrosion resistance and certain high strength.

Owner:福建祥鑫股份有限公司

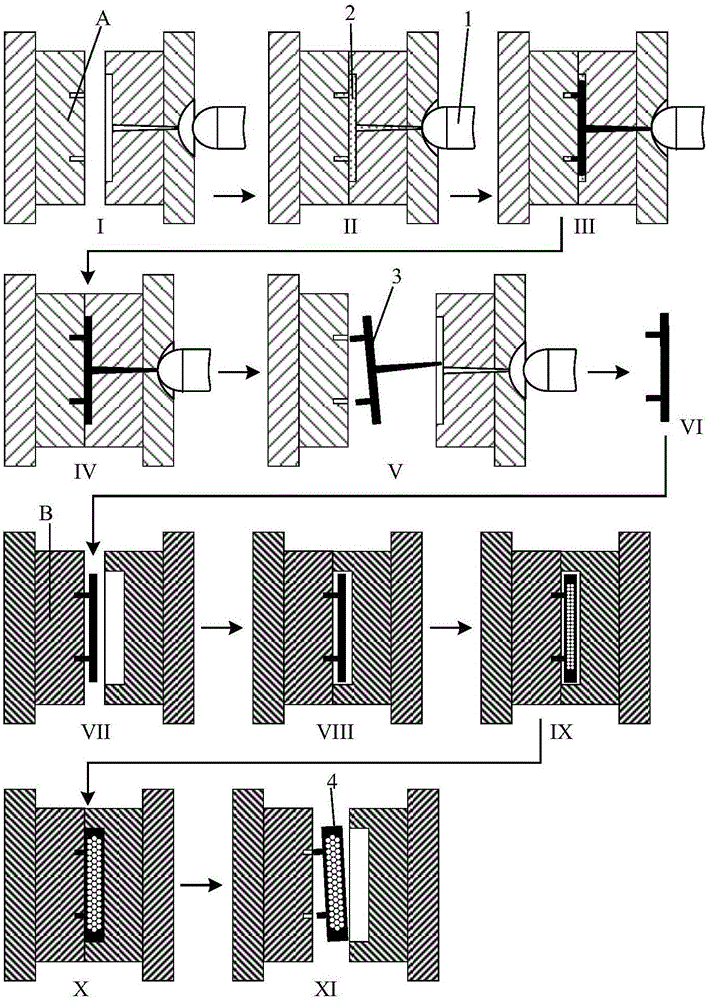

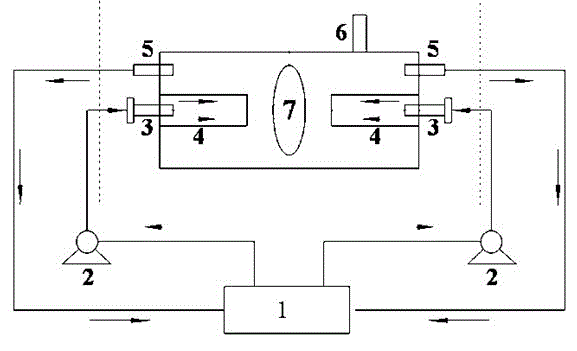

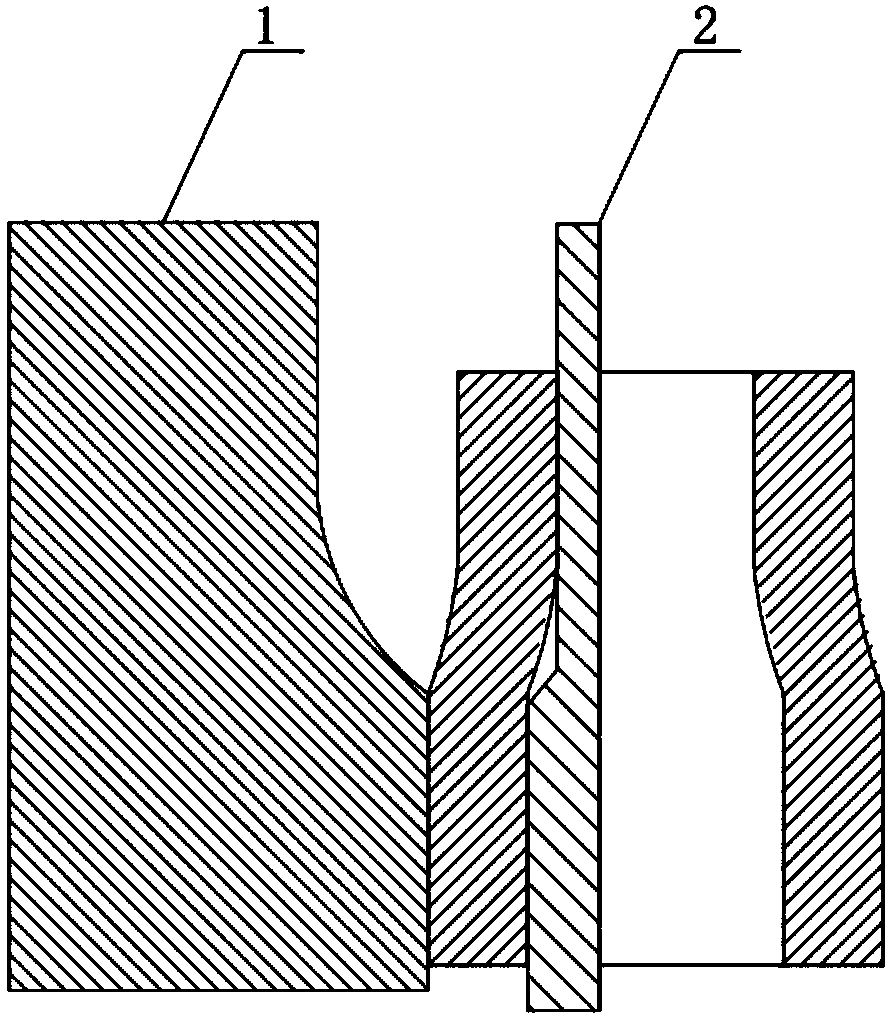

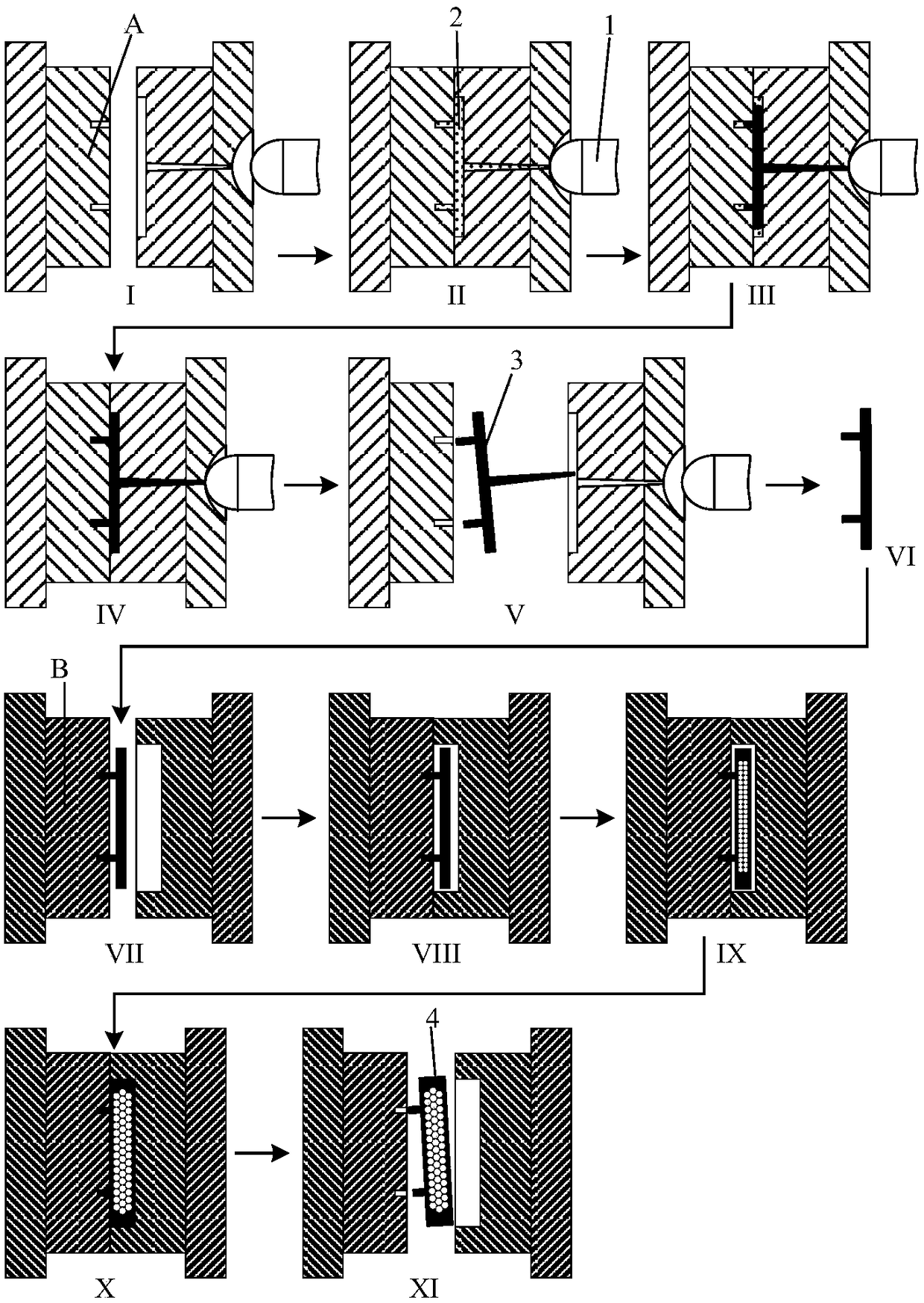

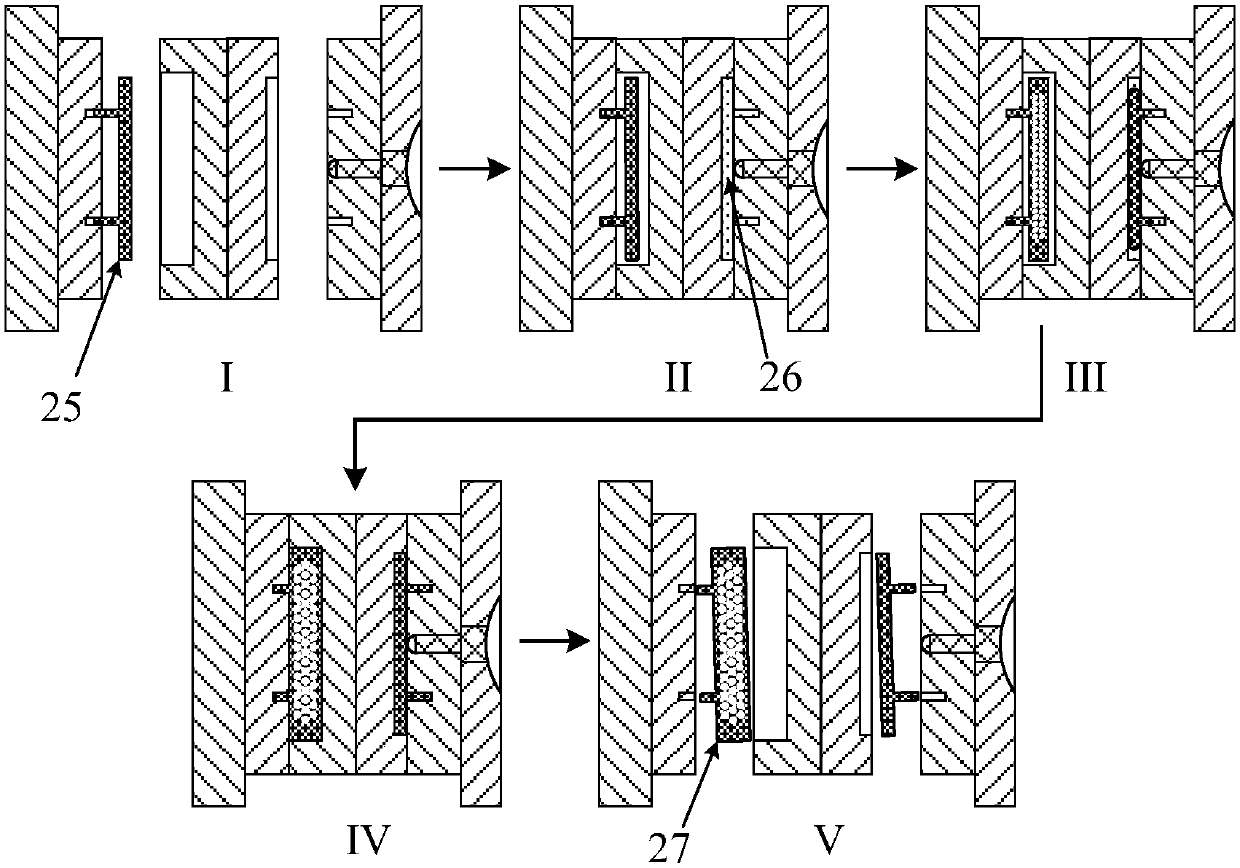

Microcellular foaming injection molding technology capable of realizing high foaming ratio and preventing surface from having foam marks

The invention discloses a microcellular foaming injection molding technology capable of realizing the high foaming ratio and preventing a surface from having foam marks. The technology comprises steps as follows: polymer melt and a foaming agent are mixed, a preformed blank is molded and transferred, heating and foaming are performed, and a final product is obtained after cooling. The preformed blank and the final product are molded in two mold cavities with different volumes. High cavity pressure, high injection pressure and high holding pressure are adopted, so that the preformed blank is prevented from foaming in the molding process. After the cooled preformed blank is fixed in a final product molding cavity, molds are closed and heated, and the inside of the preformed blank foams. Through the high-pressure injection technology of the preformed blank, the surface of the product can be free of defects such as crazing, spiral stripes, foam pits and the like, and the volume difference between the preformed blank and the final product provides space for growth of a bubble-shaped nucleus. The technology can be used for producing microcellular foaming injection molded products with good surface quality and dense inside cells.

Owner:SHANDONG UNIV

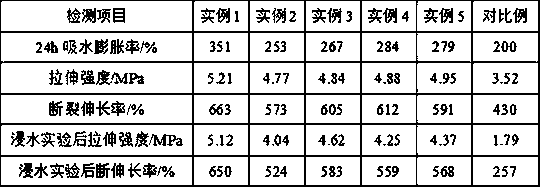

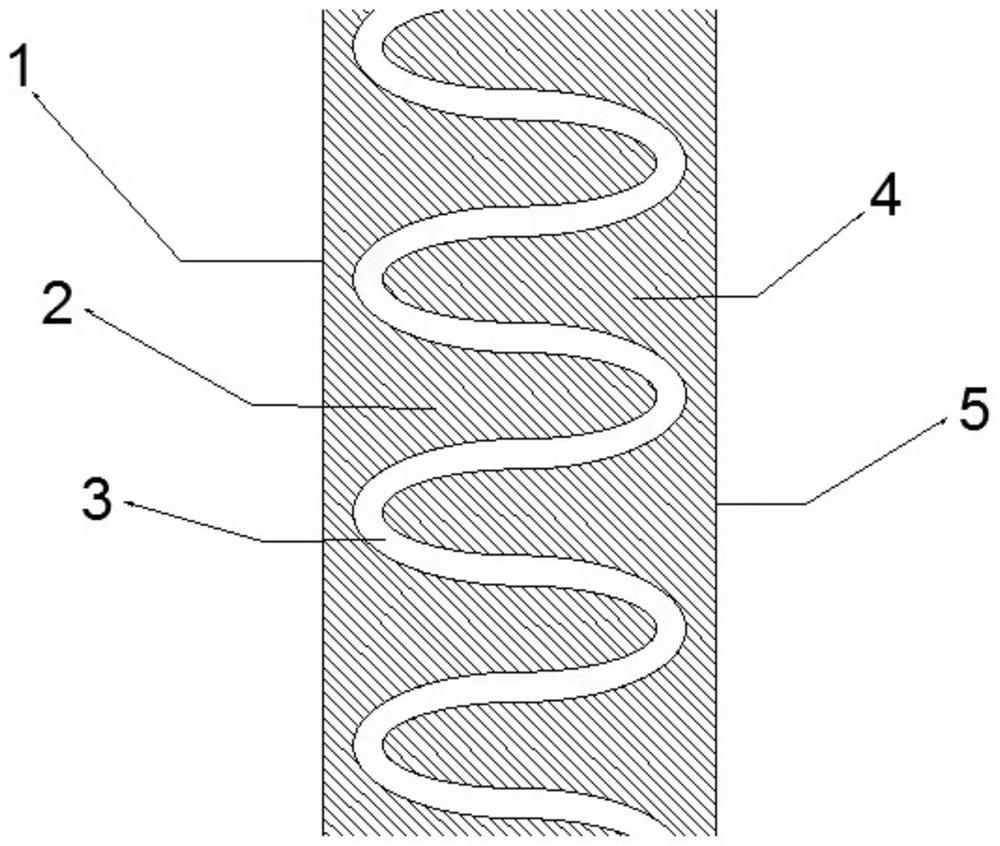

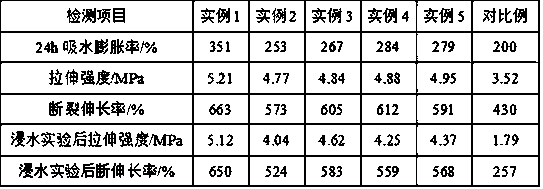

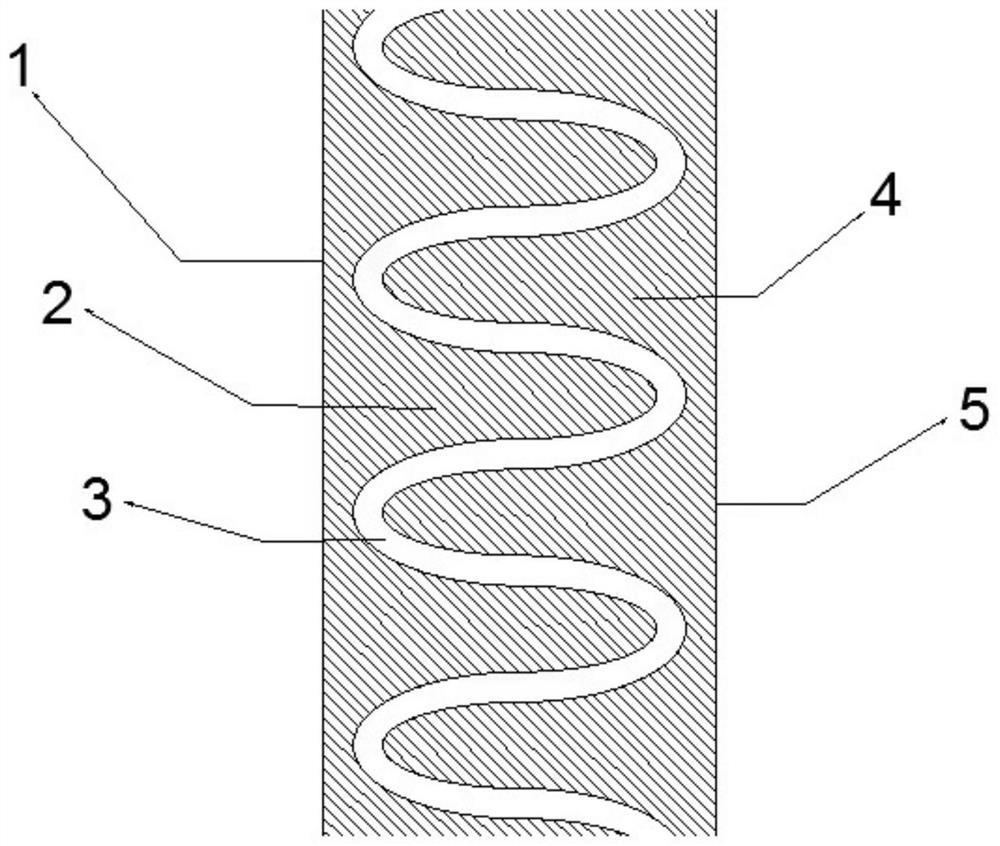

Bentonite based composite sealing rod

The invention discloses a bentonite based composite sealing rod, and belongs to the technical field of building materials. The developed bentonite based composite sealing rod comprises modified bentonite, a water absorbent resin, poly-allylamine, a rubber compound, a tackifying resin, a plasticizer and an antiager. In the preparation process, the rubber is plasticated firstly to obtain a plasticated rubber, then the plasticated rubber, the modified bentonite, the water absorbent resin, the plasticizer, the antiager, the tackifying resin and the poly-allylamine are mixed, extracted and formed to obtain the bentonite based composite sealing rod, wherein the modified bentonite is prepared by mixing and ball-milling the bentonite, isocyanate and a coupling agent.

Owner:上安实业江苏有限公司

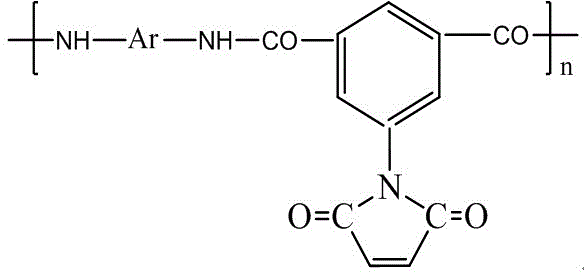

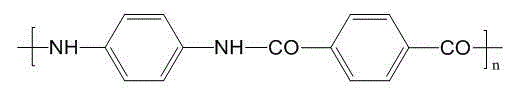

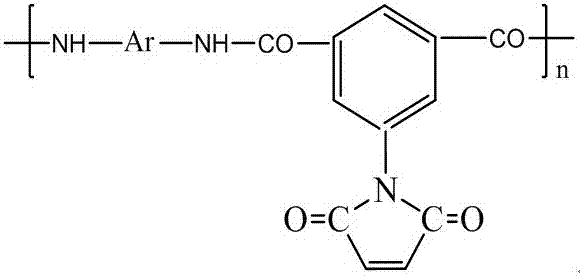

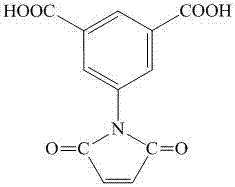

Synthesis method of wholly aromatic polyamide

The invention discloses a synthesis method of wholly aromatic polyamide. The synthesis method of the wholly aromatic polyamide comprises the following steps: (1) synthesizing a polymeric monomer 5-cis-butene imidodicarbonic diamide terephthalic acid; and (2) completely dissolving a chaotropic agent with the mass fraction of 0.5-6.0% in an organic solvent, adding 5-cis-butene imidodicarbonic diamide isophthalic acid synthesized in the step (1) and aromatic diamine in an equal molar ratio, cooling, precipitating, washing and drying, thus obtaining the wholly aromatic polyamide product. The synthesis method of the wholly aromatic polyamide has the advantages that the wholly aromatic polyamide synthesized through homopolymerization can be used for effectively improving solubility of a polymer in an organic solvent, so that the aromatic polyamide can be conveniently dissolved into the organic solvent for carrying out a spinning processing technique and the like; meanwhile, the prepared wholly aromatic polyamide is regular in a molecular chain and high in rigidity, so that mechanical properties can be not reduced, and the application field of the wholly aromatic polyamide is expanded.

Owner:CHINA PETROLEUM & CHEM CORP +1

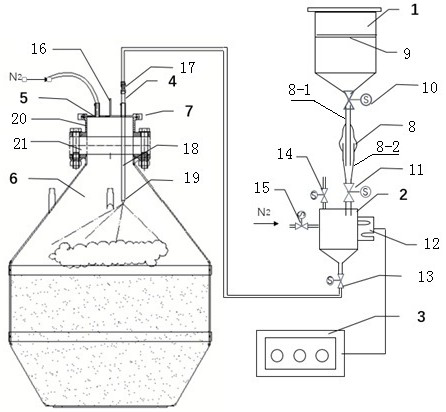

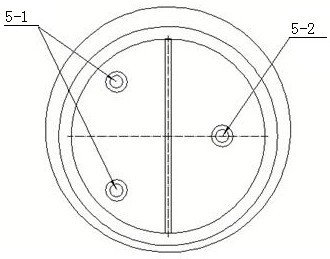

Atomization adding device and atomization adding method for neodymium iron boron magnetic powder mixture additive

PendingCN111940748AWon't clogResidue reductionTransportation and packagingMetal-working apparatusMetallurgyControl system

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

High-strength weldable aluminum alloy and preparation method thereof

The invention belongs to the field of an aluminum alloy material and discloses high-strength weldable aluminum alloy. The high-strength weldable aluminum alloy comprises the following components: 0.4to 1.2 percent of Mg, 0.7 to 1.4 percent of Si, 0.2 to 0.7 percent of Mn, 0.05 to 0.2 percent of Cu, 0.1 to 0.5 percent of Zn, 0.4 to 0.6 percent of Fe, 0.05 to 0.15 percent of Cr, 0.1 to 0.3 percentof other alloy element and the balance of Al, wherein other alloy element comprises combination of Ni, V, Ti, Zr and rare earth element with the ratio of (1.2-1.4):(0.6-0.8):(2.4-2.6):(0.4-0.6):0.2; and the rare earth element comprises Ce, La and Er, and Ce account for more than 60 percent of the total amount of the rare earth element. Through improvement of the original formula, the aluminum alloy improves strength and mechanical property and can serve as aluminum alloy parts, such as an end plate and a tray, in a power battery of a new energy automobile.

Owner:福建祥鑫股份有限公司

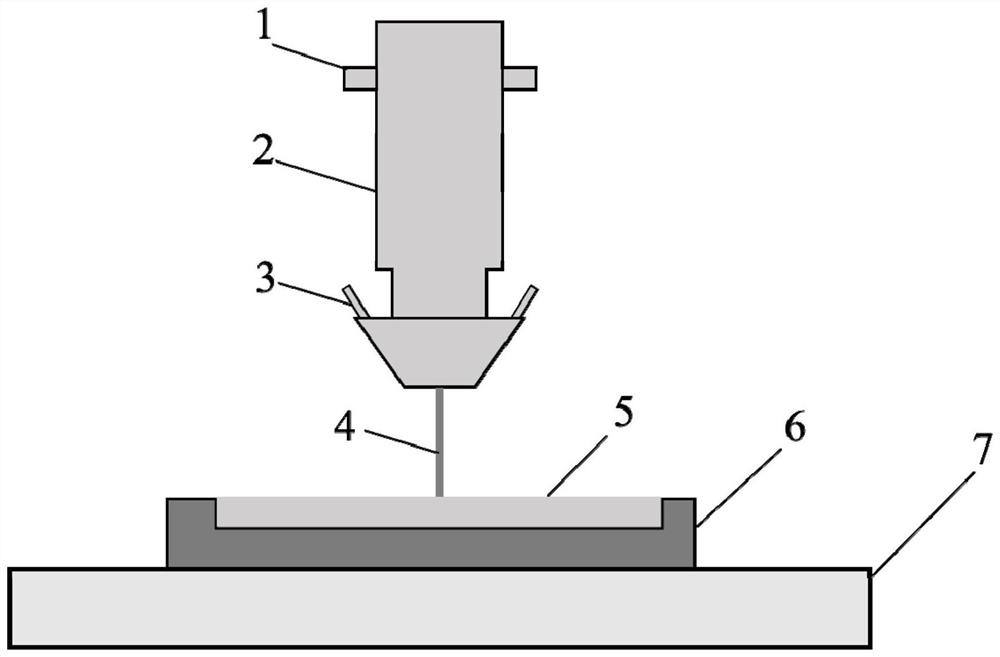

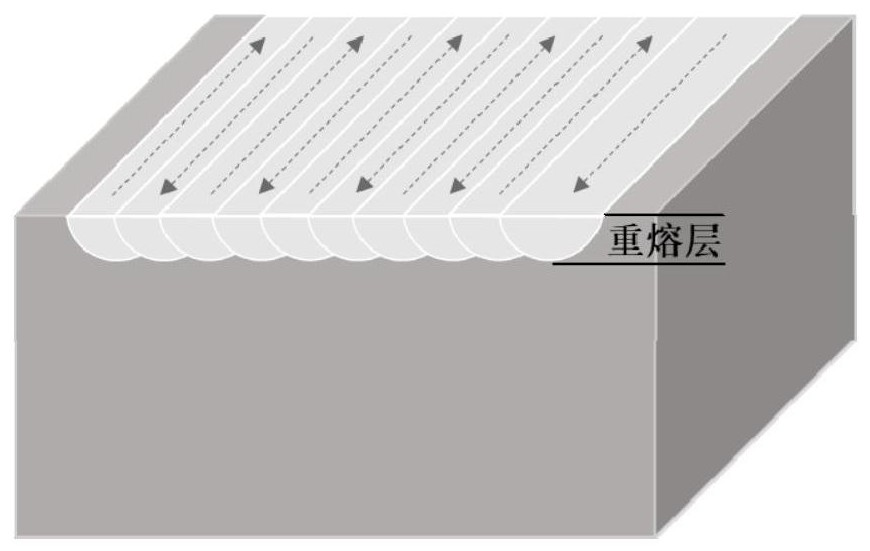

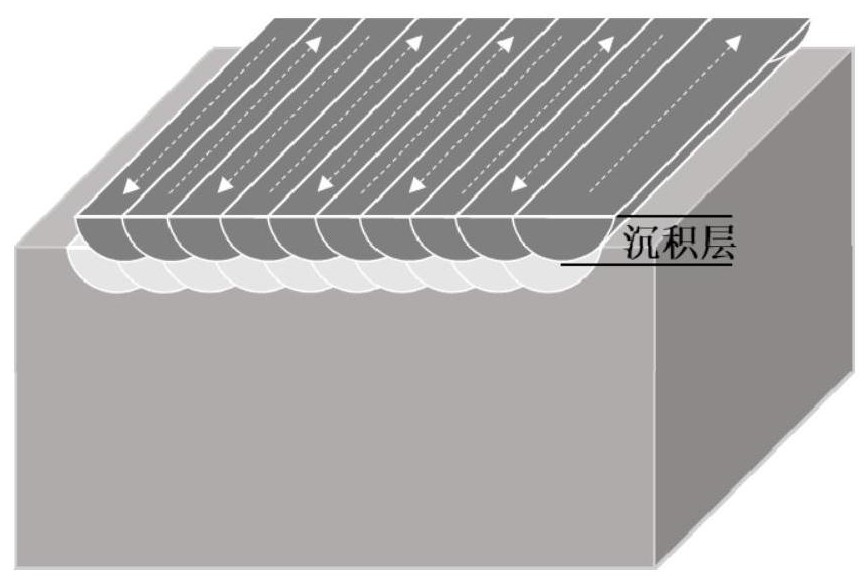

Method for controlling directional growth of alloy grains in laser additive manufacturing process

PendingCN114505496AReduced nucleationPromote growthAdditive manufacturing apparatusIncreasing energy efficiencySuperalloyLaser additive manufacturing

The invention relates to a method for controlling directional growth of alloy grains in a laser additive manufacturing process. A method for controlling directional growth of alloy grains in the laser additive manufacturing process comprises the steps that a base material is selected, laser remelting treatment is conducted on the surface of the base material, and then laser additive manufacturing is conducted on the remelted surface. By means of the method, crystal grains can grow in an oriented mode, the mixed crystal generation probability is reduced, the bad influence of a transverse crystal boundary on high-temperature alloy is reduced, a prepared component structure can grow in an epitaxial mode according to the original crystal grain orientation of a remelting layer, and the better mechanical property is achieved in the low-temperature single-stress and high-temperature environment.

Owner:BEIHANG UNIV

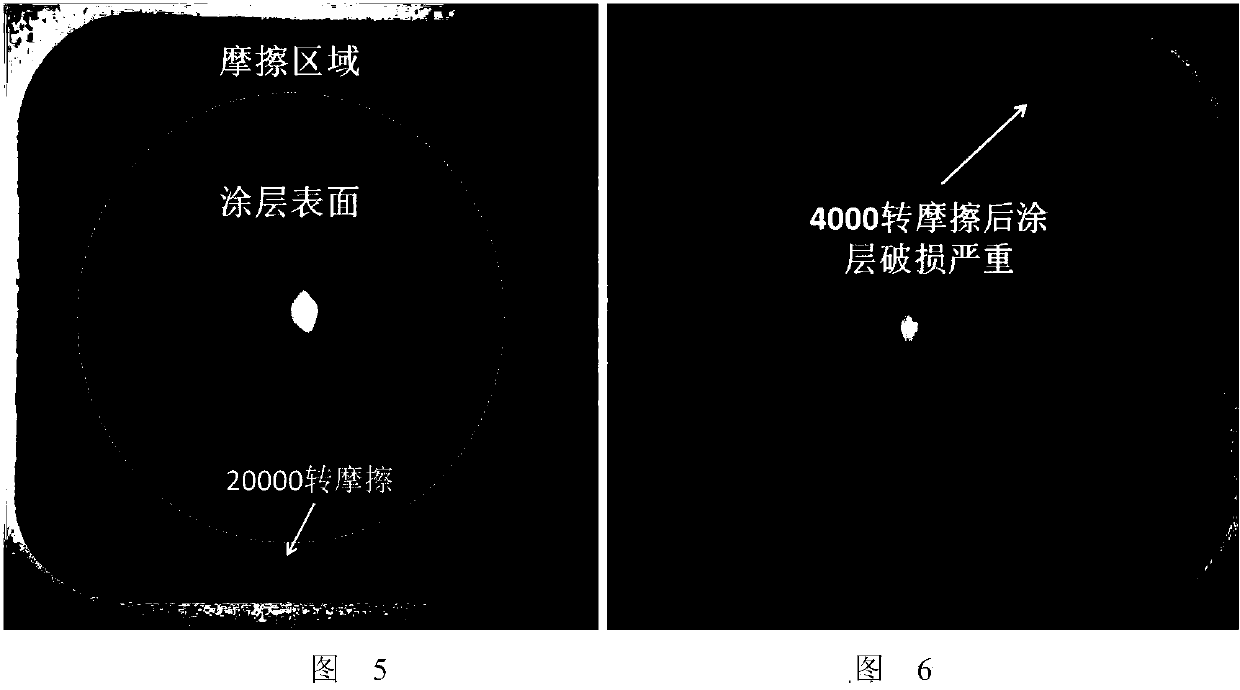

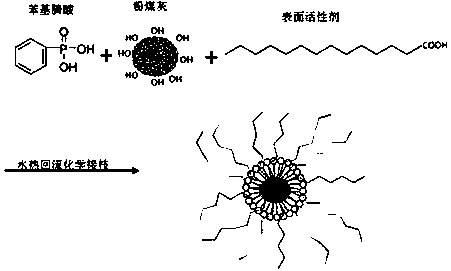

Novel anti-corrosion coating and preparation method thereof

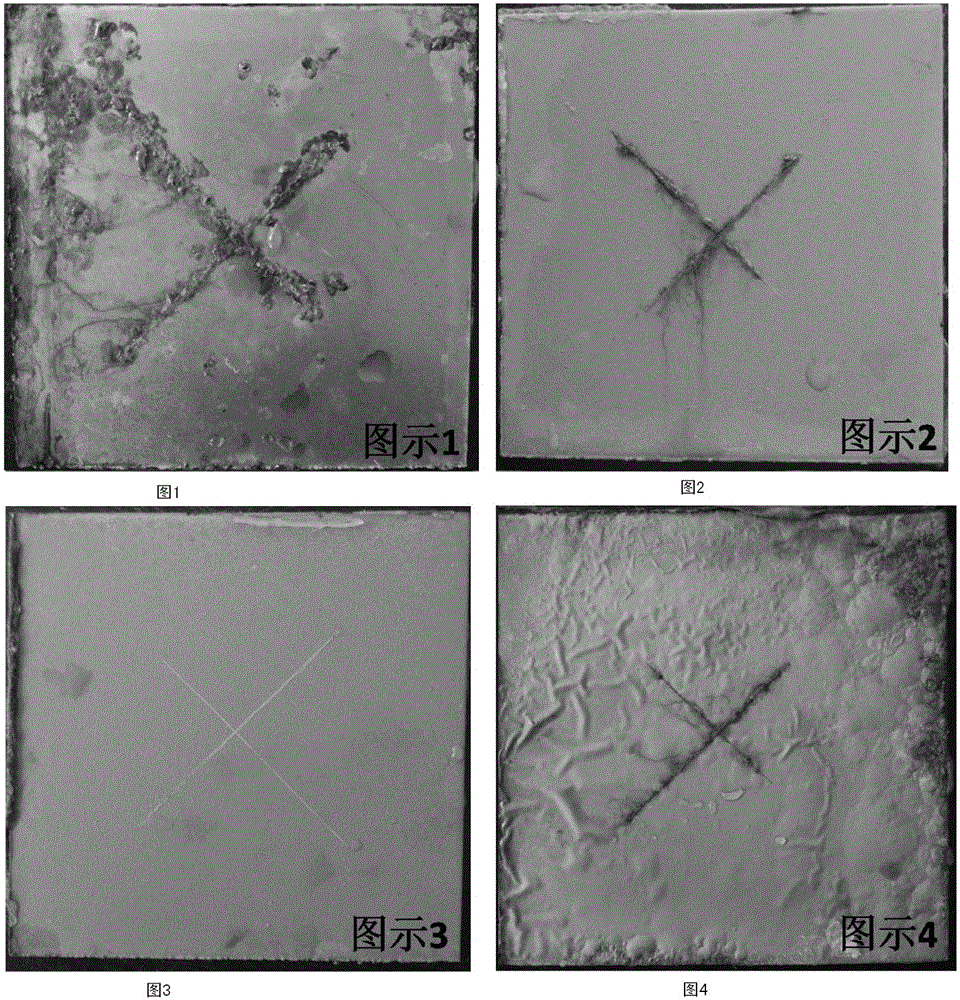

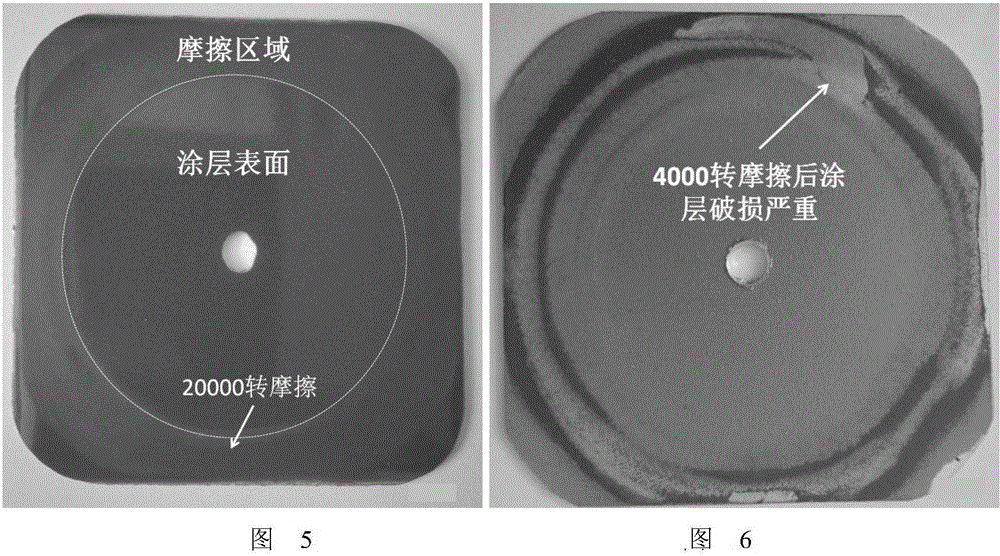

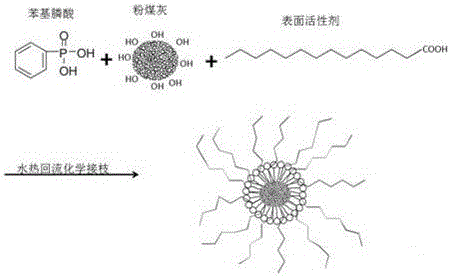

ActiveCN105838186AImprove wear resistanceImprove anti-corrosion performancePretreated surfacesAnti-corrosive paintsPulverised fuel ashCorrosion inhibitor

The invention discloses a novel anti-corrosion coating and a preparation method thereof and solves the problem of reduction of mechanical performances of the coating since a corrosion inhibitor on a fly ash anti-corrosion coating in the prior art is difficult to disperse. In the invention, through a reflux method, phenyl phosphonic acid and a surfactant are grafted on surface of fly ash, wherein the phenyl phosphonic acid and the surfactant are hydrolyzed during a heating process and are connected to a part of hydroxyl groups on the surface of the fly ash. The grafted fly ash finally turns into sea urchin-like granules. The phenyl phosphonic acid increases dispersion of fly ash particles in resin and combination area of the fly ash particles with resin, thereby greatly improving anti-wear performance of coating. The phenyl phosphonic acid and the surfactant can enable the corrosion inhibitor to be dispersed in nano-micro pores in the fly ash more uniformly, thereby achieving the corrosion inhibition effect and improving the anti-corrosion performance of the coating.

Owner:NORTHEAST GASOLINEEUM UNIV

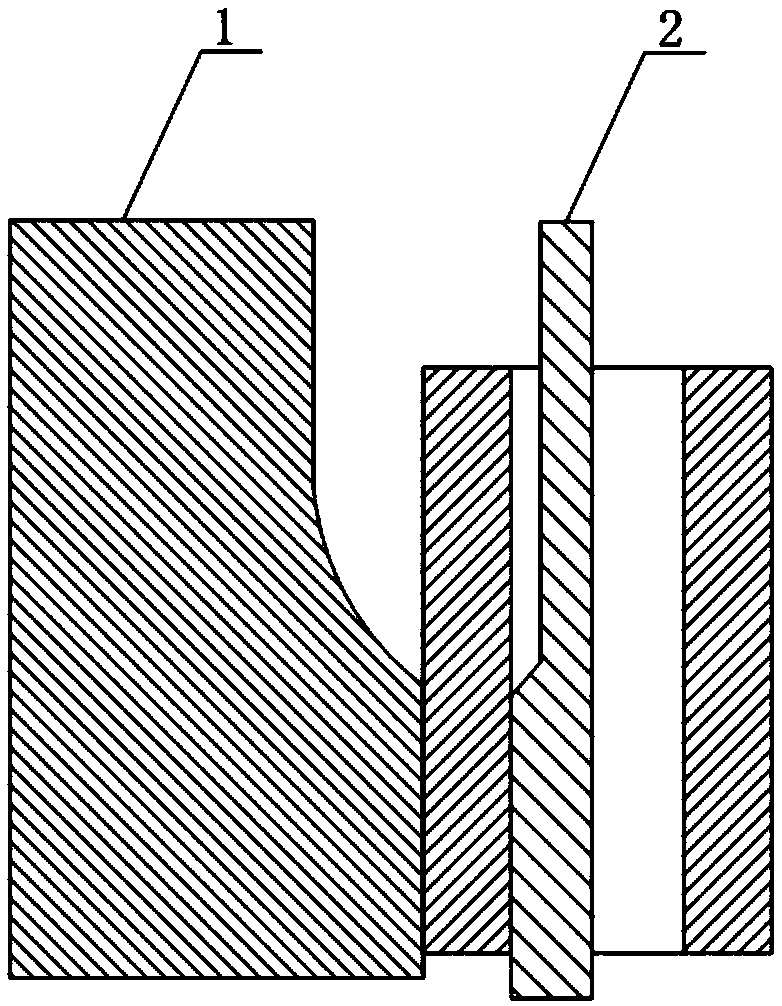

Segmentally rolling method for large-scale high-temperature alloy high-cylindrical forging piece

ActiveCN108746440AImprove mechanical propertiesQuality improvementMetal rollingAlloyMechanical property

The invention relates to a segmentally rolling method for a large-scale high-temperature alloy high-cylindrical forging piece. The segmentally rolling method for the large-scale high-temperature alloyhigh-cylindrical forging piece comprises the steps of after heating, forging, chambering a blank and pulling a central spindle, firstly adopting a segmental irregular mold for segmentally and locallyrolling the annular blank, and then adopting a direct-wall mold for integrally rolling the segmentally and locally rolled annular piece, wherein the segmental irregular mold comprises an irregular main roller and an irregular core roller, the roller surfaces of the irregular main roller and the irregular core roller locally contact a wall surface of the annular blank, the direct-wall mold comprises a direct-wall main roller and a direct-wall core roller, the roller surfaces of the direct-wall main roller and the direct-wall core roller partially contact the blank during the rolling process and integrally contact the blank after rolling; and coating a heat-insulation coating on the roller part of the segmentally rolled annular piece, so that the integral mechanical property of the annularpiece during a follow-up rolling process is ensured. Through the method, the utilization ratio of the material and the mechanical property and the quality of the material can be improved, and meanwhile, the requirement for the rolling force of the equipment is lowered.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Method for improving mechanical property of carbon fiber-reinforced aluminum matrix composite

ActiveCN112981282AImprove bending strengthImprove mechanical propertiesCarbon fibersAluminium matrix

The invention discloses a method for improving the mechanical property of a carbon fiber-reinforced aluminum matrix composite. The invention aims to solve the problem that an interface product Al4C3 is easily generated on an interface of an aluminum alloy and carbon fibers during preparation of an existing carbon fiber-reinforced aluminum matrix composite. The method comprises the following steps of: weighing an aluminum-cerium intermediate alloy and the aluminum alloy as raw materials, heating and melting the aluminum alloy at high temperature, adding the aluminum-cerium intermediate alloy, and stirring to obtain a cerium-containing aluminum alloy melt; and carrying out pressure infiltration and heat treatment. The thermodynamic principle is utilized, elements easy to segregate are added and segregated and separated out on the grain boundary, so that the interface contact state of the carbon fibers and an aluminum matrix is improved, the surface energy of the grain boundary can be reduced, and interface reaction is reduced. Therefore, the interface reaction of the carbon fibers and the aluminum matrix is inhibited, damage to the carbon fibers is reduced, and the mechanical property of the composite is improved. The method is suitable for preparing the carbon fiber-reinforced aluminum matrix composite.

Owner:HARBIN INST OF TECH

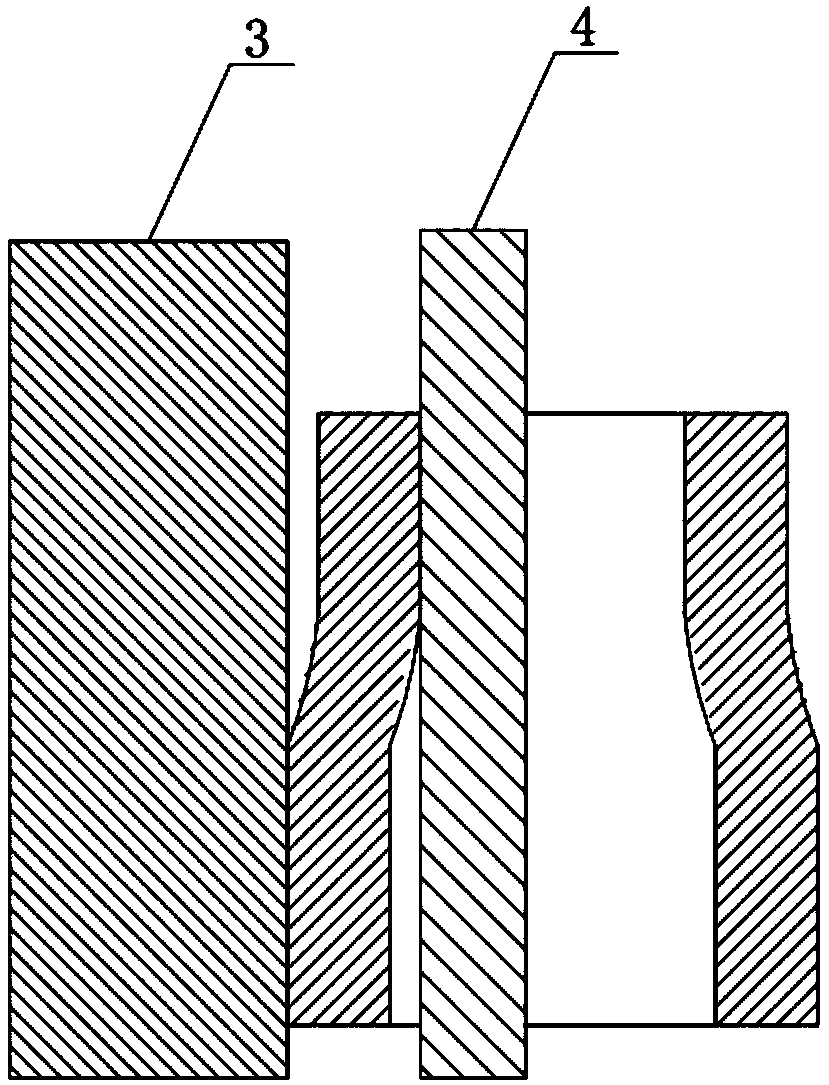

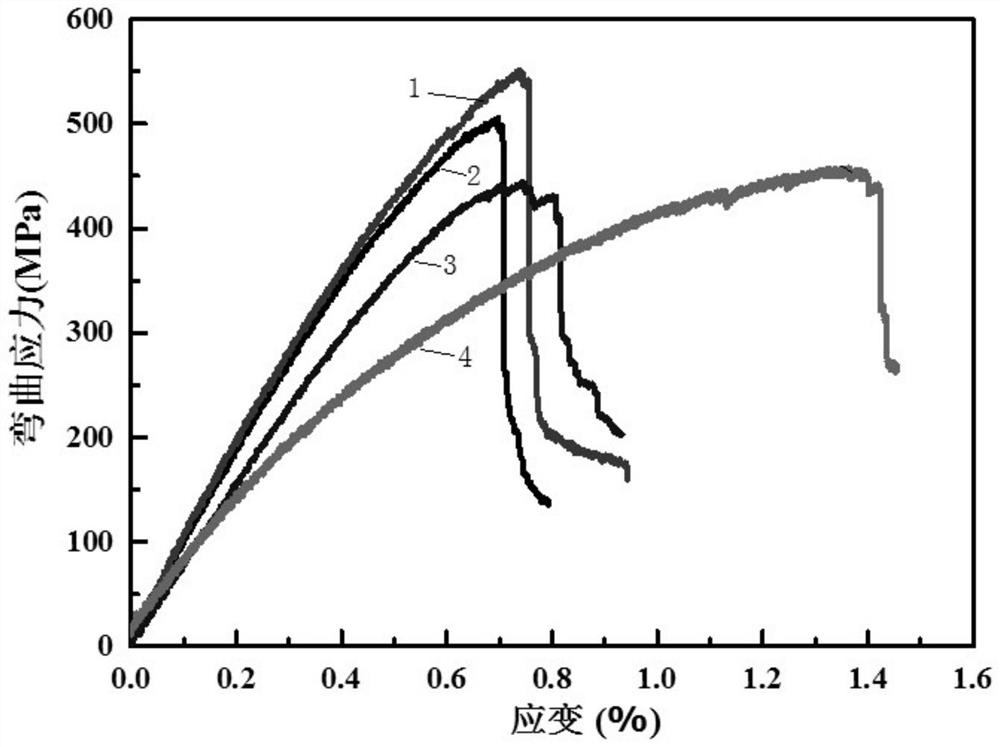

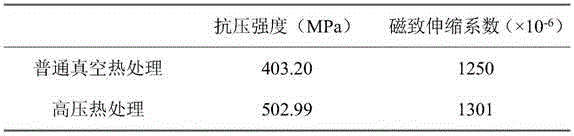

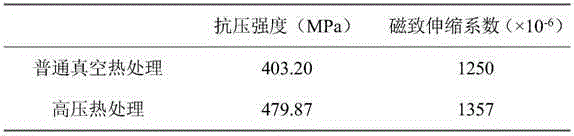

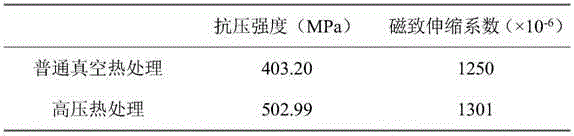

Preparation method for improving mechanical property of giant magnetostrictive material

The invention relates to a preparation method for improving the mechanical property of a giant magnetostrictive material, and belongs to the field of magnetic materials. The preparation method concretely comprises the following steps of preparing a giant magnetostrictive material terbium-dysprosium-iron alloy with specific orientation through blending, vacuum smelting and directional solidification; placing a sample to be treated into a heat treating furnace, vacuumizing to 0.01 Pa, and then starting heating; continuously vacuumizing in a temperature increasing process; after the temperature inside the heat treating furnace is increased to 800-1200 DEG C, stopping vacuumization; introducing high-purity argon to increase the pressure inside the heat treating furnace to 1-20 MPa, and preserving the heat for 30-180 minutes; after heat preservation is finished, stopping heating, and after the sample is cooled, taking out. According to the invention, the growth of an RFe2 phase contained in the terbium-dysprosium-iron alloy can be inhibited through high-pressure heat treatment; the holes and microcracks can be decreased by regulating the diffusion and separation of a rare earth-rich phase; the coalescence of the microcracks of the material is promoted, so that the mechanical property of the giant magnetostrictive material can be improved, the waste, which is caused due to poor mechanical property, of the material is reduced, and the requirement for usage under the condition of more working conditions is met. The preparation method disclosed by the invention is easy to operate and suitable for industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

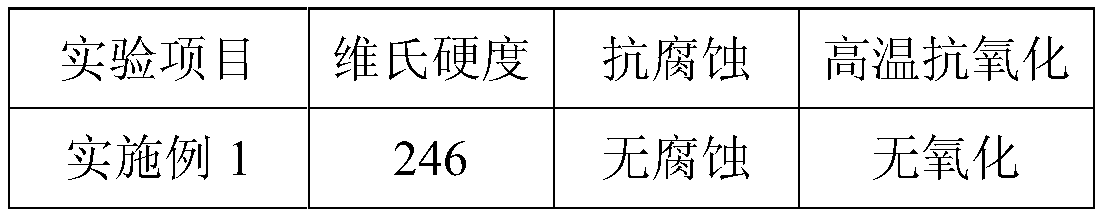

Stainless steel for medical instruments and preparation method thereof

The invention discloses stainless steel for medical instruments and a preparation method thereof. The stainless steel for the medical instruments comprises the following components of, in percentage by weight, 0.01%-0.07% of C, 0.02%-0.06% of Mn, 16%-18% of Cr, 6%-8% of Ni, 0.4%-0.8% of Mo, 0.03%-0.05% of V, 0.06%-0.1% of Nb, 0.8%-1.2% of Al, 0.01%-0.02% of B+S+F, 0.14%-0.36% of Ag, 0.14%-0.36% ofCu, the content of Sn is equal to the sum of the content of Cu and Ag, 0.01%-0.03% of silicones, 0.002%-0.004% of nanometer silicate fiber, and the balance of Fe. According to the stainless steel forthe medical instruments and the preparation method thereof, firstly, carrying out C, B and Fe alloying, S, C and Fe alloying, and Cu, Sn and Ag alloying on stainless steel for the medical instruments, and then obtaining the stainless steel through adding other components to carry out melt mechanical machining. The stainless steel for medical instruments and the preparation method thereof disclosed by the invention have the advantages that the hardness, the corrosion resistance and the high-temperature oxidation resistance of the medical instrument materials are improved.

Owner:长沙凯泽工程设计有限公司

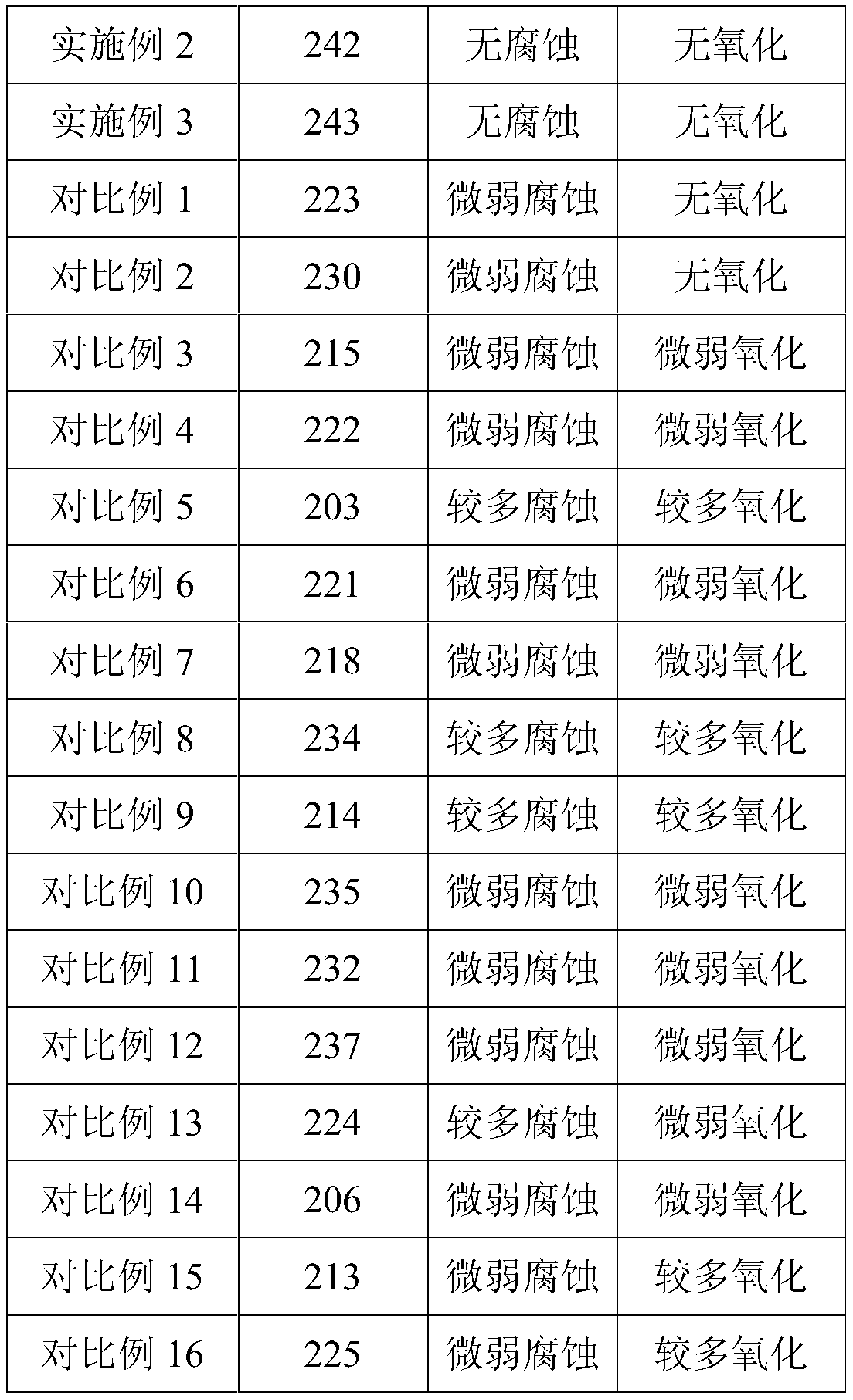

HDPE (high-density polyethylene) pipe and preparation method thereof

InactiveCN108047539AIncreased tensile strength and elongation at breakAvoid mechanical performance degradationProduct processingDibutyl tin dilaurate

The invention discloses a HDPE (high-density polyethylene) pipe and a preparation method thereof. The HDPE pipe comprises modified nano-calcium carbonate, HDPE, nano-calcium carbonate, p-hydroxybenzoic acid, organic silane modified linear low-density polyethylene, dibutyltin dilaurate and lubricants. The weight ratio of the p-hydroxybenzoic acid, the organic silane modified linear low-density polyethylene to the dibutyltin dilaurate is (5-15):(5-15):(0.1-1), and the HDPE pipe is prepared by the steps of raw material preparation, primary blank preparation, finished product processing and the like. Compared with the prior art, the HDPE pipe has the advantage that performances such as the tensile strength and the breaking elongation of the pipe are further improved.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

A kind of preparation method of high temperature resistant reinforced toughened alumina fiber reinforced alumina matrix composite material

ActiveCN112479691BHigh strengthImprove high temperature resistanceCeramicwareOXALIC ACID DIHYDRATENanowire

The invention discloses a method for preparing a high-temperature-resistant reinforced and toughened Ox / Ox composite material, and relates to the technical field of ceramic-based composite materials. The present invention first adopts the mixed solution of ammonium dichromate and anhydrous oxalic acid to pre-treat the alumina fiber fabric by impregnation-heat treatment to obtain the surface-coated alumina fiber, and then put it into CVI to prepare pyrolytic carbon coating or BN coating. The nanowire coating is obtained by electrophoretic deposition on the coating, and then the alumina ceramic slurry is coated on the surface of the alumina fiber fabric with the nanowire coating for hot pressing and sintering to obtain a high-performance Ox / Ox composites. The invention provides a method for preparing a high-temperature-resistant reinforced and toughened Ox / Ox composite material, which obtains a high-density matrix and a porous nano-oxide coating, so that a weak interface is formed between the alumina fiber and the alumina matrix, thereby obtaining A high-strength, high-toughness, high-temperature-resistant alumina fiber-reinforced alumina matrix composite was developed.

Owner:CENT SOUTH UNIV

Thermoplastic fiber metal laminate and preparation method thereof

InactiveCN108202513AEvenly dispersedImprove bindingLaminationLamination apparatusFiber bundleFiber metal laminate

The invention discloses a thermoplastic fiber metal laminate and a preparation method thereof. The preparation method comprises S1, providing a thermoplastic blended woven fabric, S2, overlaying the thermoplastic blended woven fabric and a metal material layer to obtain a laminated plate, and S3, hot-pressing the laminated plate and carrying out cooling molding to obtain the thermoplastic fiber metal laminate. The thermoplastic blended woven fabric is woven from a fiber bundle. The fiber bundle comprises a thermoplastic fiber material and a reinforcing fiber material. The preparation method issimple and improves the interlayer bonding force and mechanical properties of the thermoplastic fiber metal laminate.

Owner:BYD CO LTD

A kind of synthetic method of fully aromatic polyamide

The invention discloses a method for synthesizing a wholly aromatic polyamide, which comprises the following contents: (1) synthesizing a polymerization monomer 5-maleimide terephthalic acid; (2) converting the mass fraction to 0.5~ 6.0% of the solubilizer is completely dissolved in the organic solvent, and the 5-maleimide-based isophthalic acid and aromatic diamine synthesized in equimolar ratio step (1) are added for homopolymerization reaction, after cooling , precipitation, washing and drying to obtain a fully aromatic polyamide product. The fully aromatic polyamide synthesized by homopolymerization in the present invention can effectively improve the solubility of the polymer in organic solvents, which is beneficial to dissolving aromatic polyamide in organic solvents for spinning and other processing techniques, and the fully aromatic polyamide prepared at the same time The molecular chain of aromatic polyamide is regular and rigid, which avoids the decline of mechanical properties and expands the application field of fully aromatic polyamide.

Owner:CHINA PETROLEUM & CHEM CORP +1

A microcellular foaming injection molding process with high foaming ratio and no bubble marks on the surface

Owner:SHANDONG UNIV

Environment-friendly chest-protecting athletic undergarment having strong air permeability and high stability

InactiveCN109497634AImprove hydrophilicityHigh hydrophilic activityProtective garmentSpecial outerwear garmentsFiberEnvironmental resistance

The invention discloses an environment-friendly chest-protecting athletic undergarment having strong air permeability and high stability. The environment-friendly chest-protecting athletic undergarment comprises a back support, adjustable shoulder straps, a cover bellyband, a zipper and a sweat absorbing cushion, wherein the outer side of the back support is connected with the cover bellyband through the adjustable shoulder straps, the lower end of the cover bellyband is provided with the zipper, the sweat absorbing cushion is plug-connected in the cover bellyband and also comprises a modal fabric layer, a water-absorbing sponge layer and a cotton spun fabric layer, the modal fabric layer serves as an innermost side layer, the upper surface of the modal fabric layer is provided with the water-absorbing sponge layer, the upper surface of the water-absorbing sponge layer is provided with the cotton spun fabric layer, the water-absorbing sponge layer is prepared from polyether polysaccharide, toluene diisocyanate, dichloromethane, organic silicone oil, porous adsorption powder, dimethyl ethanolamine, stannous caprylate, cellulose, super absorbent resin, deionized water, high purity ammonium sulfate, soft long filament and chitin fiber. The air permeability and mechanical property of the environment-friendly chest-protecting athletic undergarment can be improved.

Owner:长沙浩然医疗科技有限公司

A method for improving the mechanical properties of carbon fiber reinforced aluminum matrix composites

A method for improving the mechanical properties of a carbon fiber reinforced aluminum matrix composite material relates to a method for improving the mechanical properties of a carbon fiber reinforced aluminum matrix composite material. The purpose is to solve the problem that the interface between aluminum alloy and carbon fiber is easy to generate interface product Al during the preparation of existing carbon fiber reinforced aluminum matrix composites. 4 C 3 The problem. Method: take aluminum cerium master alloy and aluminum alloy as raw materials, heat and melt aluminum alloy at high temperature, then add aluminum cerium master alloy and stir to obtain aluminum alloy melt containing cerium; carry out pressure impregnation and heat treatment. The present invention utilizes the principle of thermodynamics to segregate and precipitate on the grain boundary by adding easily segregated elements, thereby improving the interface contact state between the carbon fiber and the aluminum matrix, reducing the surface energy of the grain boundary, and reducing the interface reaction, thereby inhibiting the carbon fiber and the aluminum matrix. Interfacial reaction, reduce the damage of carbon fiber, and improve the mechanical properties of composite materials. The invention is suitable for preparing carbon fiber reinforced aluminum matrix composite materials.

Owner:HARBIN INST OF TECH

Novel anti-corrosion coating and preparation method thereof

ActiveCN105838186BGood dispersionIncrease binding areaPretreated surfacesAnti-corrosive paintsPolymer scienceSURFACTANT BLEND

The invention discloses a novel anti-corrosion coating and a preparation method of the coating, which solves the problem that the existing fly ash anti-corrosion coating is difficult to disperse and the mechanical properties of the coating are reduced. The present invention uses the reflux method to graft phenylphosphonic acid and surfactant on the surface of fly ash, so that the phenylphosphonic acid and surfactant are hydrolyzed in the heating process, and then connect with some hydroxyl groups on the surface of fly ash, grafting The final fly ash eventually becomes sea urchin-like particles. Among them, the presence of phenylphosphonic acid improves the dispersion of fly ash particles in the resin and the bonding area with the resin, thereby greatly increasing the wear resistance of the coating; at the same time, the presence of phenylphosphonic acid and surfactants The corrosion inhibitor can be more evenly dispersed into the nano-micropores of the fly ash, and its corrosion inhibition effect can be exerted, and the anti-corrosion performance of the coating can be enhanced at the same time.

Owner:NORTHEAST GASOLINEEUM UNIV

A highly weather-resistant, low-cost seawater corrosion-resistant steel bar and its production process

ActiveCN108251746BReasonable design of chemical compositionReduce corrosion rateProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

A segmental rolling method for large superalloy high cylindrical forgings

ActiveCN108746440BImprove mechanical propertiesQuality improvementMetal rollingAlloyMechanical property

Owner:WUXI PAIKE HEAVY CASTING & FORGING

A drop-resistant and deformation-resistant paper packaging box and its preparation process

ActiveCN112478367BIncreasing the thicknessImprove securityCarbon fibresBox making operationsFiberPolymer science

The invention discloses a drop-resistant and deformation-resistant paper packaging box and a preparation process thereof. The packaging box is made of an outer layer, an outer sponge, an intermediate layer, an inner sponge and an inner layer by thermocompression bonding, and the outer layer and the inner layer are impregnated with carbon fiber and kraft paper with surface active groups increased after surface grafted polyurethane treatment, Synthesized by hot pressing, the outer sponge and the inner sponge are high-concentration polyurethane sponges, which have good energy absorption and recovery capabilities, and the middle layer is made of high-density polyethylene, compatibilizer, thermoplastic polyurethane, and light calcium carbonate. . The invention has the ability of anti-tension, anti-drop and anti-deformation, and can more effectively protect the box body and the articles in the box body.

Owner:江阴市新艺彩印包装有限公司

A bentonite-based composite waterstop strip

The invention discloses a bentonite based composite sealing rod, and belongs to the technical field of building materials. The developed bentonite based composite sealing rod comprises modified bentonite, a water absorbent resin, poly-allylamine, a rubber compound, a tackifying resin, a plasticizer and an antiager. In the preparation process, the rubber is plasticated firstly to obtain a plasticated rubber, then the plasticated rubber, the modified bentonite, the water absorbent resin, the plasticizer, the antiager, the tackifying resin and the poly-allylamine are mixed, extracted and formed to obtain the bentonite based composite sealing rod, wherein the modified bentonite is prepared by mixing and ball-milling the bentonite, isocyanate and a coupling agent.

Owner:上安实业江苏有限公司

Preparation method for improving mechanical property of giant magnetostrictive material

Owner:UNIV OF SCI & TECH BEIJING

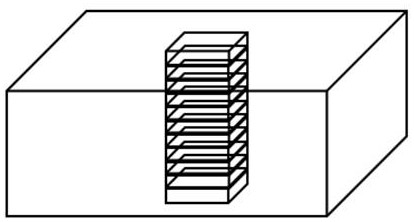

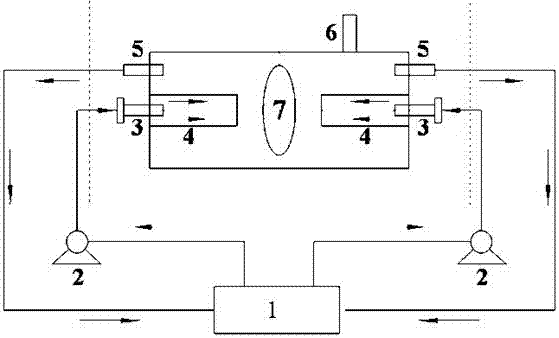

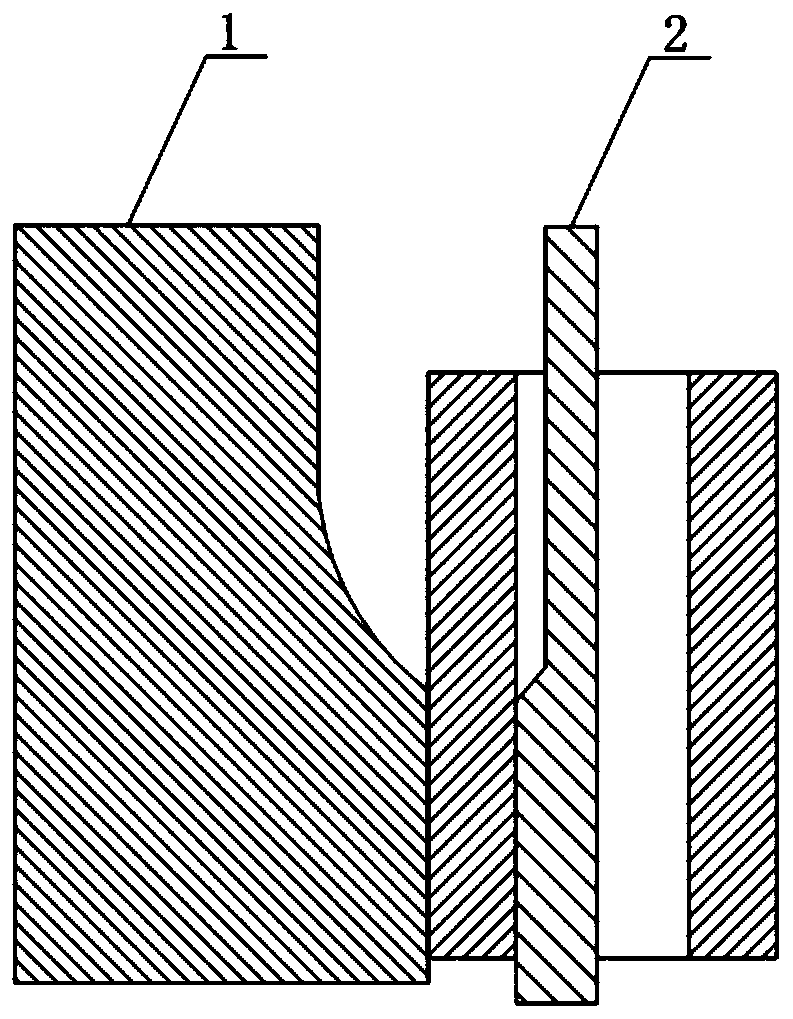

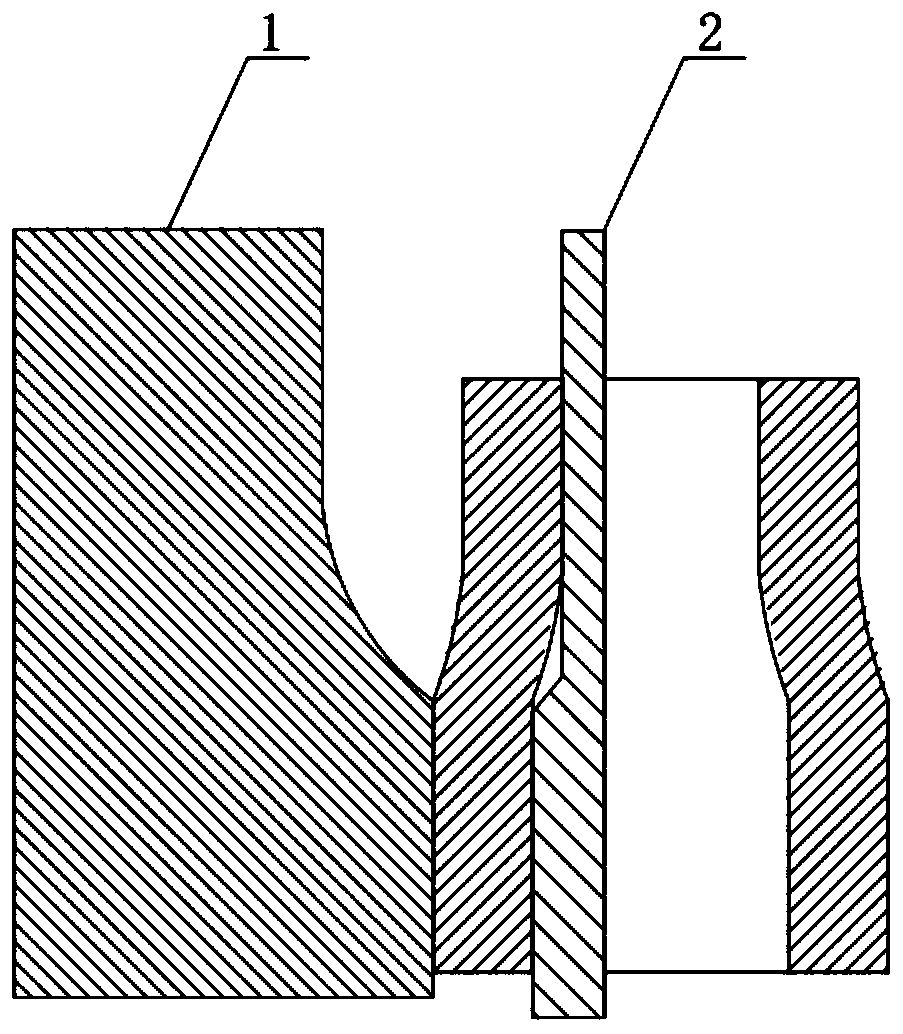

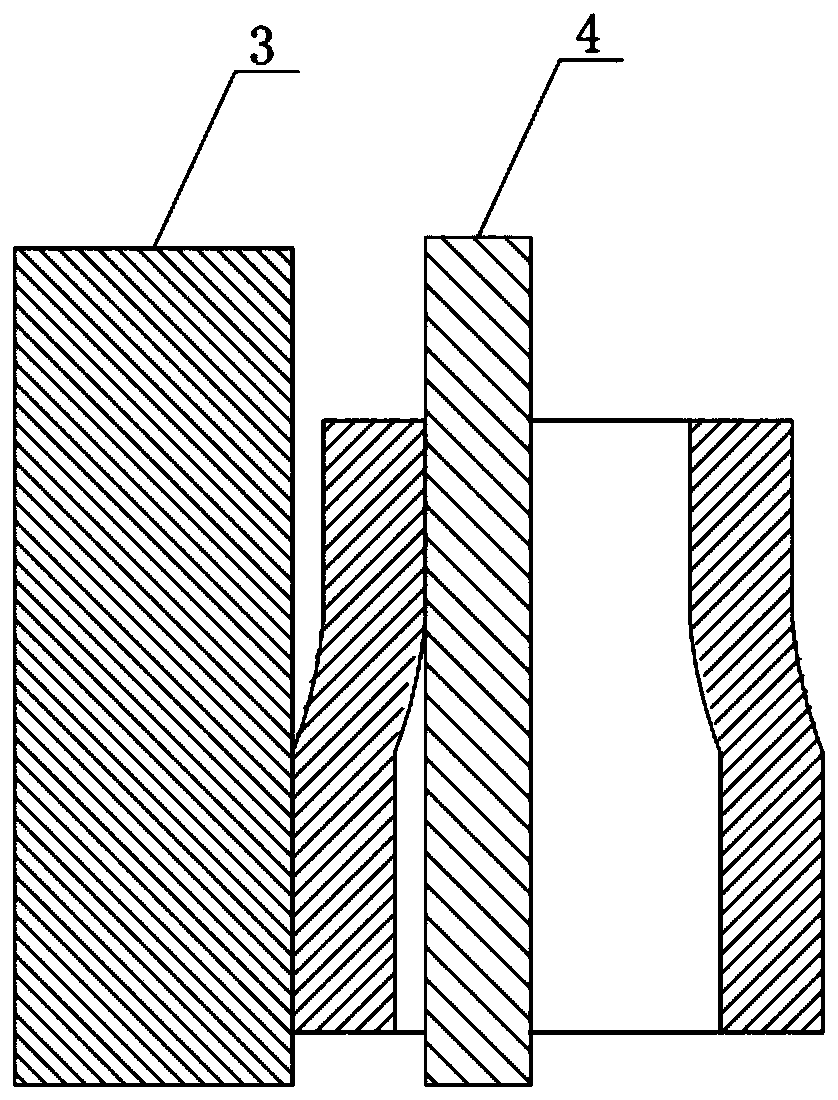

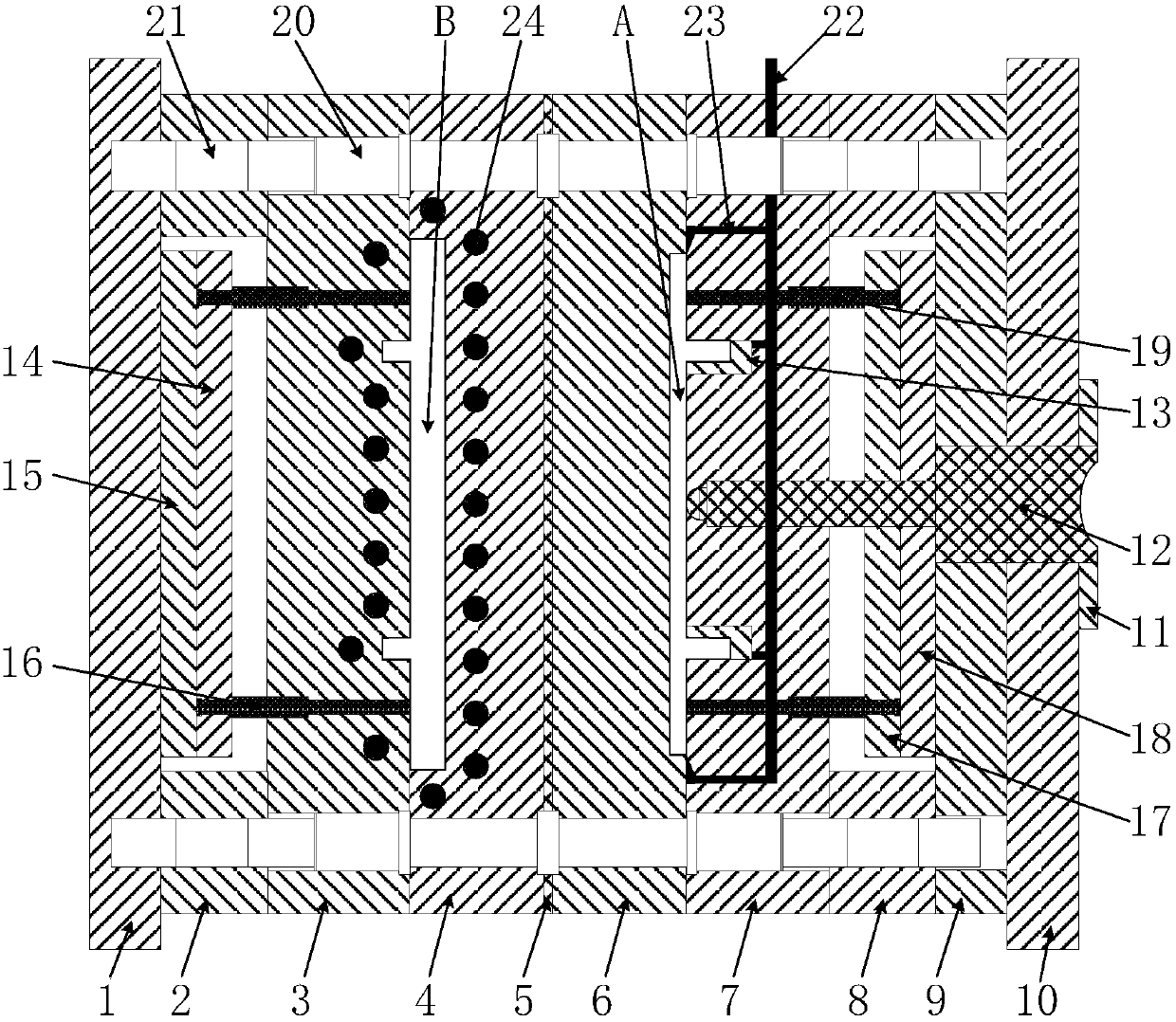

A laminated mold and process method for microcellular foaming injection molding

The invention discloses a laminated mold and a process method for microcellular foaming injection molding. The laminated mold includes at least two cavities with different volumes, the smaller one is the preform molding cavity, and the larger one is the final product molding cavity; the template participating in the preform molding is provided with gas for controlling the cavity pressure In and out of the pipeline, heating / cooling components for controlling the temperature of the mold are set in the template that participates in the molding cavity of the final product. In the present invention, a preform containing a foaming agent but without a cell structure is first molded, and then the preform is transferred into a molding cavity of a final product, and the preform is foamed and expanded by heating the mold until the entire cavity is filled. The laminated mold and its technology involved in the invention can obtain plastic parts with no bubble marks on the surface, dense inner bubbles and high expansion ratio without prolonging the injection molding production cycle.

Owner:SHANDONG UNIV

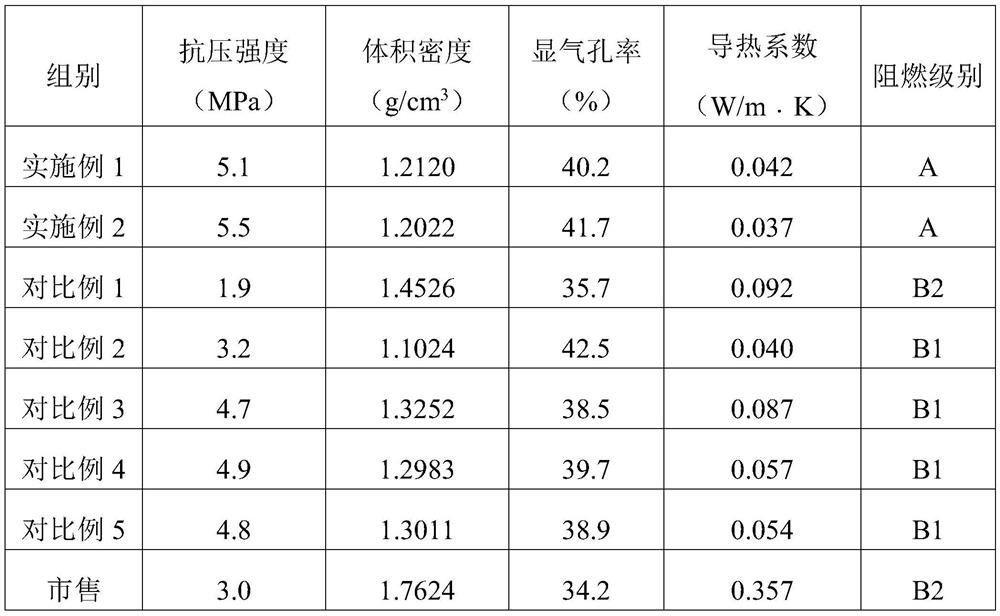

Flame-retardant wall brick

The invention provides a flame-retardant wall brick. The flame-retardant wall brick is prepared from the following raw materials in parts by weight: 100-200 parts of white cement, 50-100 parts of expanded polystyrene, 15-30 parts of porous flame-retardant hollow microspheres, 50-100 parts of silicon oxide aerogel, 10-20 parts of bentonite or modified bentonite, 5-12 parts of feldspar, 1-3 parts of a water-retaining agent, 5-10 parts of fibers and 2-5 parts of calcium carbonate. The flame-retardant wall brick has good fireproof, moisture-proof, heat-insulating and sound-insulating properties and mechanical properties.

Owner:金枝

Anti-falling and anti-deformation paper packaging box and preparation process thereof

ActiveCN112478367AImprove performanceHigh tensile strengthCarbon fibresBox making operationsThermoplastic polyurethaneHot pressing

The invention discloses an anti-falling and anti-deformation paper packaging box and a preparation process thereof. The packaging box is formed by hot-pressing bonding of an outer layer, an outer sponge, a middle layer, an inner sponge and an inner layer, the outer layer and the inner layer are formed by dipping and hot-pressing of carbon fibers and kraft paper with increased surface active groupsafter surface grafting polyurethane treatment, the outer sponge and the inner sponge are high-concentration polyurethane sponges and have good energy absorption and recovery capacity, and the middlelayer is prepared by blending and modifying high-density polyethylene, compatibilizers, thermoplastic polyurethane and light calcium carbonate. The packaging box has tensile, anti-falling and anti-deformation capabilities, so that a box body and articles in the box body can be more effectively protected.

Owner:江阴市新艺彩印包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com