Method for improving mechanical property of carbon fiber-reinforced aluminum matrix composite

A technology for strengthening aluminum-based and composite materials, applied in the field of improving the mechanical properties of carbon fiber reinforced aluminum-based composite materials, achieving the effects of improved mechanical properties, simple preparation process, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

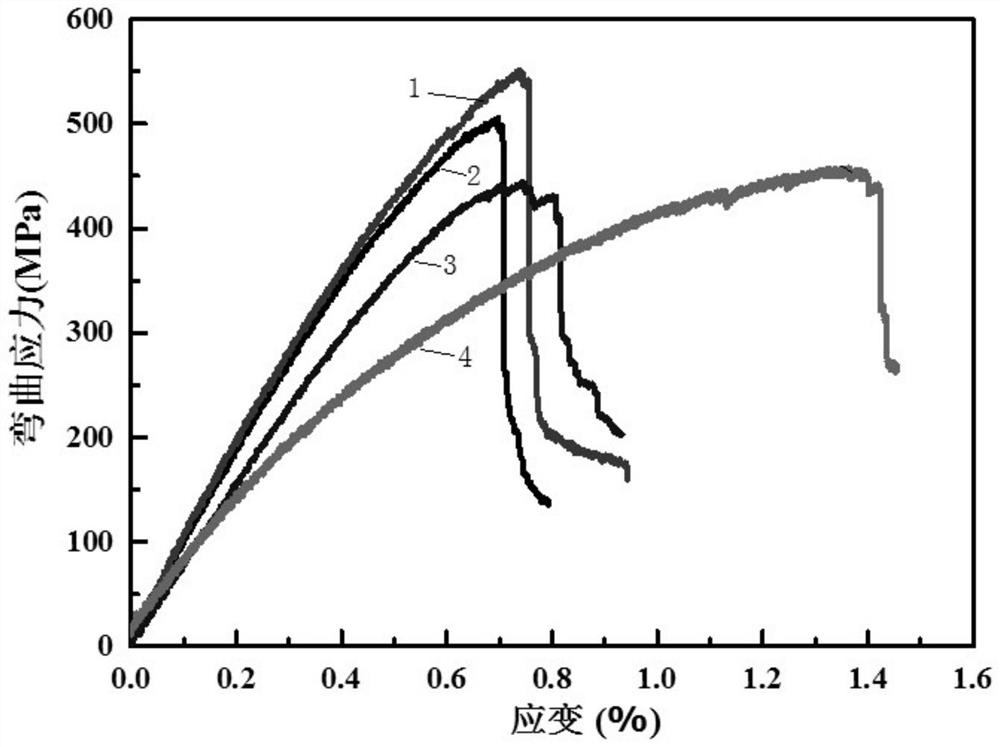

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: The method for improving the mechanical properties of carbon fiber reinforced aluminum matrix composites in this embodiment is carried out according to the following steps:

[0016] 1. Weighing materials: taking aluminum-cerium master alloy and aluminum alloy as raw materials, the mass fraction of cerium element in the raw materials is 0.05-0.9%;

[0017] 2. Mixed melting: heating and melting the aluminum alloy weighed in step 1 at high temperature, then adding an aluminum-cerium intermediate alloy and stirring to obtain an aluminum alloy melt containing cerium;

[0018] 3. Forming: put the carbon fiber reinforced body into the mold and preheat it, pour the aluminum alloy melt containing cerium obtained in step 2 into the mold, and perform pressure infiltration to obtain a carbon fiber reinforced aluminum matrix composite material; pressure infiltration process In the process, the aluminum alloy melt containing cerium obtained in step 2 is poured into the ...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is different from Embodiment 1 in that: the mass fraction of cerium element in the raw material in step 1 is 0.05-0.9%.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the mass fraction of cerium in the raw material in step 1 is 0.1-0.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com