Method for controlling directional growth of alloy grains in laser additive manufacturing process

A laser additive and manufacturing process technology, applied in the field of materials, can solve the problems of low temperature creep performance of alloys, difficult grain orientation, etc., and achieve the effects of reducing miscellaneous crystals, low cost, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: First establish the 3D solid model that needs to be prepared, layer it, plan the deposition path of each layer, and import the file into the equipment control system.

[0042] Step 2: After that, pre-treat the selected substrate, remove the surface oxide layer, clean and dry it for later use.

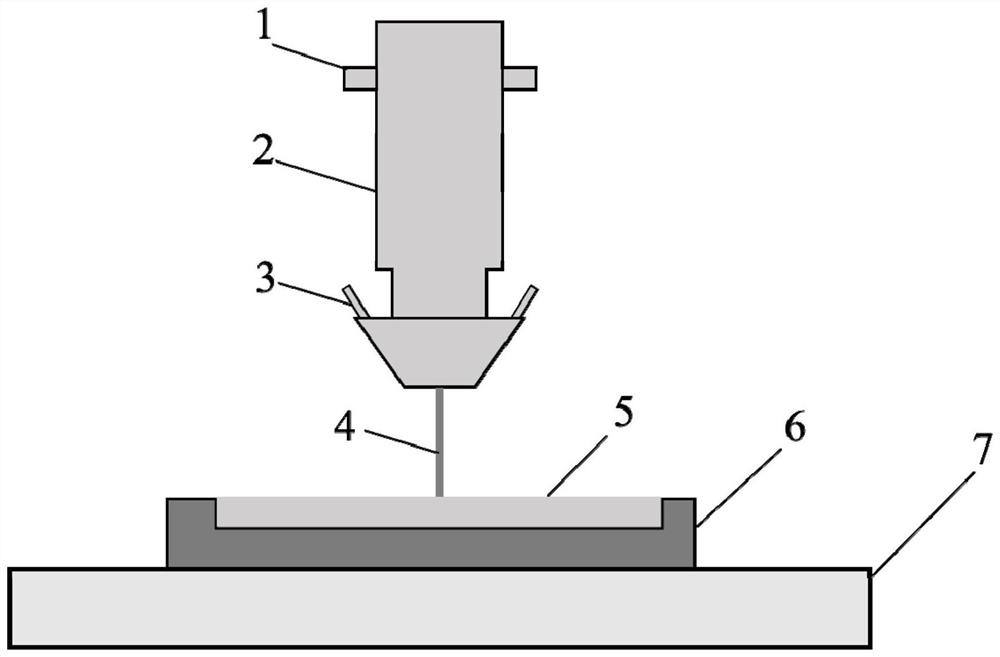

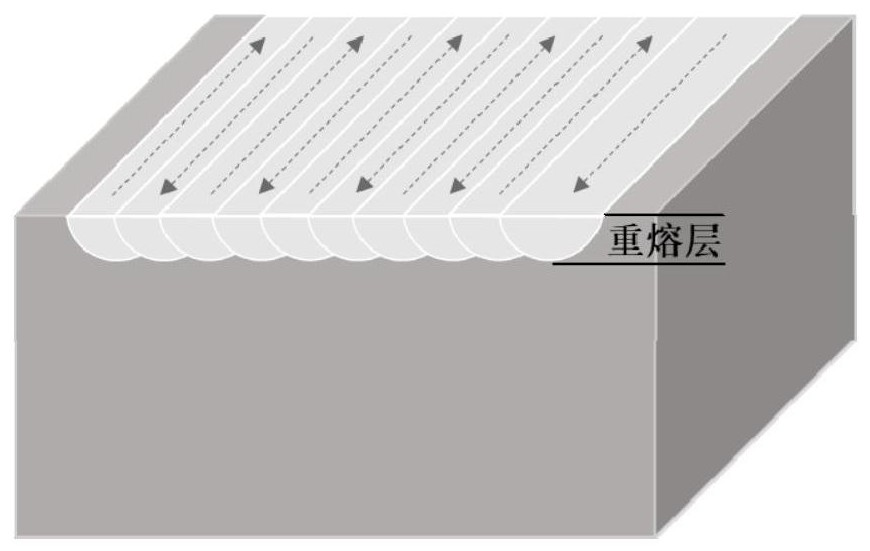

[0043] Step 3: Fix the processed substrate on the workbench and perform laser surface remelting, such as figure 2 shown. The laser scanning path in this step depends on the shape of the first layer of material to be deposited on it.

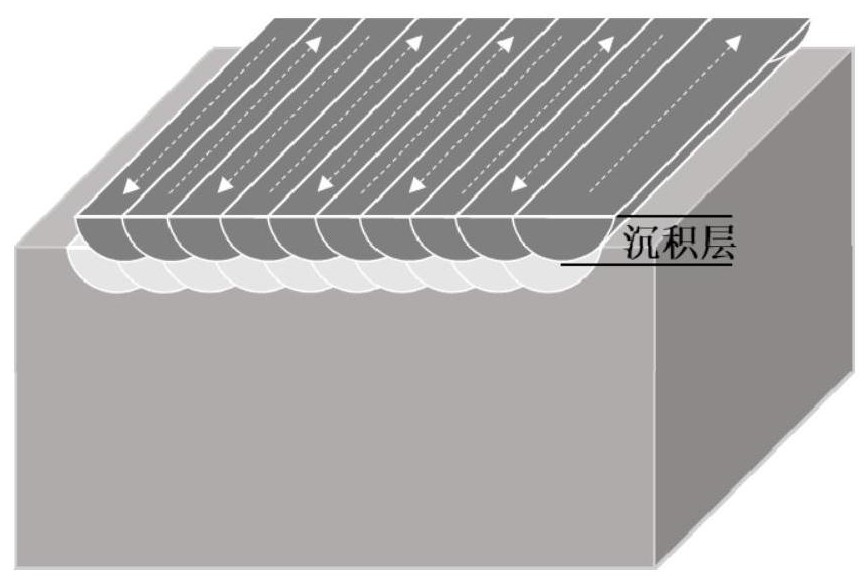

[0044]Step 4: Use laser additive manufacturing technology to print the first layer. The schematic diagram of the laser scanning path is as follows image 3 (The shape in the figure is only for illustration and does not represent the actual material properties). This step is repeated until all layers are printed, and the prepared component can be obtained.

[0045] result:

[0046] The microstructure of the sample directly manufactured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com