HDPE (high-density polyethylene) pipe and preparation method thereof

A technology for pipes and nano-calcium carbonate, which is applied in the field of polymers to achieve the effects of increasing tensile strength and elongation at break, enhancing tensile strength and elongation at break, and avoiding the decline in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

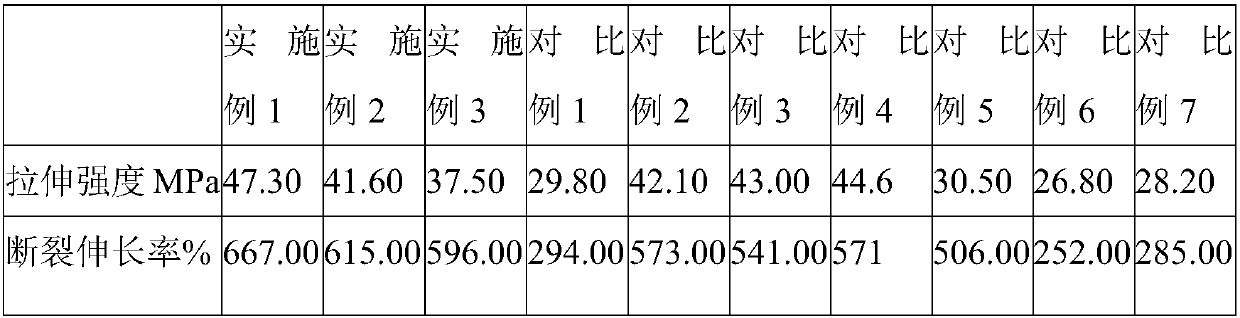

Examples

preparation example Construction

[0030] The preparation method of above-mentioned HDPE pipe, comprises the following steps:

[0031] (1) Prepare modified nano-calcium carbonate: mix and heat the nano-calcium carbonate of 20-50 mass parts and the water of 50-80 mass parts, form the mixture of nano-calcium carbonate and water, then add to described nano-calcium carbonate and water The coupling agent that adds 5-12 mass parts in the mixture is modified, makes modified nano-calcium carbonate;

[0032] (2) Preparation of organosilane-modified linear low-density polyethylene: melt organosilane and linear low-density polyethylene with a mass ratio of 1:10, and extrude and granulate at 100-120°C;

[0033] (3) Mix organosilane-modified linear low-density polyethylene, modified nano-calcium carbonate, HDPE, nano-calcium carbonate and lubricant to make granular mixture;

[0034] (4) mixing and melting the granular mixture with p-hydroxybenzoic acid and dibutyltin dilaurate and extruding through a mold to form the embry...

Embodiment 1

[0038]A kind of HDPE pipe material, with mass parts as unit, comprises following raw material: Modified nano-calcium carbonate is 10 mass parts, and HDPE is 68 mass parts, and nano-calcium carbonate is 25 mass parts, and paraffin is 3 mass parts, p-hydroxybenzoic acid 6.8 parts by mass, organosilane-modified linear low density polyethylene 6.8 parts by mass, and dibutyltin dilaurate 0.34 parts by mass.

[0039] The preparation method of above-mentioned HDPE pipe, comprises the following steps:

[0040] (1) Preparation of modified nano-calcium carbonate: the modified nano-calcium carbonate is to mix 36 mass parts of nano-calcium carbonate with 70 mass parts of water and heat to form a mixture of nano-calcium carbonate and water, and then to the nano-calcium carbonate Prepared by adding 8 parts by mass of coupling agent to the mixture of calcium carbonate and water for modification;

[0041] (2) Preparation of organosilane-modified linear low-density polyethylene: melt organosi...

Embodiment 2

[0046] A kind of HDPE pipe material, take mass part as unit, comprise following raw material: Modified nano-calcium carbonate is 2 mass parts, and HDPE is 70 mass parts, and nano-calcium carbonate is 20 mass parts, and paraffin is 6 mass parts, p-hydroxybenzoic acid 3.5 parts by mass, organosilane-modified linear low density polyethylene 10.5 parts by mass, and dibutyltin dilaurate 0.7 parts by mass.

[0047] The preparation method of above-mentioned HDPE pipe, comprises the following steps:

[0048] (1) described modified nano-calcium carbonate is that the nano-calcium carbonate of 20 mass parts is mixed with the water of 80 mass parts and heated, forms the mixture of nano-calcium carbonate and water, then in the mixture of described nano-calcium carbonate and water Prepared by adding 5 parts by mass of coupling agent for modification;

[0049] (2) Preparation of organosilane-modified linear low-density polyethylene: melt organosilane and linear low-density polyethylene with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com