Preparation method for improving mechanical property of giant magnetostrictive material

A technology of giant magnetostriction and material mechanics, applied in the field of magnetic materials, can solve the problems of poor mechanical properties of giant magnetostrictive materials, and achieve the effects of easy industrial production, improved mechanical properties, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: orientation Tb 0.27 Dy 0.73 Fe 1.95 The high-pressure heat treatment of the alloy is completed in the following steps:

[0022] 1. Preparation of Tb with orientation by batching, vacuum smelting, and directional solidification 0.27 Dy 0.73 Fe 1.95 Alloy, the size of which is 10mm in diameter and 100mm in length.

[0023] 2. Put the giant magnetostrictive material into a high-pressure heat treatment furnace, and start heating after vacuuming to 0.01Pa. And keep vacuuming during the heating process. After the temperature rises to 1020°C, stop vacuuming. Introduce high-purity argon to raise the pressure in the furnace to the specified pressure of 15MPa, and then keep it at 1020°C for 2h.

[0024] 3. Stop heating after the heat preservation is over, and take out the sample after cooling with the furnace.

[0025] 4. Machining.

[0026] 5. Finished product performance testing.

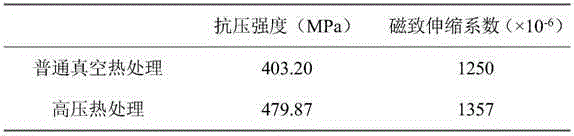

[0027] The comparison between its compressive performance and magnetostri...

Embodiment 2

[0030] Example 2: orientation Tb 0.27 Dy 0.73 Fe 1.95 The high-pressure heat treatment of the alloy is completed in the following steps:

[0031] 1. Preparation of Tb with orientation by batching, vacuum smelting, and directional solidification 0.27 Dy 0.73 Fe 1.95 Alloy, the size of which is 10mm in diameter and 100mm in length.

[0032]2. Put the giant magnetostrictive material into a high-pressure heat treatment furnace, and start heating after vacuuming to 0.01Pa. And keep vacuuming during the heating process. After the temperature rises to 1020°C, stop vacuuming. Introduce high-purity argon to raise the pressure in the furnace to the specified pressure of 20MPa, and then keep it at 1020°C for 2h.

[0033] 3. Stop heating after the heat preservation is over, and take out the sample after it cools down with the furnace.

[0034] 4. Machining.

[0035] 5. Finished product performance testing.

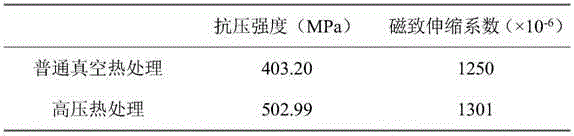

[0036] The comparison between its compressive performance and magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com