A drop-resistant and deformation-resistant paper packaging box and its preparation process

A preparation process and packaging box technology, applied in the field of paper products, can solve the problems of packaging box damage, damaged packaging items, etc., and achieve the effects of improving comprehensive performance, increasing mechanical properties, and improving interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A drop-resistant and deformation-resistant paper packaging box and its preparation process, the specific steps are as follows:

[0048] Step 1: Grafting and modifying the carbon fiber surface;

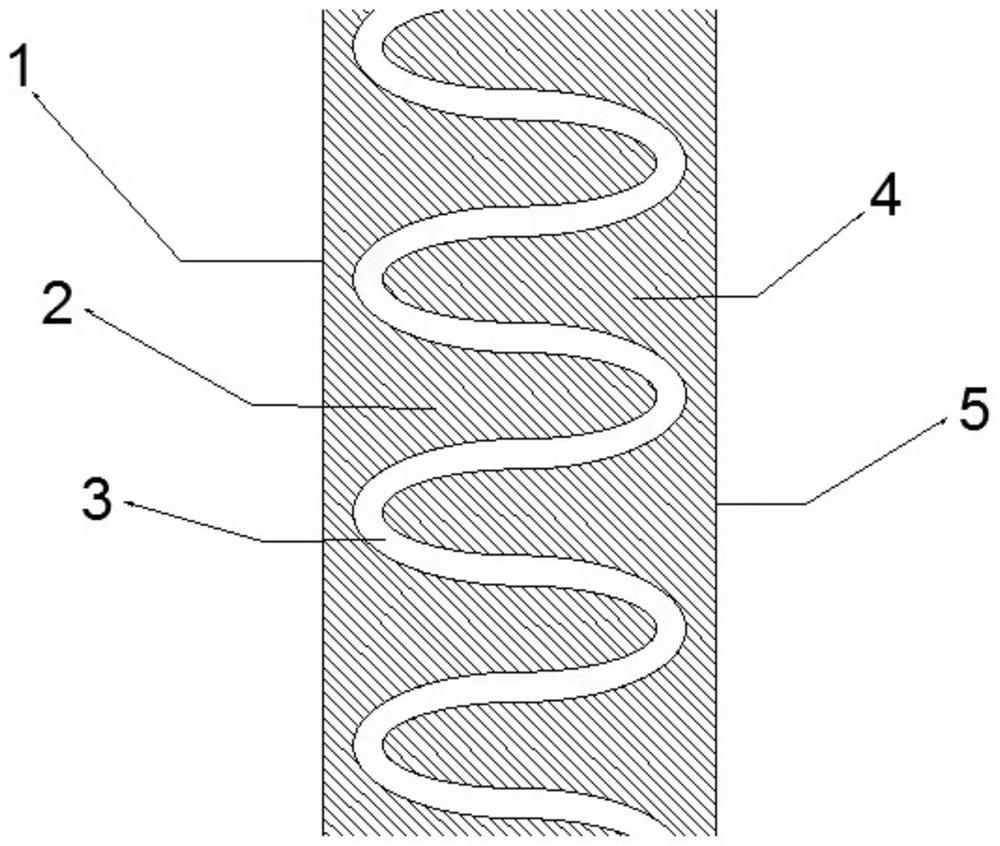

[0049] Step 2: impregnating the modified carbon fiber with two parts of kraft paper, and hot pressing to synthesize the outer layer 1 and the inner layer 5;

[0050] Step 3: Cutting two high-density polyurethane sponges to obtain outer sponge 2 and inner sponge 4;

[0051] Step 4: blending and modifying high-density polyethylene, compatibilizer, thermoplastic polyurethane, and light calcium carbonate to obtain an intermediate layer matrix;

[0052]Step 5: cutting and grinding the intermediate layer substrate to obtain the intermediate layer 3;

[0053] Step 6: Heat the prepared outer layer 1, inner layer 5, outer sponge 2, inner sponge 4 and middle layer 3 in the order of outer layer 1, outer sponge 2, middle layer 3, inner sponge 4 and inner layer 5. Press and bond to get th...

Embodiment 2

[0068] Step 1: Grafting and modifying the carbon fiber surface;

[0069] Step 2: impregnating the modified carbon fiber with two parts of kraft paper, and hot pressing to synthesize the outer layer 1 and the inner layer 5;

[0070] Step 3: Cutting two high-density polyurethane sponges to obtain outer sponge 2 and inner sponge 4;

[0071] Step 4: blending and modifying high-density polyethylene, compatibilizer, thermoplastic polyurethane, and light calcium carbonate to obtain an intermediate layer matrix;

[0072] Step 5: cutting and grinding the intermediate layer substrate to obtain the intermediate layer 3;

[0073] Step 6: Heat the prepared outer layer 1, inner layer 5, outer sponge 2, inner sponge 4 and middle layer 3 in the order of outer layer 1, outer sponge 2, middle layer 3, inner sponge 4 and inner layer 5. Press and bond to get the box paper;

[0074] Step 7: splicing and molding the packaging box papers bonded by thermocompression to form a packaging box.

[00...

Embodiment 3

[0088] A drop-resistant and deformation-resistant paper packaging box and its preparation process, the specific steps are as follows:

[0089] Step 1: Grafting and modifying the carbon fiber surface;

[0090] Step 2: impregnating the modified carbon fiber with two parts of kraft paper, and hot pressing to synthesize the outer layer 1 and the inner layer 5;

[0091] Step 3: Cutting two high-density polyurethane sponges to obtain outer sponge 2 and inner sponge 4;

[0092] Step 4: blending and modifying high-density polyethylene, compatibilizer, thermoplastic polyurethane, and light calcium carbonate to obtain an intermediate layer matrix;

[0093] Step 5: cutting and grinding the intermediate layer substrate to obtain the intermediate layer 3;

[0094] Step 6: Heat the prepared outer layer 1, inner layer 5, outer sponge 2, inner sponge 4 and middle layer 3 in the order of outer layer 1, outer sponge 2, middle layer 3, inner sponge 4 and inner layer 5. Press and bond to get t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com