High-strength corrosion-resistant aluminum alloy and preparation method thereof

A corrosion-resistant aluminum alloy, high-strength technology, applied in the field of aluminum alloy materials, can solve the problems of low strength and hardness of the alloy, insufficient strength, low strength and hardness, etc., to increase the ductility and corrosion resistance of the alloy, improve welding performance, The effect of improving the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a high-strength corrosion-resistant aluminum alloy, comprising the following steps: (a) Melting an intermediate alloy: using pure zinc ingots, pure aluminum ingots and pure magnesium ingots for Zn, Al, and Mg, and using aluminum-silicon ingots for Si, Fe, Mn, Cu, and Cr Master alloys, aluminum-iron master alloys, aluminum-manganese master alloys, aluminum-copper master alloys and aluminum-chromium master alloys; put the pure aluminum ingots into the furnace, set the furnace gas temperature to 760°C, and keep the pure aluminum ingots for 30 minutes after melting for slag removal , and then add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-iron master alloy and pure magnesium ingots into the melting furnace in order according to the block weight and size from large to small, and then raise the temperature of the furnace gas by 15°C and keep it warm until the master alloy and After the magnesium ingots are completely melted, ...

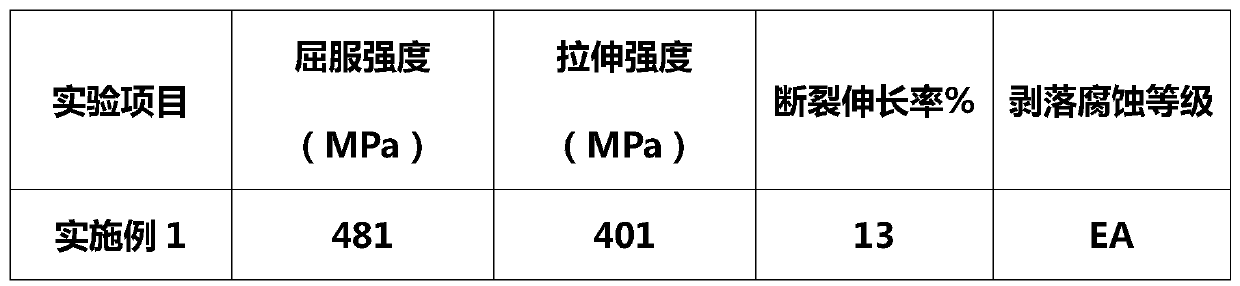

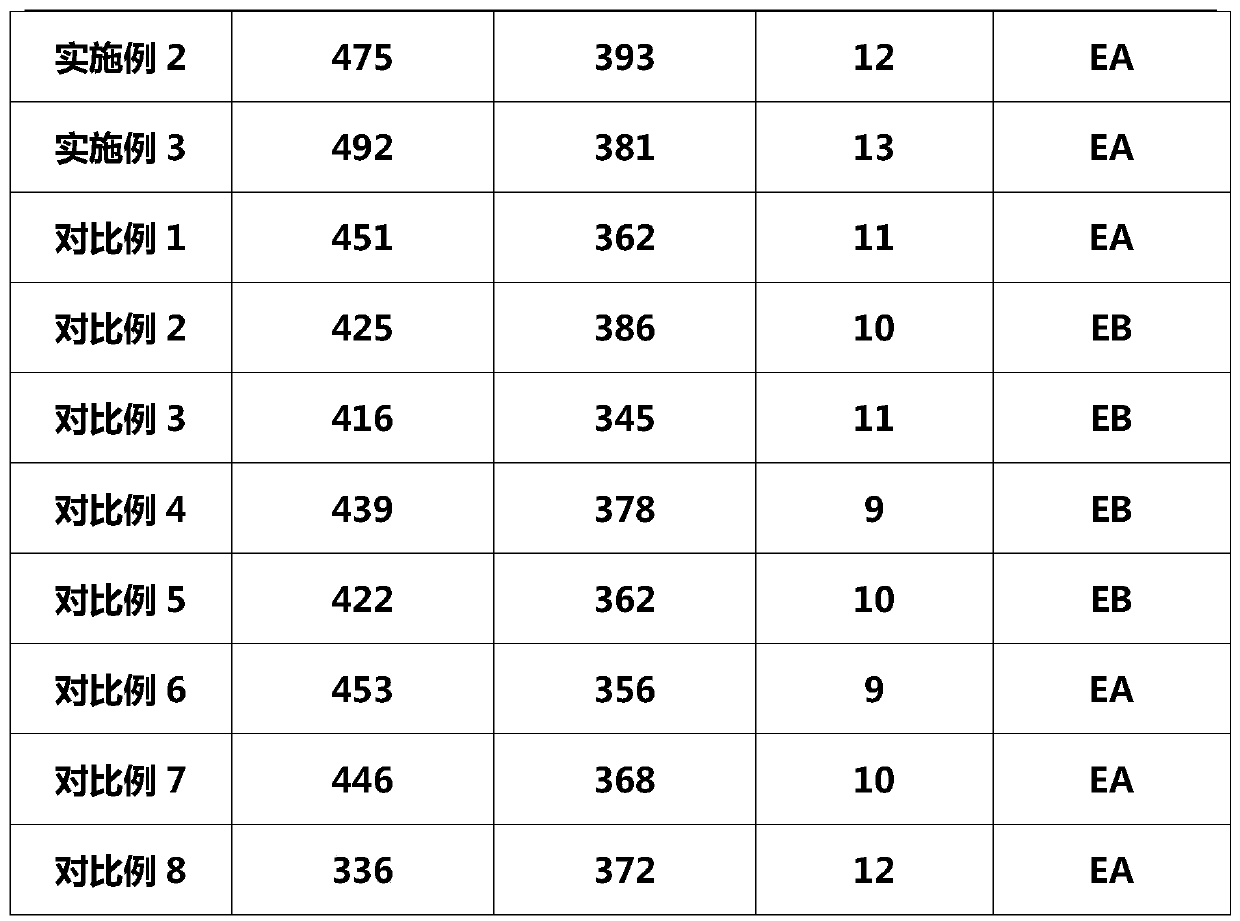

Embodiment 1

[0031]A high-strength corrosion-resistant aluminum alloy, the high-strength corrosion-resistant aluminum alloy includes the following components: 1.6% Mg, 1.7% Si, 0.8% Mn, 0.25% Cu, 0.6% Zn, 0.2% Fe, 0.14% Cr, 0.2% Other alloying elements, the balance is Al. The rare earth elements include: 70% Gd, 20% La, 10% Eu. Said other alloy elements include the combination of Ni, V, Ti, Zr and rare earth elements in a ratio of 0.3:1.7:0.5:1.5:0.2.

Embodiment 2

[0033] A high-strength corrosion-resistant aluminum alloy, the high-strength corrosion-resistant aluminum alloy includes the following components: 1.3% Mg, 2.0% Si, 0.7% Mn, 0.4% Cu, 0.3% Zn, 0.1% Fe, 0.08% Cr, 0.1% Other alloying elements, the balance is Al; other alloying elements include Ni, V, Ti, Zr, and combinations of rare earth elements, and the ratio is 0.4:1.6:0.6:1.4:0.2. The rare earth elements include: 70% Gd, 20% La, 10% Eu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com