Bentonite based composite sealing rod

A technology of bentonite and water-stop strips, which is applied in the field of building materials, can solve the problems of poor mechanical properties and expansion effects of water-stop strips, and achieve the effects of reducing mechanical properties, increasing glass transition temperature, and improving cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

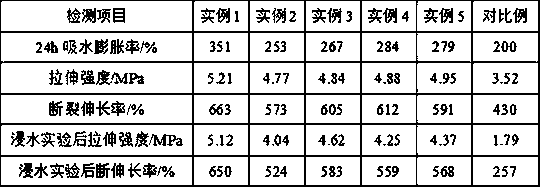

Examples

example 1

[0030] Pour bentonite and isocyanate into a ball milling tank at a mass ratio of 20:1, and add a silane coupling agent with a mass ratio of 8% of bentonite, then add zirconia ball milling beads at a mass ratio of 20:1, and ball mill for 6 hours. Pass through a 300-mesh sieve to obtain modified bentonite; in parts by weight, 30 parts of modified bentonite, 45 parts of water-absorbing resin, 15 parts of polyallylamine, 12 parts of rubber compound, 10 parts of tackifying resin, 3 parts of Plasticizer, 0.8 parts of anti-aging agent, firstly add the rubber compound into the plastic mixer, and masticate for 30 minutes at a temperature of 80°C to obtain plasticized rubber, then plasticized rubber, modified bentonite, water-absorbing resin, plasticized Agent, anti-aging agent, tackifying resin and polyallylamine were mixed at a temperature of 110°C for 15 minutes to obtain a mixed rubber, and the obtained mixed rubber was extruded through an extruder to obtain a bentonite-based composi...

example 2

[0032] According to the mass ratio of 20:1, pour the bentonite into the ball mill jar, and add 8% silane coupling agent of the mass of bentonite, then add zirconia ball milling beads according to the mass ratio of the ball to material at 20:1. After ball milling and mixing for 6 hours, pass 300 mesh sieve to obtain modified bentonite; in parts by weight, successively get 30 parts of modified bentonite, 45 parts of water-absorbing resin, 15 parts of polyallylamine, 12 parts of rubber compound, 10 parts of tackifying resin, and 3 parts of plasticizer , 0.8 parts of anti-aging agent, first add the rubber compound into the plastic mixer, and masticate for 30 minutes at a temperature of 80°C to obtain plasticized rubber, and then plasticized rubber, modified bentonite, water-absorbing resin, plasticizer, Anti-aging agent, tackifying resin and polyallylamine were kneaded for 15 minutes at a temperature of 110°C to obtain a mixed rubber, and the obtained mixed rubber was extruded thro...

example 3

[0034]Pour bentonite and isocyanate into a ball milling tank at a mass ratio of 20:1, and add a silane coupling agent with a mass ratio of 8% of bentonite, then add zirconia ball milling beads at a mass ratio of 20:1, and ball mill for 6 hours. Pass through a 300-mesh sieve to obtain modified bentonite; in parts by weight, take 30 parts of modified bentonite, 45 parts of water-absorbing resin, 12 parts of rubber compound, 10 parts of tackifying resin, 3 parts of plasticizer, and 0.8 part of anti-aging Add the rubber compound to the plasticizer first, and masticate for 30 minutes at a temperature of 80°C to obtain the plasticized rubber, and then add the plasticized rubber, modified bentonite, water-absorbing resin, plasticizer, anti-aging agent, The viscose resin was mixed for 15 minutes at a temperature of 110°C to obtain a compounded rubber, and the obtained mixed rubber was extruded through an extruder to obtain a bentonite-based composite waterstop strip. The bentonite is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com