Thermoplastic fiber metal laminate and preparation method thereof

A thermoplastic fiber, laminate technology, applied in metal layer products, chemical instruments and methods, lamination and other directions, can solve the overall mechanical properties of fiber metal laminates, uneven dispersion of thermoplastic resin, interlayer separation damage and other problems , to avoid the reduction of the mechanical properties of the material, improve the interlayer bonding force and mechanical properties, and achieve the effect of uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

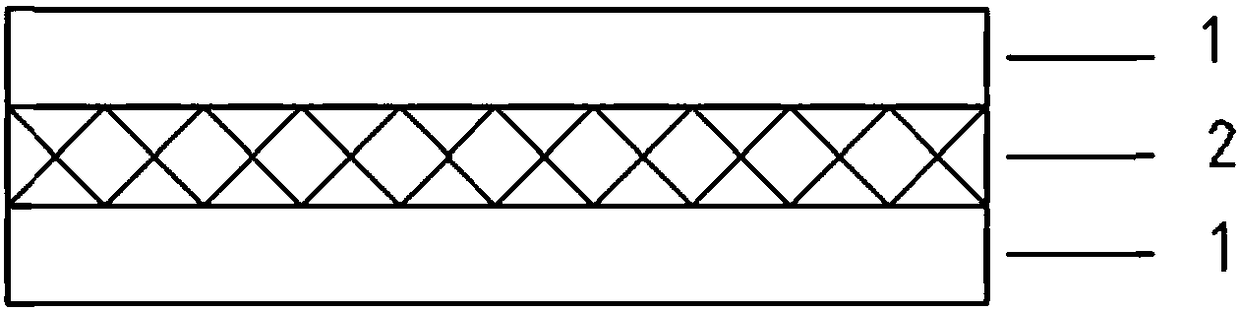

[0016] The present invention provides a method for preparing a thermoplastic fiber-metal laminate, which includes the following steps: S1, providing a thermoplastic mixed fiber braid; S2, superimposing and arranging the thermoplastic mixed fiber braid and metal material layers to form Laminated board; S3, pressing the laminated board under hot pressing conditions, and then forming the thermoplastic fiber metal laminated board under cooling conditions, wherein the thermoplastic mixed fiber braid is woven from fiber bundles, and the fiber bundles It also includes thermoplastic fiber materials and reinforced fiber materials.

[0017] The preparation method of the thermoplastic fiber metal laminated board provided by the present invention can save the step of preparing the prepreg board by using the thermoplastic mixed fiber braid instead of the prepreg board, and utilizes that each fiber bundle in the thermoplastic fiber blend braid contains thermoplastic The characteristics of t...

Embodiment 1

[0041] It is used to illustrate the beneficial effects of the thermoplastic fiber metal laminate and its preparation method of the present invention. The specific preparation method is as follows:

[0042] (1) Put 0.4mm thick aluminum alloy sheets (200mm×100mm in length and width) (2 pieces) into 10% by weight aqueous sodium hydroxide solution for 30s, and then soak them in 5% by weight of nitric acid Soak in aqueous solution for 30s;

[0043] (2) Silane coupling agent KH550 (commercially purchased from Nanjing Aocheng Chemical Co., Ltd.) and ethanol are prepared in a silane coupling agent solution according to a weight ratio of 1:100, and the silane coupling agent solution is coated in the step (1) ) on the surface of two aluminum alloy sheets treated, and then dried in an oven at 80°C for 30min;

[0044] (3) Cut the thermoplastic mixed fiber braid A1 into the same size as the aluminum alloy sheet, and combine the thermoplastic mixed fiber braid A1 and the aluminum alloy sh...

Embodiment 2

[0048] It is used to illustrate the beneficial effects of the thermoplastic fiber metal laminate and its preparation method of the present invention.

[0049] Preparation method: Referring to Example 1, the difference is that the thermoplastic fiber-mixed braided fabric A2 is used instead of the thermoplastic mixed-fiber braided fabric A1 to obtain a thermoplastic fiber-metal laminate S2.

[0050] Microscopic observation of the cross-section of the fiber metal laminate S2 shows that the fiber metal laminate is composed of an aluminum alloy sheet, a resin-impregnated fiber layer (thickness 0.25mm) and an aluminum alloy sheet laminated in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com