Segmentally rolling method for large-scale high-temperature alloy high-cylindrical forging piece

A high-temperature alloy and segmental rolling technology, which is applied in the field of alloy forging, can solve the problems that the mechanical properties of forgings cannot reach the mechanical properties, reduce the strength and elongation of welding materials, and the production economy cannot be guaranteed, so as to avoid mechanical The effect of performance reduction, strength assurance, and improvement of mechanical properties and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

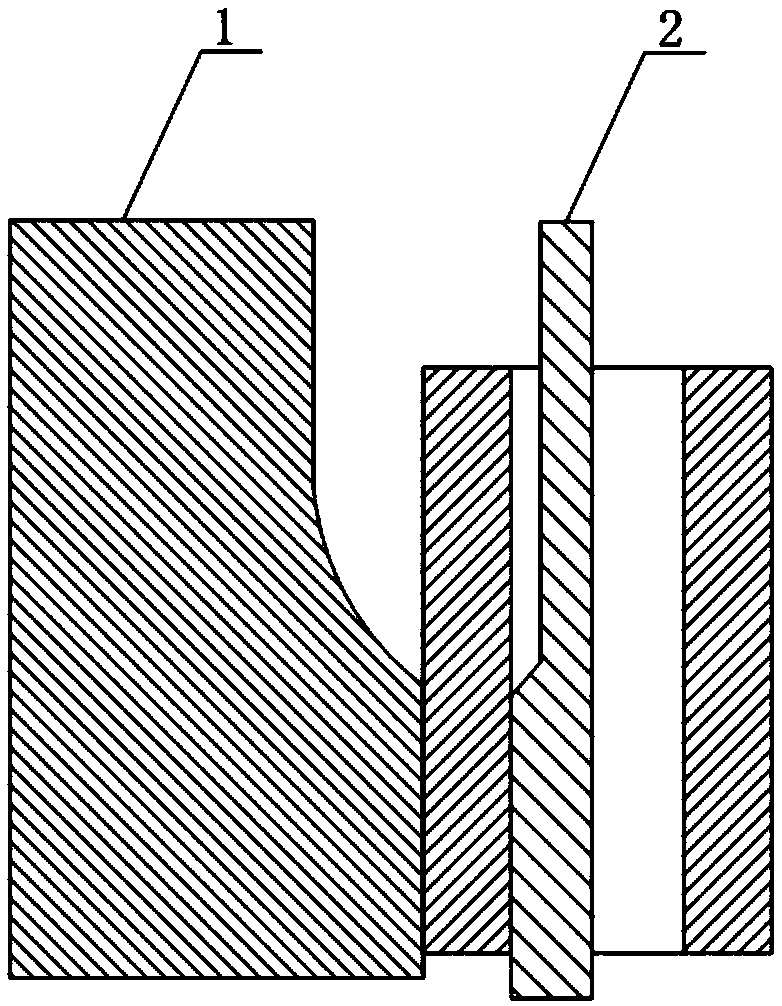

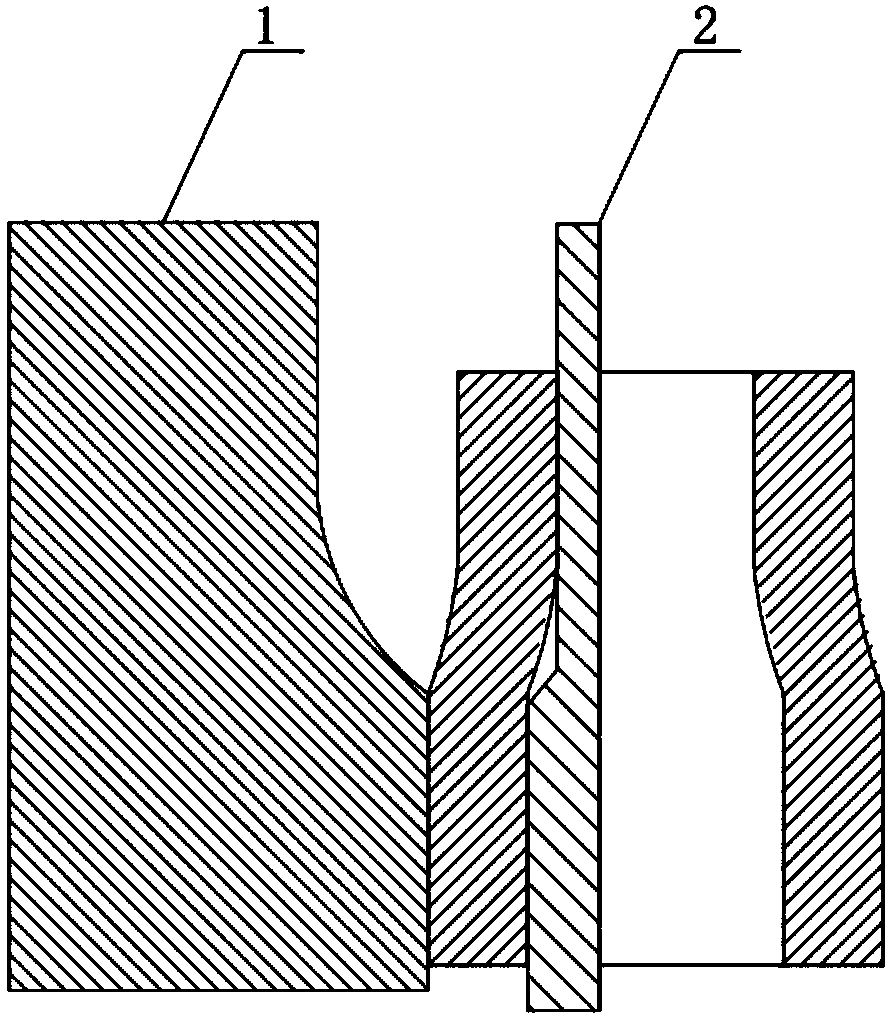

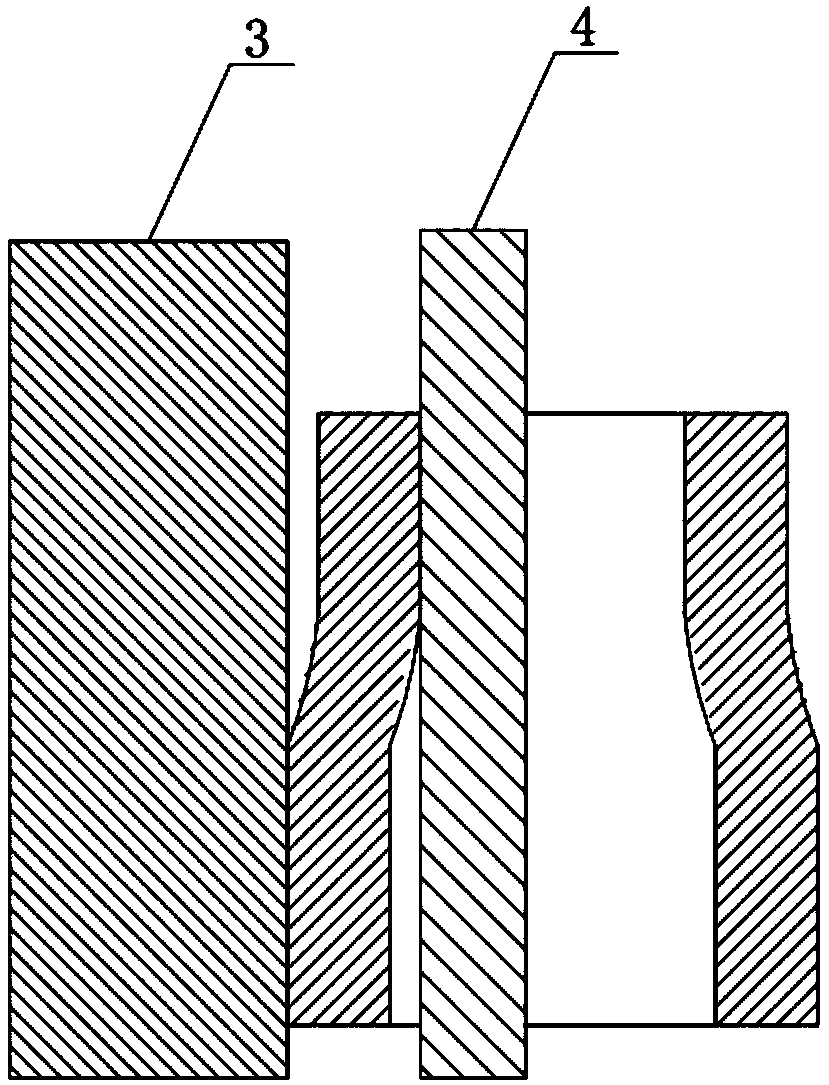

[0030] In the segmental rolling method of large superalloy high cylindrical forgings in this embodiment, the ring blank is first segmented and partially rolled by a segmented special-shaped die, and then the partially rolled ring is integrally rolled by a straight wall die. , the segmented special-shaped mold includes a special-shaped main roll 1 and a special-shaped core roll 2, and the roll surface of the special-shaped main roll 1 and the special-shaped core roll 2 is in partial contact with the wall surface of the ring blank; the straight-wall mold includes a straight-wall main roll 3 and a straight-wall core roll 4. In the initial stage of overall rolling, the roll surface of the straight wall main roll 3 is in contact with the outer wall of the rolled part after partial rolling, and the roll surface of the straight wall core roll 4 is in contact with the outer wall of the unrolled part after partial rolling. The inner walls are in contact, which specifically includes the ...

Embodiment 1

[0045] In the segmental rolling method of a large high-temperature alloy high-cylindrical forging in this embodiment, the ring blank is first segmented and partially rolled by a segmented special-shaped die, and then the partially rolled ring is integrally rolled by a straight-walled die. Rolling, the segmented special-shaped mold includes a special-shaped main roll 1 and a special-shaped core roll 2, and the roll surfaces of the special-shaped main roll 1 and the special-shaped core roll 2 are in partial contact with the wall surface of the ring blank; the straight-wall mold includes a straight-wall The main roll 3 and the straight wall core roll 4, in the initial stage of overall rolling, the roll surface of the straight wall main roll 3 is in contact with the outer wall of the rolled part after partial rolling, and the straight wall core roll 4 The roller surface is in contact with the inner wall of the unrolled part after partial rolling, which specifically includes the fol...

Embodiment 2

[0057] In the segmental rolling method of a large high-temperature alloy high-cylindrical forging in this embodiment, the ring blank is first segmented and partially rolled by a segmented special-shaped die, and then the partially rolled ring is integrally rolled by a straight-walled die. Rolling, the segmented special-shaped mold includes a special-shaped main roll 1 and a special-shaped core roll 2, and the roll surfaces of the special-shaped main roll 1 and the special-shaped core roll 2 are in partial contact with the wall surface of the ring blank; the straight-wall mold includes a straight-wall The main roll 3 and the straight wall core roll 4, in the initial stage of overall rolling, the roll surface of the straight wall main roll 3 is in contact with the outer wall of the rolled part after partial rolling, and the straight wall core roll 4 The roller surface is in contact with the inner wall of the unrolled part after partial rolling, which specifically includes the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com