Novel anti-corrosion coating and preparation method thereof

A new type of anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of polluted fluid, low efficiency, reduced mechanical properties of coatings, etc., to enhance anti-corrosion performance and increase wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Metal surface pretreatment:

[0048] Use sandblasting to quickly surface-treat the metal surface and put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface. The mass concentration of the ethanol solution is 75%, take it out and dry it naturally, and save it for later use;

[0049] (2) Preparation of anti-corrosion coating emulsion:

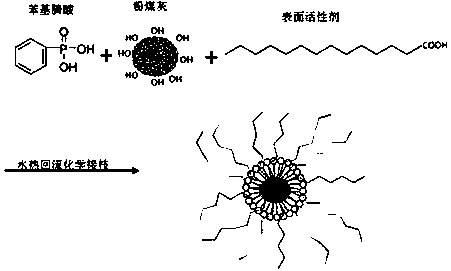

[0050] ①Put the fly ash that has been ground and passed through a 300-mesh sieve into a sodium hydroxide solution with pH=8 and stir for 8 hours, then filter and dry to obtain alkali-treated fly ash;

[0051] ② After adding 5 parts of phenylphosphonic acid, 5 parts of kh550 and 5 parts of water to 40 parts of alkali-treated fly ash, add them to the reflux device already equipped with 50 parts of ethanol, react at 60°C for 6 hours, filter and dry after reaction Dry;

[0052] ③ Pour 20 parts of saturated water-soluble imidazoline corrosion inhibitor solution into the fly ash a...

Embodiment 2

[0069] (1) Metal surface pretreatment:

[0070] Use 400-mesh sandpaper to quickly polish the metal surface, then put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface.

[0071] (2) Preparation of emulsion used for coating:

[0072] ①Put the fly ash that has been ground and passed through a 350-mesh sieve into a sodium hydroxide solution with pH=9 and stir for 9 hours, then filter and dry to obtain alkali-treated fly ash;

[0073] ② Add 0.5 parts of phenylphosphonic acid and 1 part of stearic acid to 30 parts of fly ash after alkali treatment, add them into the reflux device already equipped with 40 parts of ethanol, react at 70°C for 7 hours, filter and dry after reaction ;

[0074] ③ Pour 15 parts of saturated water-soluble benzotriazole solution into the fly ash after the grafting treatment in step ②, stir evenly and then dry;

[0075] ④ After adding 5 parts of nano-carbon black to the mixture obtained in step ...

Embodiment 3

[0085] (1) Metal surface pretreatment:

[0086] Use 10MPa high-pressure water jet to treat the metal surface to remove impurities such as grease and dust on the surface. The pipeline is naturally dried and reserved for future use.

[0087] (2) Preparation of emulsion used for coating:

[0088] ①Put the fly ash that has been ground and passed through a 350-mesh sieve into a sodium hydroxide solution with pH=14 and stir for 9 hours, then filter and dry to obtain alkali-treated fly ash;

[0089] ② After adding 0.5 parts of phenylphosphonic acid and 2 parts of fluorosilane to 20 parts of alkali-treated fly ash, add them into the reflux device already equipped with 40 parts of ethanol, react at 80°C for 6 hours, filter and dry after reaction;

[0090] ③ Pour 10 parts of saturated water-soluble benzotriazole solution into the fly ash after the grafting treatment in step ②, stir evenly and then dry;

[0091] ④ Pour 20 parts of ethyl acetate solvent into the dried product in step ③,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com