Synthesis method of wholly aromatic polyamide

A wholly aromatic and synthetic method technology, applied in the field of synthesis of wholly aromatic polyamides, can solve the problems of loss of mechanical properties of materials, reduce the degree of tight packing of molecular chains, and achieve regularity of molecular chains and avoid mechanical properties. The effect of falling and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

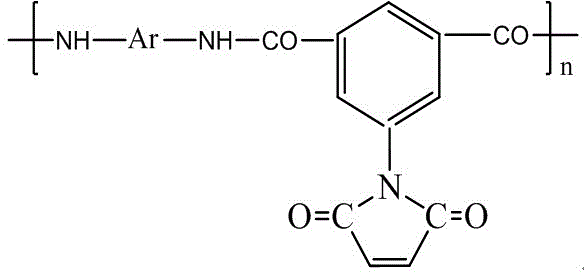

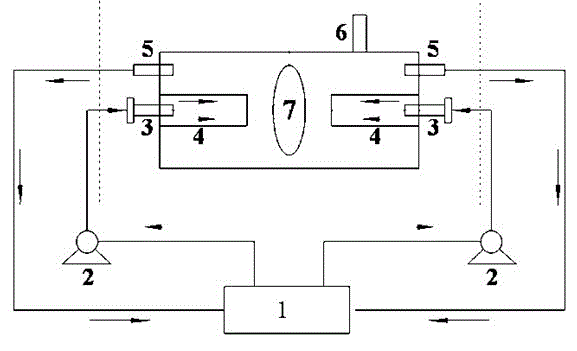

[0031]Add 18.1g (0.1mol) of 5-aminoisophthalic acid, 10.8g (0.11mol) of maleic anhydride, 20mL of dehydrating agent acetic anhydride and 20mmol of catalyst anhydrous sodium acetate into 150mL of acetone solvent, and stir to dissolve the material. Then, the mixed solution was put into the premixing tank of the impinging flow reactor and mixed. The solution is input to the feed port of the impinging flow reactor through the pump, and the liquid flow flows to the center surface of the container through the guide tube at a high speed under the pressure, and reacts with a frontal collision at the center. The reaction temperature is controlled at 55°C, and the system The internal pressure is 0.3MPa, and the impacted liquid material flows back to the premixing tank from the outlets on both sides, and then is pumped to the feed port of the impacting flow reactor for reaction to realize continuous reaction, and the reaction time is 50 minutes. After the reaction is finished, cool the r...

Embodiment 2

[0036] The method for preparing polymeric monomer 5-maleimide isophthalic acid is the same as Example 1.

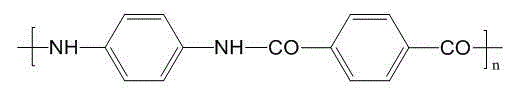

[0037] Add 15g of solubilizing anhydrous lithium chloride to the mixed solvent of triphenyl phosphite (500ml) / pyridine (500ml) / N,N-dimethylacetamide (250ml), gradually raise the temperature and stir to 50°C, wait After lithium chloride was completely dissolved, 26.1 g (0.1 mol) of 5-maleimidoisophthalic acid and 20 g (0.1 mol) of 4,4′-diaminodiphenyl ether were added. The temperature was raised to 90° C. under stirring condition, and the reaction was carried out for 5 hours. After the reaction system was cooled to room temperature, the reaction solution was poured into excess methanol, and a precipitate was formed under stirring conditions. The precipitated product was filtered with suction, washed with methanol, and dried in a vacuum oven at 150°C for 24 hours to obtain a fully aromatic polyamide product 38.7 g, the yield is 83.8%. The prepared aromatic polyamide (mole...

Embodiment 3

[0041] Add 18.1g (0.1mol) of 5-aminoisophthalic acid, 10.8g (0.11mol) of maleic anhydride, 20mL of dehydrating agent acetic anhydride and 10mmol of catalyst triethylamine into 150mL of pyridine solvent, and stir to dissolve the material. Then, the mixed solution was put into the premixing tank of the impinging flow reactor and mixed. The solution is input to the feed port of the impingement flow reactor through the pump, and the liquid flow flows to the center surface of the container through the guide tube at a high speed under the pressure, and reacts with a frontal impact at the center. The reaction temperature is controlled at 65°C, and the system The internal pressure is 1.5MPa, and the impacted liquid material flows back to the premixing tank from the outlets on both sides, and then is pumped to the feed port of the impacting flow reactor for reaction to realize continuous reaction, and the reaction time is 60 minutes. After the reaction is finished, cool the reaction li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com