Patents

Literature

456 results about "P-hydroxybenzoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

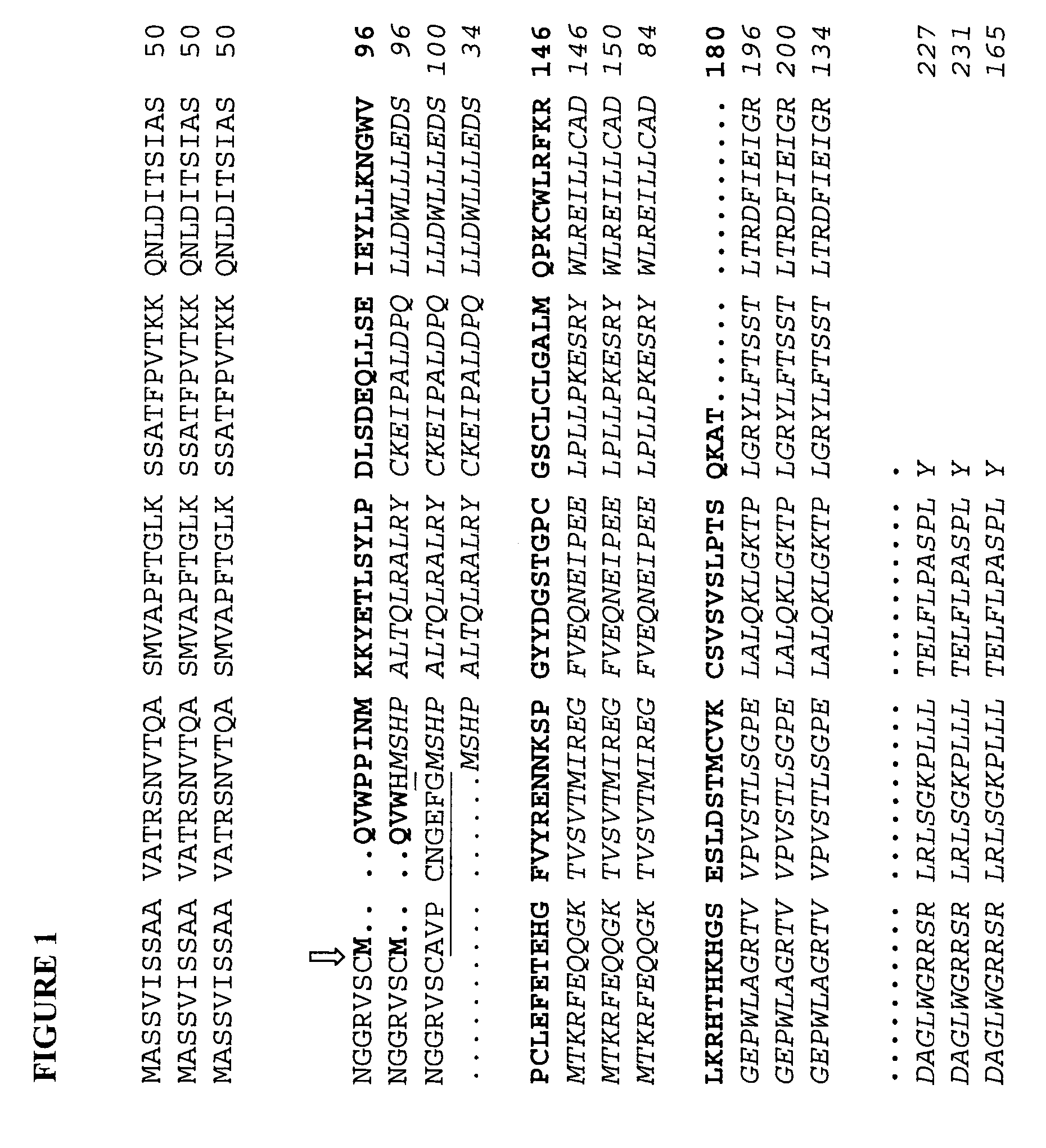

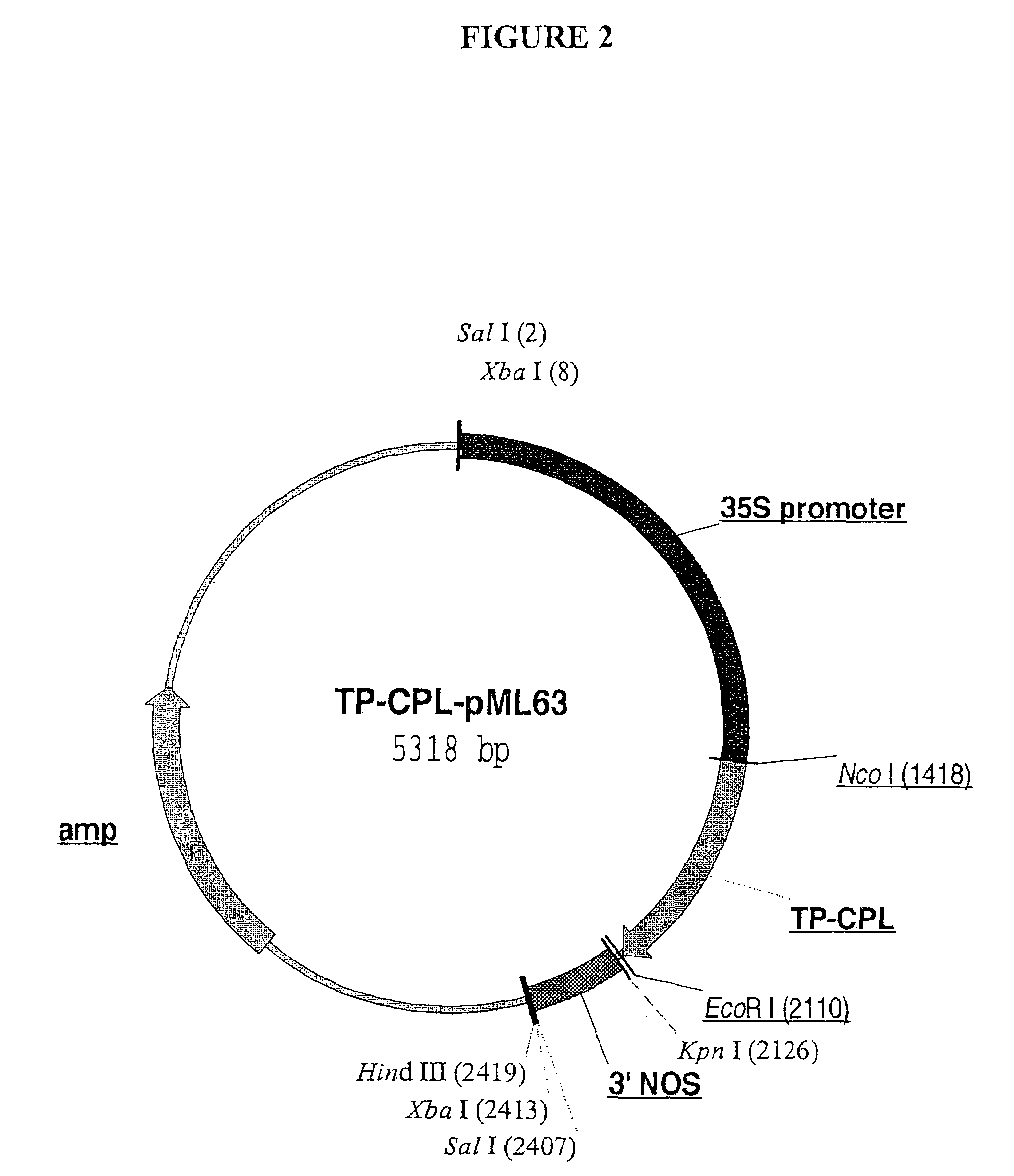

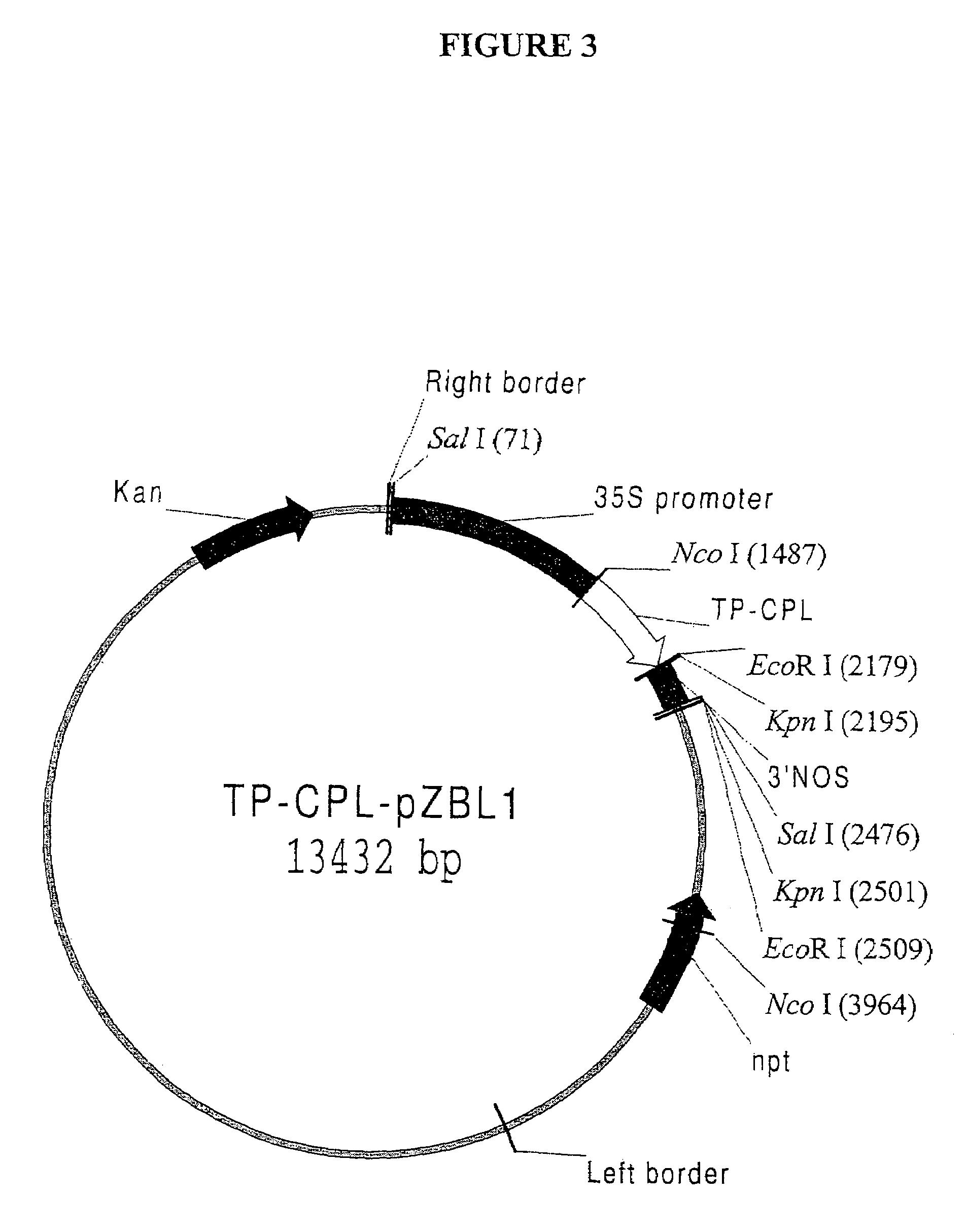

High level production of p-hydroxybenzoic acid in green plants

The invention relates to high-level production of pHBA in green plants using a unique expression cassette. The latter comprises a chorismate pyruvate lyase (CPL) coding sequence operably linked to a suitable promoter capable of driving protein expression in higher plants. Additionally, the CPL cassette comprises a sequence encoding a chloroplast transit peptide, its natural cleavage site, and a small portion of the transit peptide donor protein fused to the N-terminus of CPL. The chloroplast targeting sequence targets the foreign protein to the chloroplast compartment and aids in its uptake into the organelle. The cleavage site is unique to the transit peptide, and cleavage of the chimeric protein encoded by the cassette at this site releases a novel polypeptide that has full enzyme activity, comprising the mature CPL enzyme and a small portion of the transit peptide donor.

Owner:UNIVERSITY OF NORTH TEXAS

Quince preservative

InactiveCN101766217AReasonable formulaGood fresh-keeping effectFruit and vegetables preservationCelluloseThiophanate-methyl

The invention discloses a quince preservative which is prepared by mixing cellulose, thiophanate methyl, carbendazim, p-hydroxybenzoic acid, vitamin C, maleic hydrazide and water. The invention has reasonable prescription, good preservation effect and low production cost. When in use, fruits are put in the preservative for 1 to 2 minutes.

Owner:蒋娟

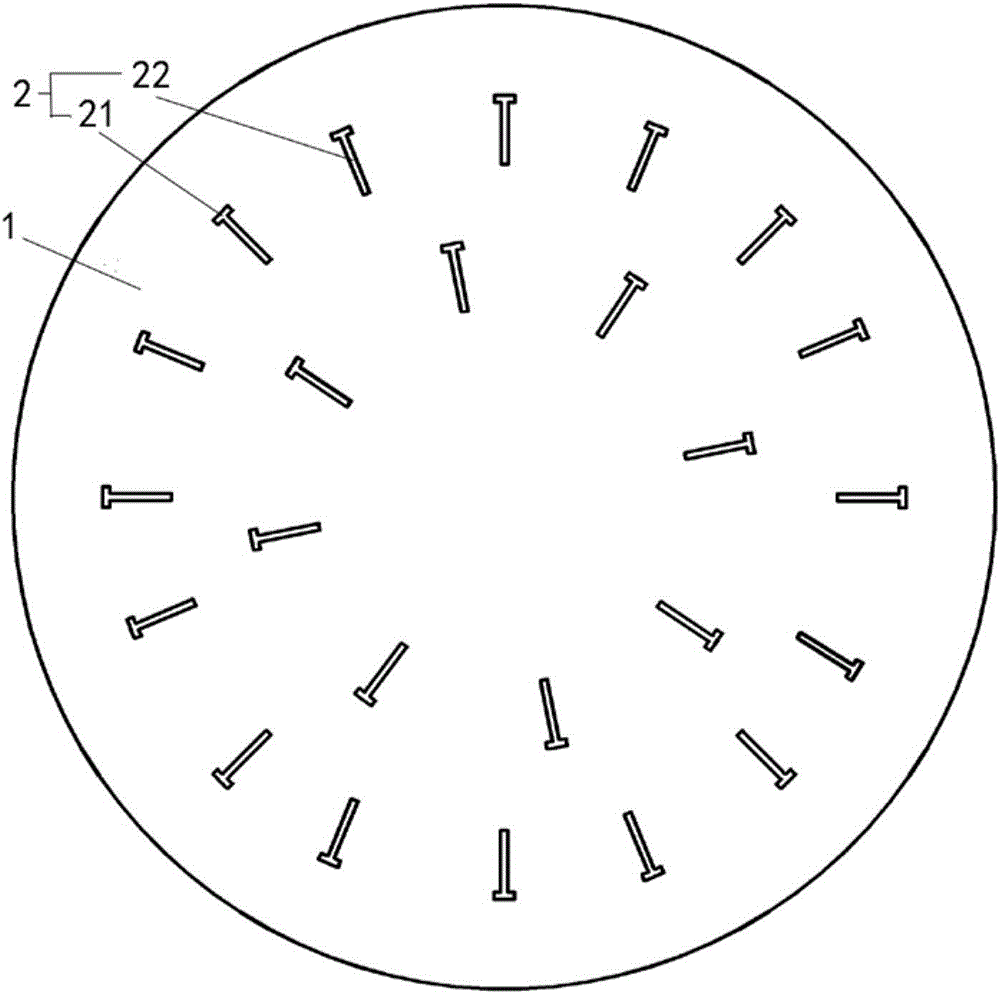

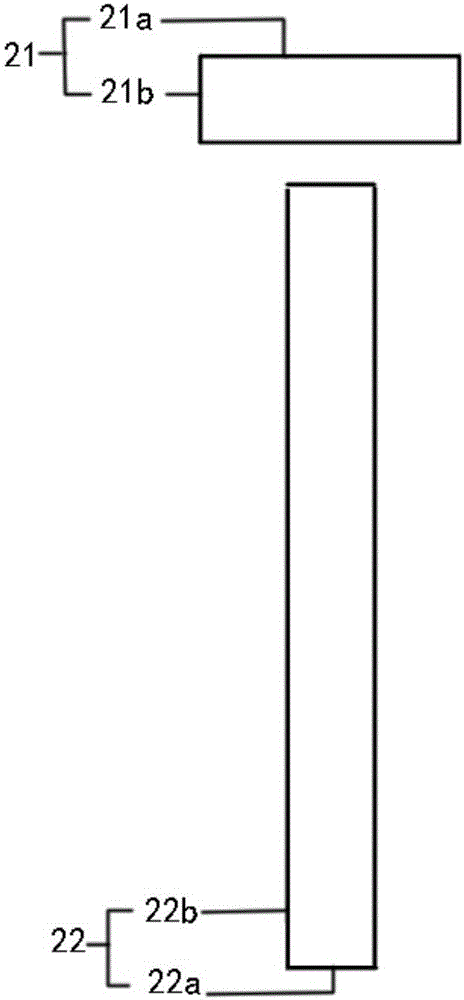

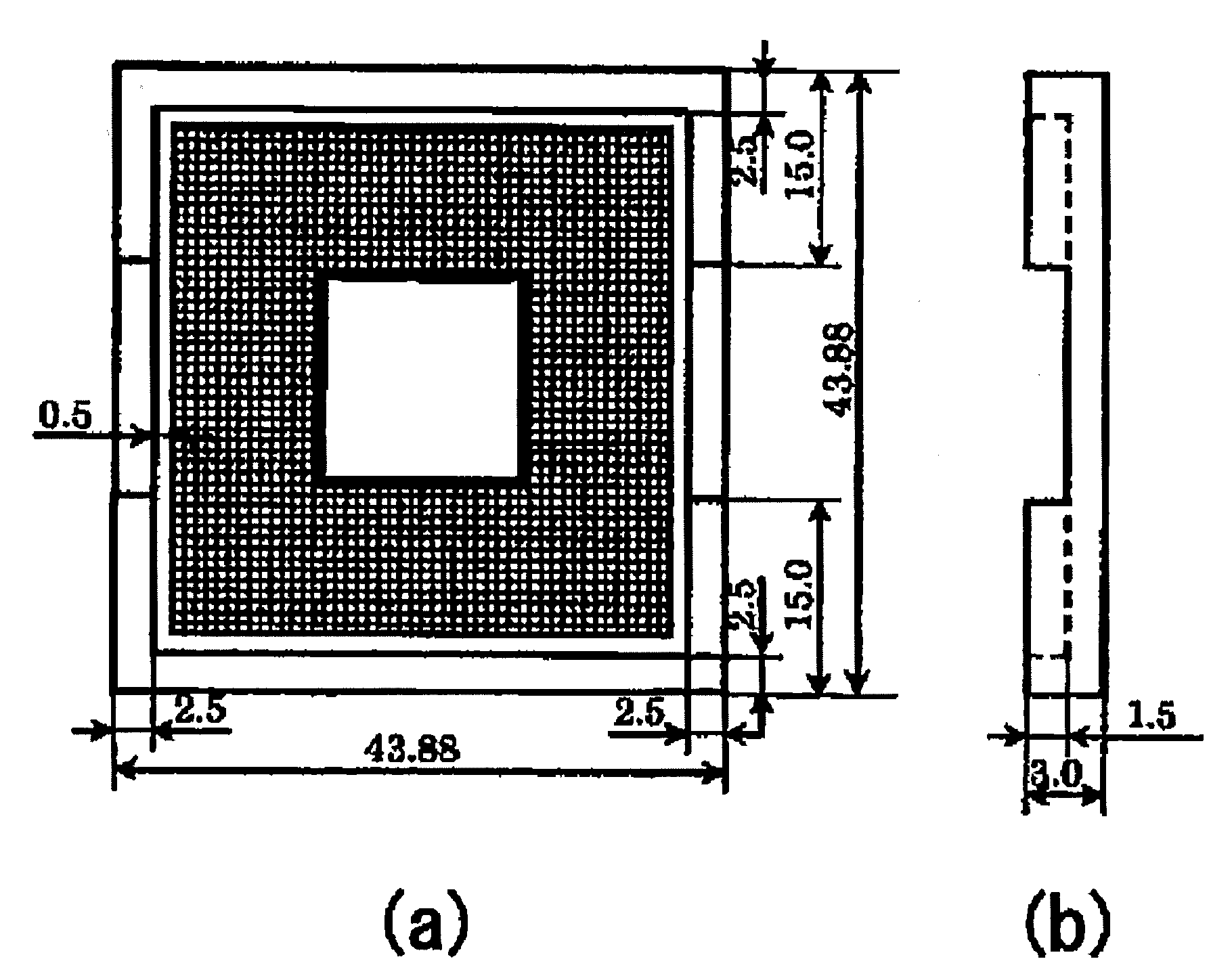

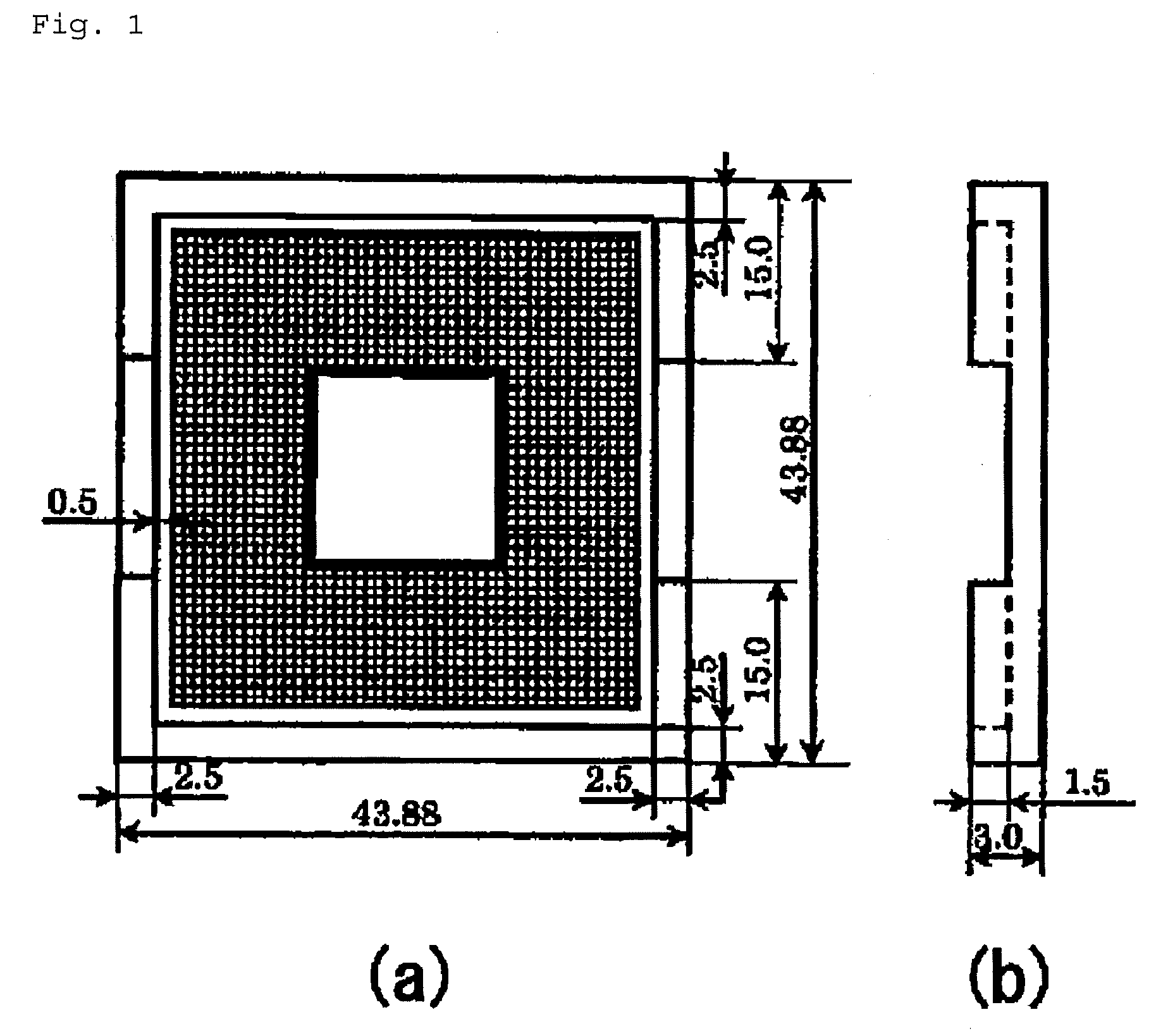

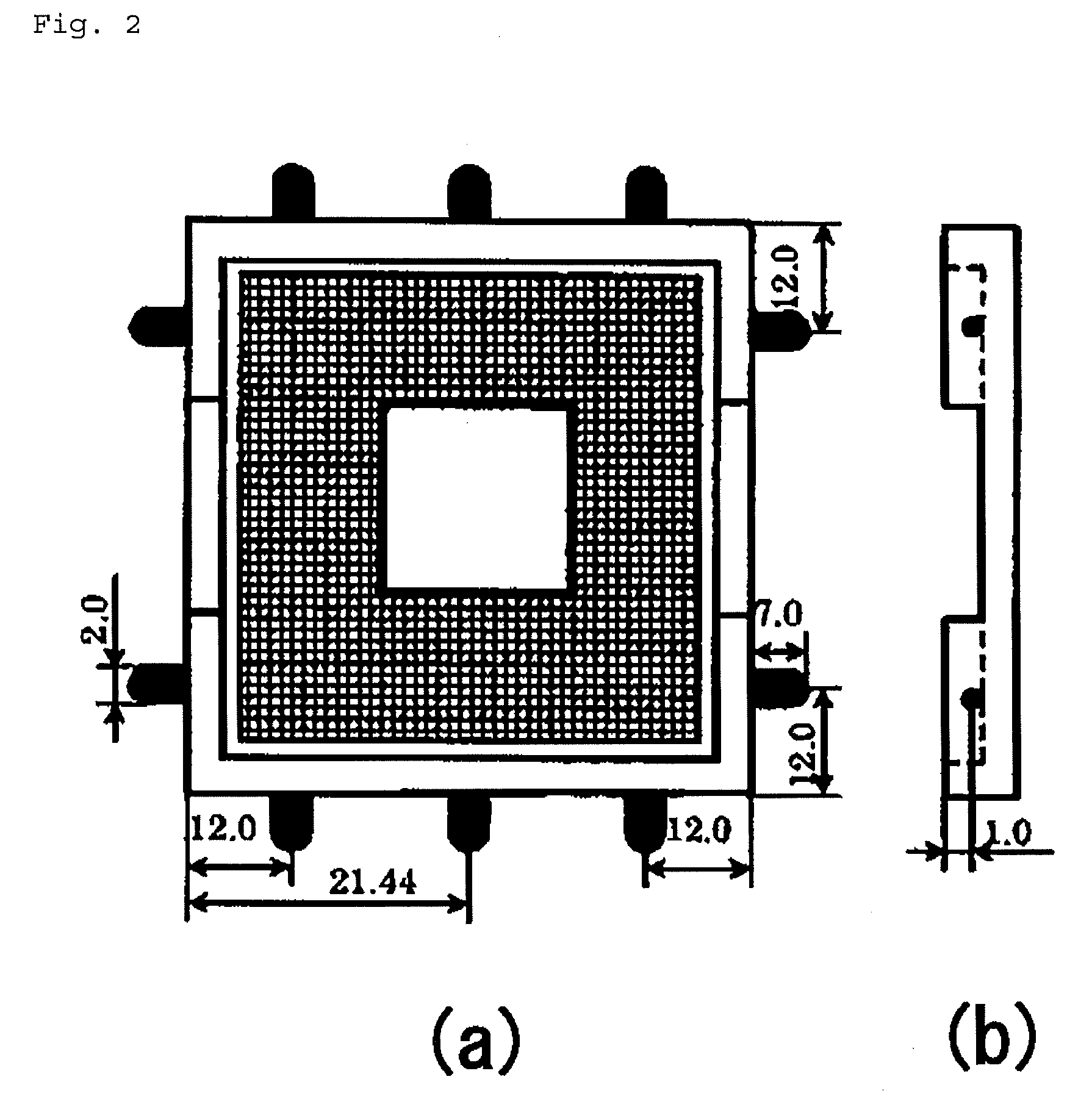

Planar connector

InactiveUS8272879B2Excellent performance balanceImprove performanceLiquid crystal compositionsPlastic/resin/waxes insulatorsLiquid crystallineBenzoic acid

The present invention provides a planar connector having excellent performances including flatness, warp-deformation resistance, and heat resistance, being capable of responding to shape changes in recent planar connectors. Specifically, the planar connector is composed of a composite resin composition comprises (A) a liquid crystalline polymer containing 55% by mole or less of p-hydroxy benzoic acid residue and having a melting point of 330° C. or higher, (B) a plate-like inorganic filler, and (C) a fibrous filler having a weight average fiber length within a range of 250 to 600 μm, the amount of (B) component being 25 to 35% by weight to the total composition, the amount of (C) component being 10 to 25% by weight to the total composition, the sum in total of (B) component and (C) component being 40 to 50% by weight to the total composition, wherein the connector has a lattice structure inside an outer frame, and has an opening inside the lattice area, and wherein the pitch interval of the lattice area is 1.5 mm or less, and the ratio of the thickness of the thickness of the lattice area to the outer frame area is 0.8 or less.

Owner:POLYPLASTICS CO LTD

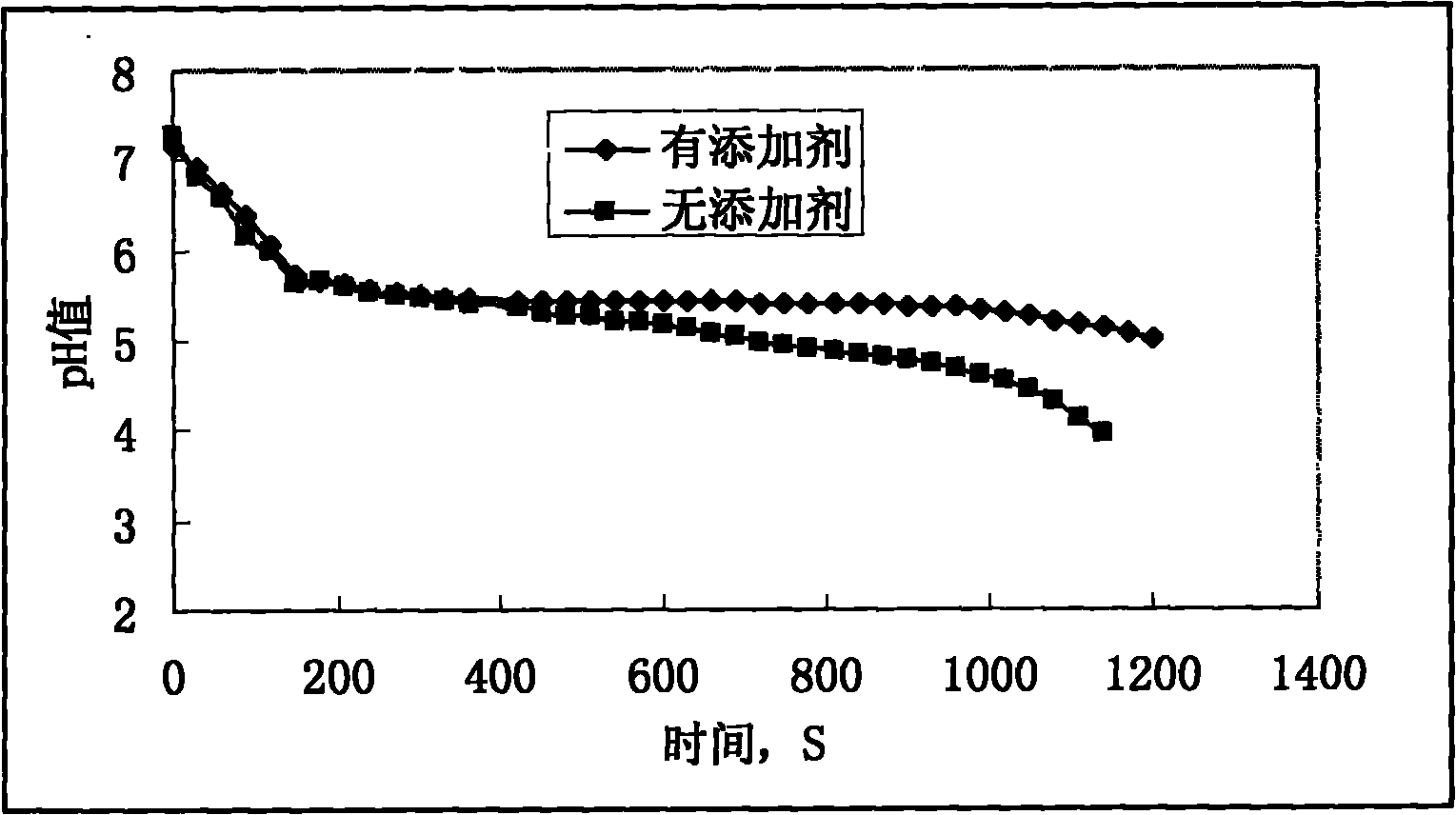

Multifunctional composite additive for wet-method flue gas desulfuration process and using method thereof

InactiveCN102019138AImprove solubilityFacilitate absorption reactionDispersed particle separationDissolutionSlurry

The invention belongs to the technical field of a limestone-gypsum wet-method flue gas desulfuration process and relates to a multifunctional composite additive for a wet-method flue gas desulfuration process and a using method thereof. The composite additive comprises the following components in percentage by mass: 31 to 45 percent of nylon acid, 31 to 45 percent of sodium humate, 6 to 9 percentof organic silicon defoaming agent, 2 to 5 percent of potassium formate, 2 to 5 percent of manganese sulfate and 2 to 5 percent of p-hydroxybenzoic acid. The composite additive can promote the dissolution of the limestone and reduce the using amount of the limestone, has an enhancement factor for improving an absorption reaction of sulfur dioxide (SO2), accelerates the migration speed of SO2 gas liquid, promotes the adsorption reaction of the SO2 in a liquid membrane, inhibits the soft scales of calcium sulfate (CaSO3) from generating, improves the pH value buffer capacity of limestone slurry, slows down the reducing speed of the pH value in the process of absorbing the SO2 by the desulfuration slurry continuously, and achieves the effect of avoiding bubbling and overflow of the desulfuration slurry.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

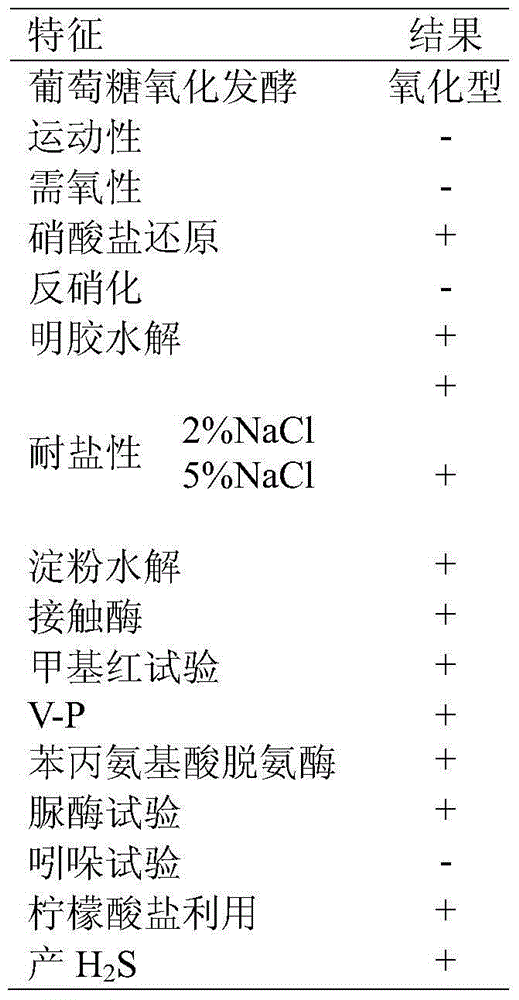

Pseudomonas aeruginosa strain separating, purifying and domesticating method and use

The invention discloses a Pseudomonas aeruginosa strain TBPY, which is screened from tribromophenol(TBP)-polluted sludge and purified. The purified strain is domesticated by a pressure type domesticating method with gradually increased TBP concentration in an organic salt culture medium, and the domesticated strain can be used for the biological control of waste water containing persistent organic pollutants such as phenol, pyrocatechol, resorcinol, benzoic acid, p-hydroxybenzoic acid, vanillin, 4-chlorophenol, 2,4-dichlorophenol, trichlorophenol and tribromophenol and has high research and application values.

Owner:HEFEI UNIV OF TECH

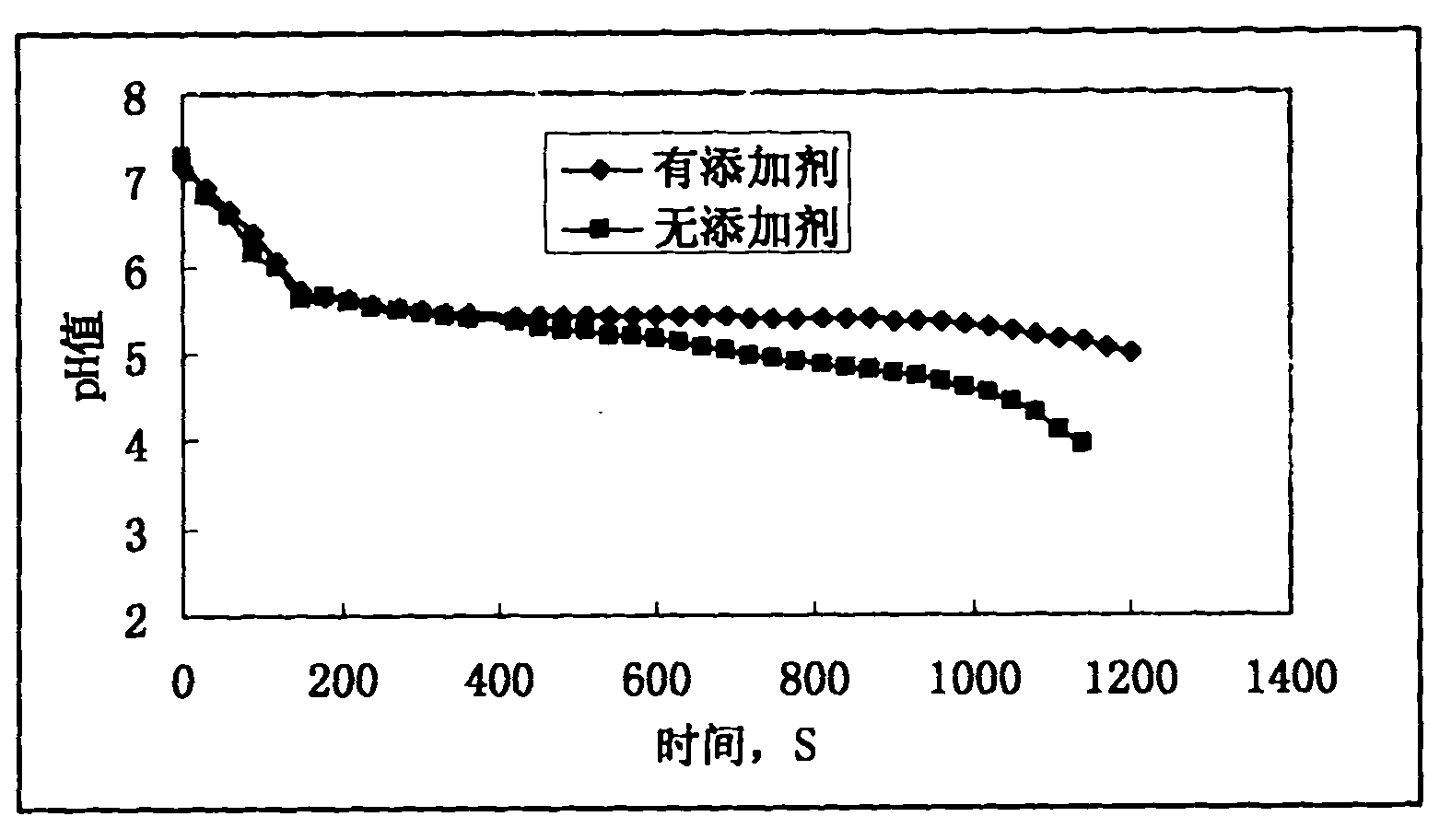

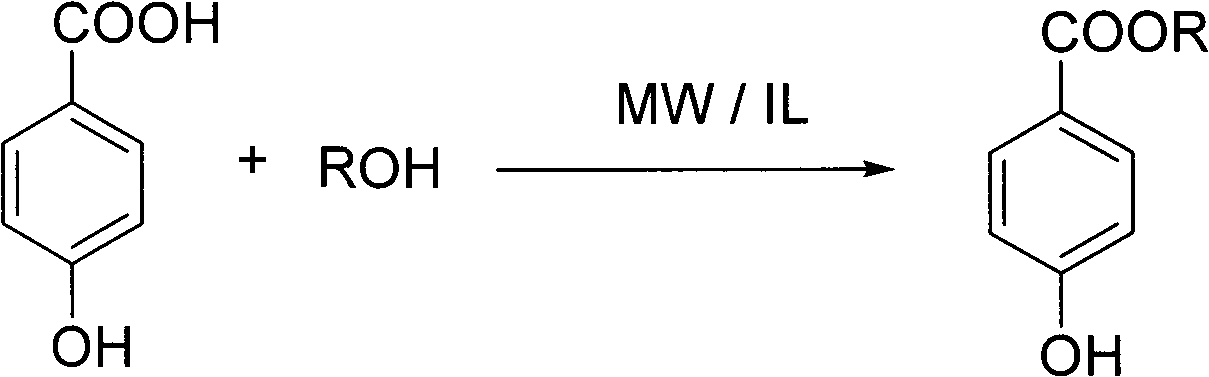

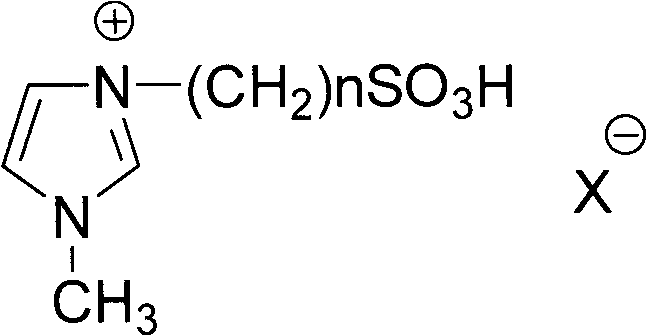

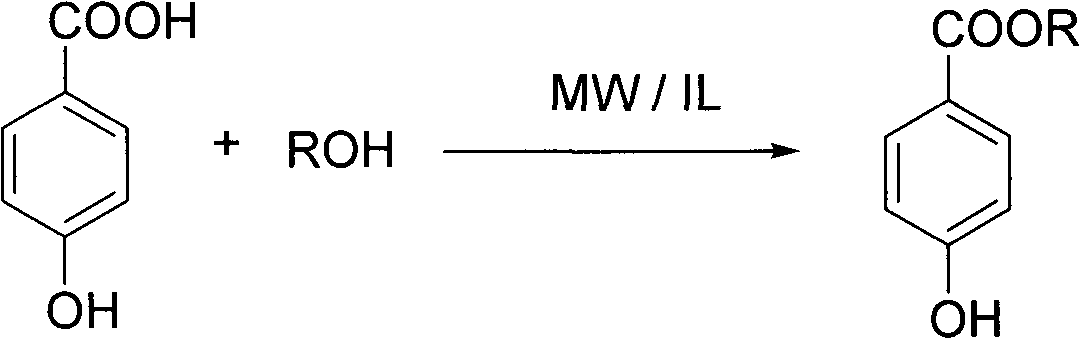

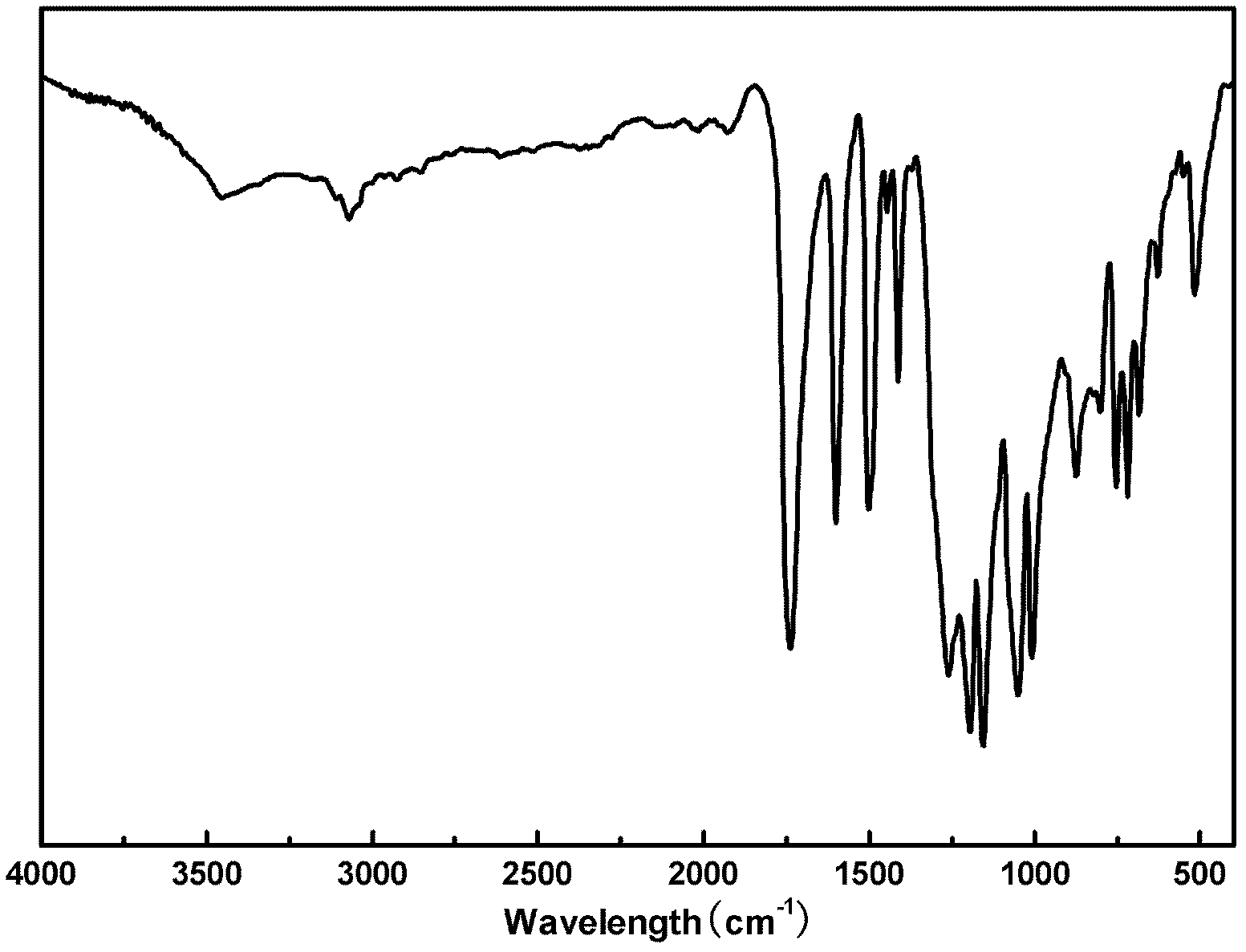

Preparation method of nipagin ester compound under promotion of sulfonic acidic ionic liquid

InactiveCN101982453AMild reaction conditionsAvoid corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium bicarbonateStrong acids

The invention provides a preparation method of a nipagin ester compound under promotion of sulfonic acidic ionic liquid. The method comprises the following steps: taking the sulfonic acidic ionic liquid as a reaction solvent and a promoter, and carrying out esterification on p-hydroxybenzoic acid and corresponding alcohol at the temperature of 80-120 DEG C for 0.5-3h under a microwave radiation condition to obtain a coarse product of nipagin ester; adding water to the coarse product, and repeatedly extracting the product and impurities such as unreacted raw materials and the like with diethylether until a diethyl ether phase is non-fluorescent; merging the diethyl ether phase, sequentially washing with saturated sodium bicarbonate aqueous solution and saturated salt solution and drying with anhydrous sodium sulfate; removing the solvent through vacuum evaporation to obtain the nipagin ester product; and removing a large quantity of water from an aqueous phase by rotary evaporation, and drying with salicylic acid in vacuum to obtain the recovered ionic liquid which can be recycled. The preparation method has the advantages of mild reaction condition, simple batch feeding and aftertreatment, short reaction time, and high mole yield of the obtained finished product of the nipagin ester which is over 85%, and being capable of avoiding equipment corrosion and pollution caused by using strong acid.

Owner:SHANDONG UNIV +1

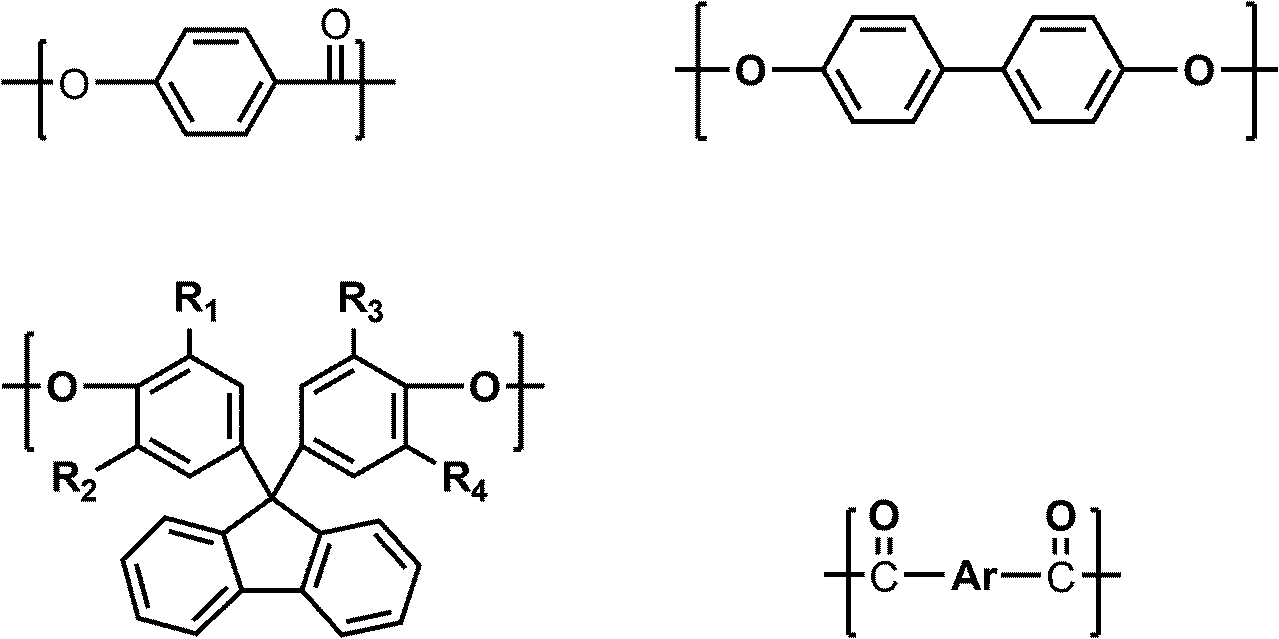

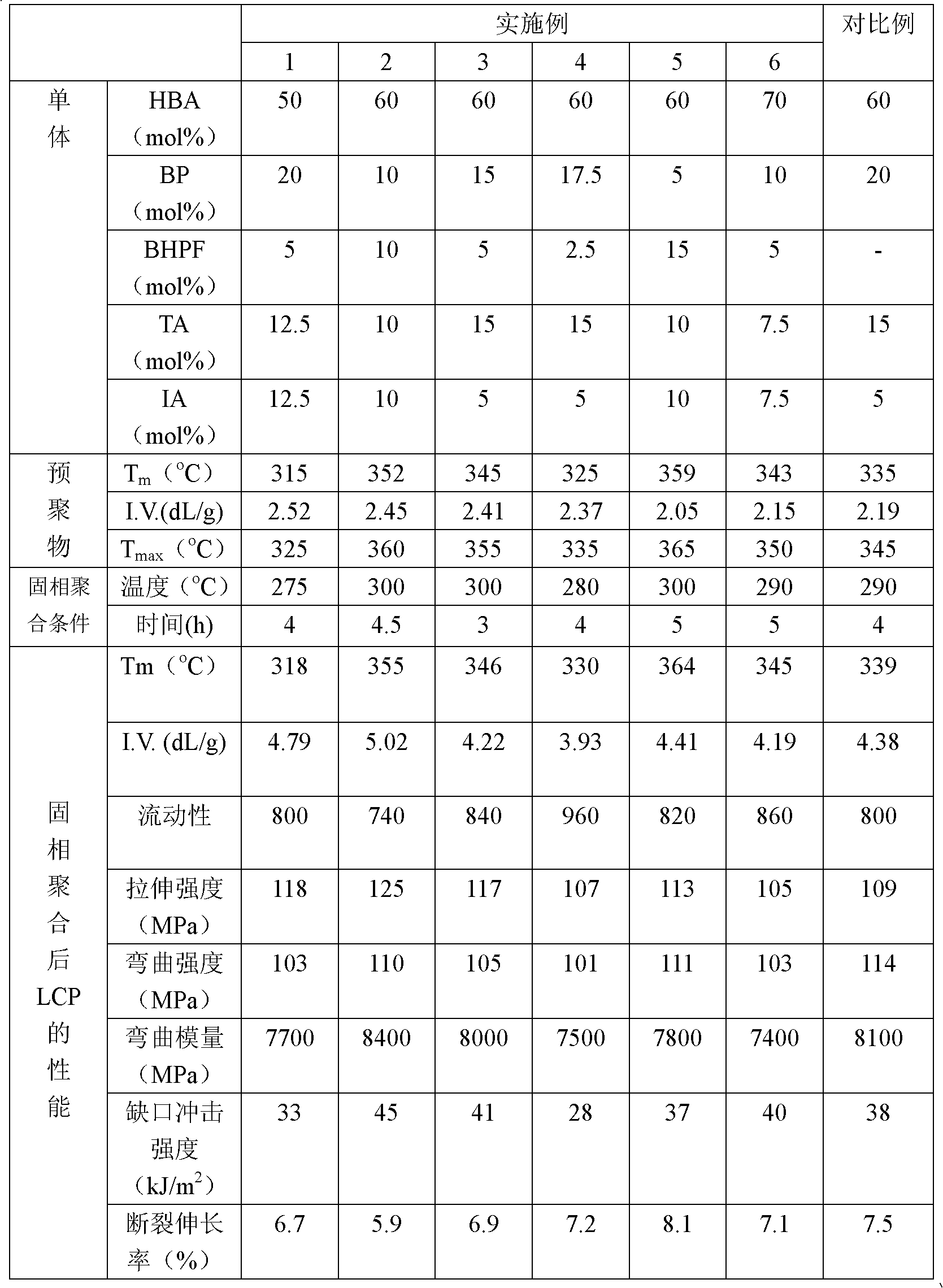

Liquid crystal polyester and its preparation method and use

ActiveCN103012759AImprove liquidityEasy to processLiquid crystal compositionsPolyesterChain structure

The invention belongs to the field of material engineering and discloses a liquid crystal polyester and its preparation method and use. The liquid crystal polyester is obtained by a condensation polymerization reaction of p-hydroxybenzoic acid, biphenol, diphenol with a fluorene skeleton and aromatic dicarboxylic acid. A unit with a fluorene skeleton side group is introduced into a chain structure of the liquid crystal polyester so that the liquid crystal polyester has a melting temperature of 310 to 360 DEG C, good fluidity and excellent melting processing performances.

Owner:KINGFA SCI & TECH CO LTD +2

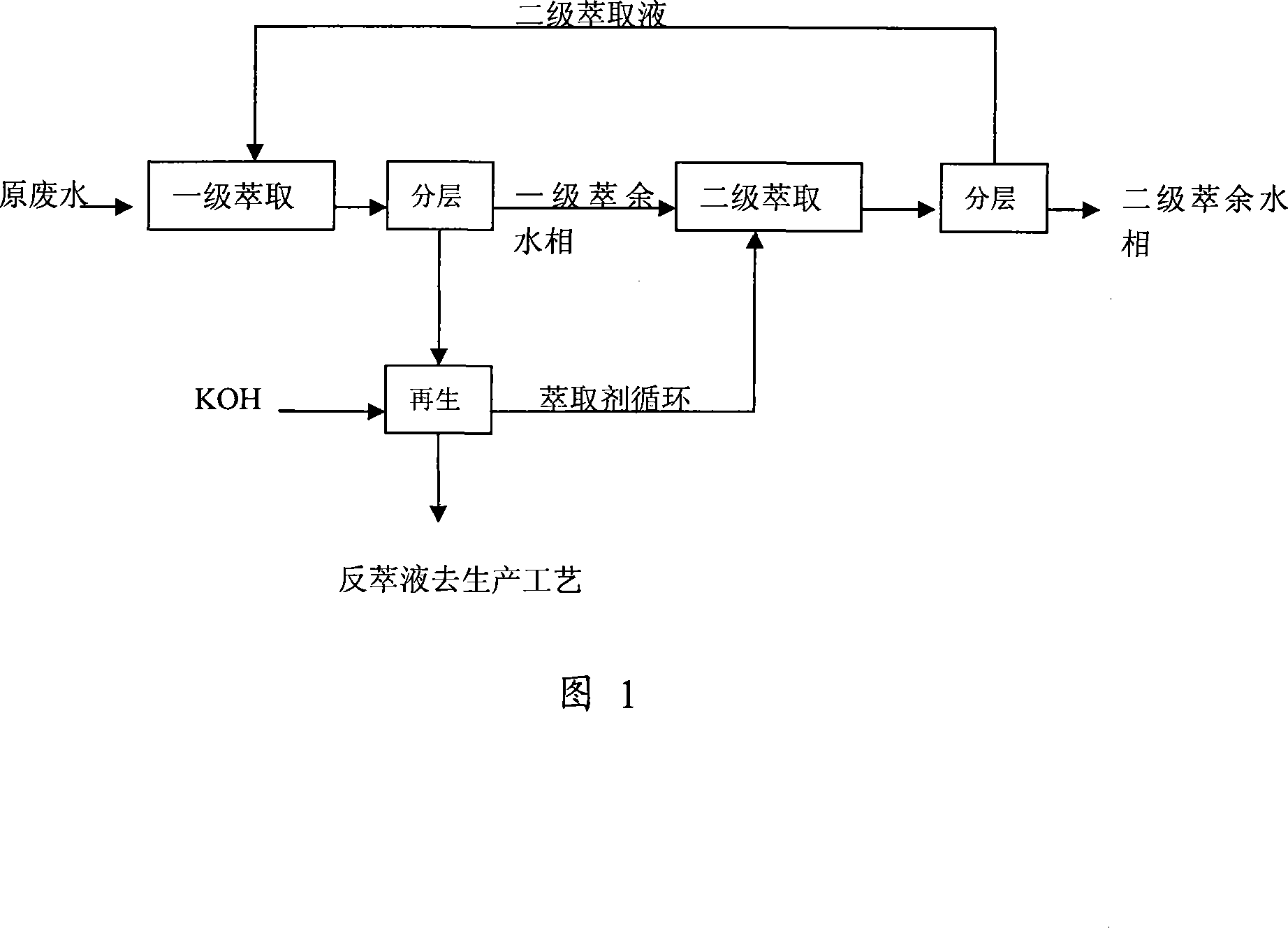

Method for reclaiming and treating phenol and p-hydroxybenzoic acid in p-hydroxybenzoic acid technique waste water

InactiveCN101239904AHigh recovery rateLow running costOrganic compound preparationChemical recyclingPhosphatePotassium hydroxide

Disclosed is a method for recoverying and treating phenol and p-hydroxybenzoate in p-hydroxybenzoate process wastewater, comprising: extracting the p-hydroxybenzoate process wastewater by an extractant, at the same time, recoverying phenol and p-hydroxybenzoate in the wastewater; the extractant is trioctylamine, tri-butyl-phosphate, xylene or n-octanol, or two or more mixtures selected therefrom; the extraction liquid is antiextracted by alkali matter solution, wherein the alkali matter is selected from: potassium hydroxide, sodium hydroxide or ammonia hydroxide; the antiextraction liquid is back to the production process to perform carboxylation. A preferable scheme is two-step refluence extraction; second extraction is performed on the extraction remaining aqueous phase, which is performed with first extraction, by a regeneration extractant after first extraction; the second extraction liquid is back to the first extraction step, and the original wastewater is performed with first extraction. The invention has obvious economical and environmental benefit, the recovery rate of phenol and p-hydroxybenzoate in the wastewater is about 100%, and the COD removing rate is 98.9%.

Owner:NANJING NORMAL UNIVERSITY

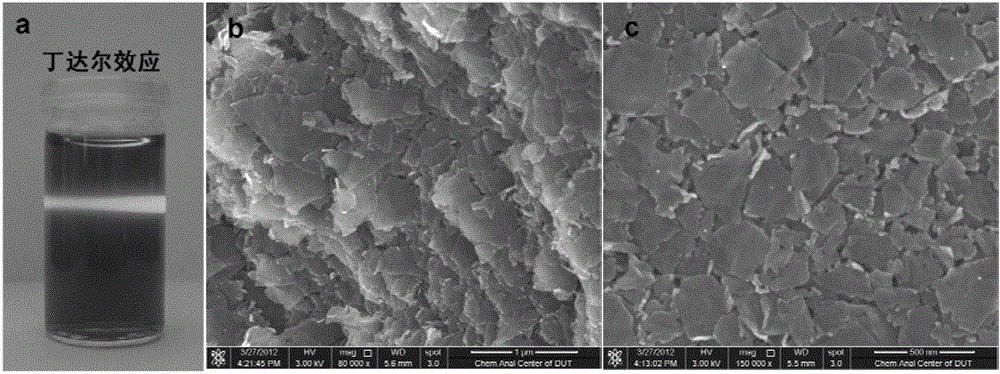

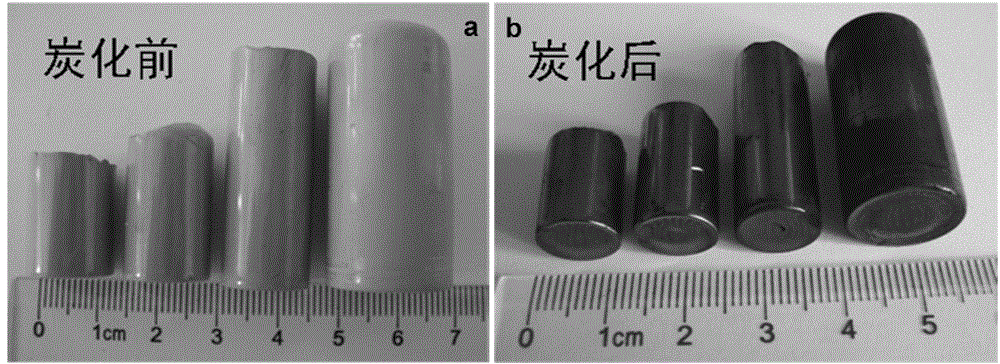

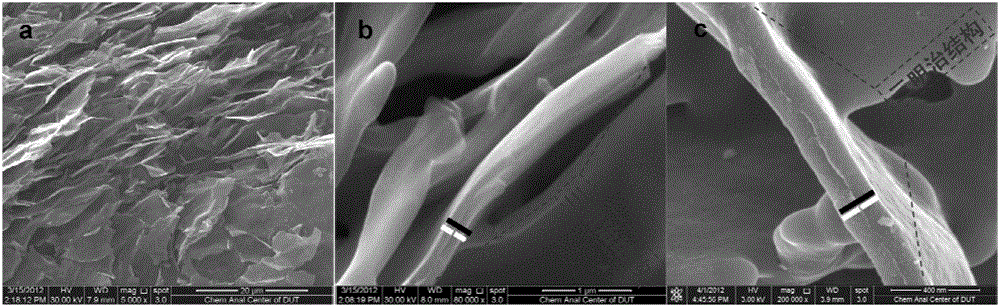

Porous carbon with high-volumetric-specific-capacitance composite graphene, preparation method thereof, and application thereof

ActiveCN102745666ANovel structureSimple processGrapheneCarbon preparation/purificationCapacitancePorous carbon

The invention relates to porous carbon with high-volumetric-specific-capacitance composite graphene, a preparation method thereof, and an application thereof. The porous carbon comprises the raw materials of graphene oxide, hydroxyl-containing phenols and derivatives thereof (phenol, resorcinol, phloroglucin, p-hydroxybenzoic acid, or 2,4-dihydroxybenzoic acid), and aldehydes (formaldehyde, butyraldehyde, or terephthalaldehyde). A carboxyl-containing compound (amphoteric compound amino acid, malonic acid, or oxalic acid) is used for regulating the pH value of the system and for initiating a phenolic condensation polymerization reaction, such that a sandwich structure with nano-sheets embedded in a polymer is prepared. The structure is subjected to carbonization, and the porous carbon is prepared with a one-step method. The prepared porous carbon with the sandwich structure is advantaged in novel structure, simple preparation technology, high product purity, convenient application, and suitability for large-scale productions. The porous carbon shows a mass specific capacitance similar to that of a graphene-based material in the application in a super-capacitor. Also, the volumetric specific capacitance of the porous carbon is higher by a magnitude than that of the graphene-based material. Therefore, the porous carbon has great application potential and market prospect.

Owner:DALIAN UNIV OF TECH

Environment-friendly high-strength water-resisting and mildew-resisting adhesive for plywood and preparation method of environment-friendly high-strength water-resisting and mildew-resisting adhesive

InactiveCN105542683AReduced effectReduce hydrogen bondingNon-macromolecular adhesive additivesStarch adhesivesBond ForceP-hydroxybenzoic acid

The invention discloses an environment-friendly high-strength water-resisting and mildew-resisting adhesive for a plywood and a preparation method of the environment-friendly high-strength water-resisting and mildew-resisting adhesive. The environment-friendly high-strength water-resisting and mildew-resisting adhesive is prepared from the following raw materials including polyvinyl alcohol, cassava starch, dibutyl phthalate, sodium pyrosulfite, tannic acid, jade powder, calcium silicate hydrate, asbestos powder, p-hydroxybenzoic acid hydrazide, diammonium hydrogen phosphate, hydroquinone, sodium diethylhexyl sulfosuccinate, triethyltin chloride, phenyl mercury oleate, borax and the like. The polyvinyl alcohol and the cassava starch are subjected to a cross-linking reaction so that crystallization degrees of the polyvinyl alcohol and the cassava starch are reduced and a new cross-linking structure is formed, and furthermore, the thermal stability of the adhesive is improved; the borax is added and the polyvinyl alcohol and the starch can be subjected to further cross linking, so that the cross-linking degree and the initial viscosity of the adhesive are improved, and furthermore, the water resistance and the bonding force of the adhesive can be improved; the triethyltin chloride, the phenyl mercury oleate, the p-hydroxybenzoic acid hydrazide and the like are added so that the mildew-resisting capability of the plywood can be improved.

Owner:倪协照

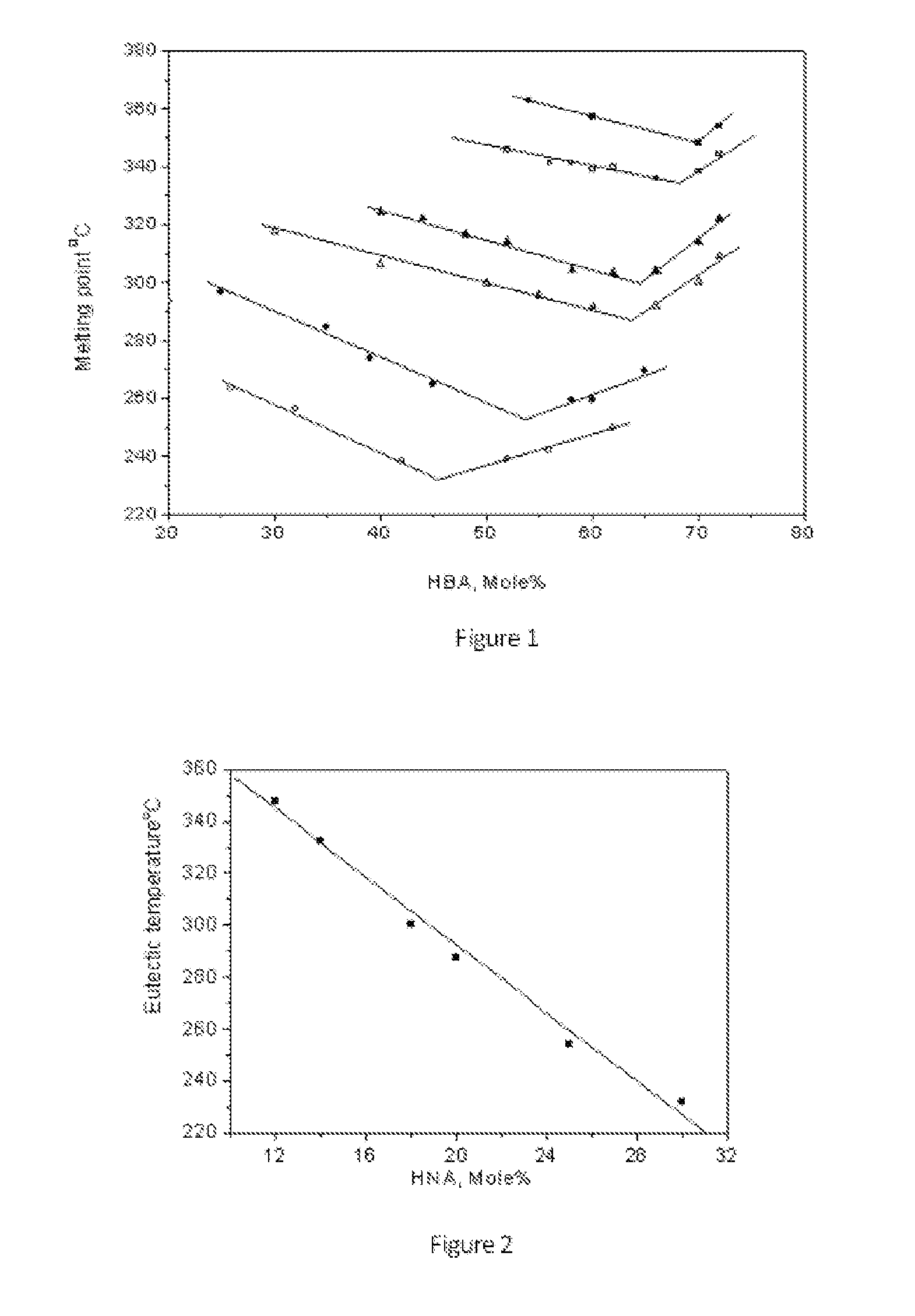

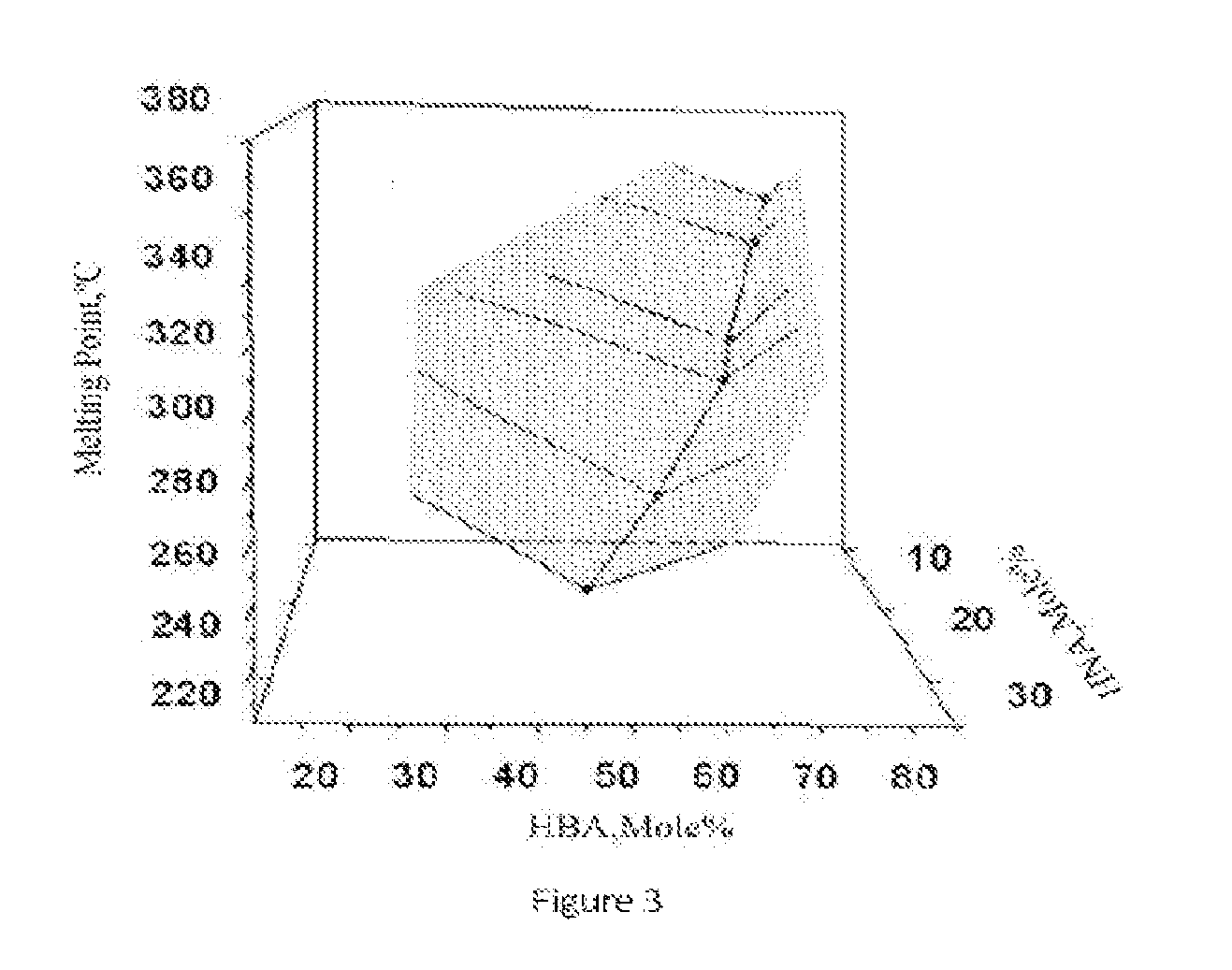

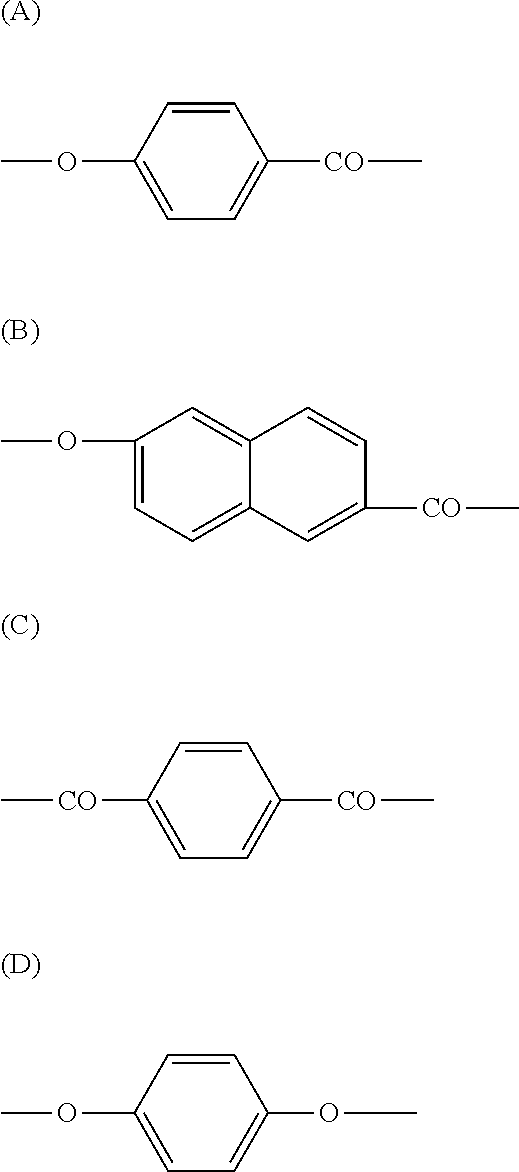

Liquid crystalline polyester compositions

ActiveUS20110233462A1High molar massHigh melting pointLiquid crystal compositionsLiquid crystallineTerephthalic acid

The present invention provides a class of thermotropic liquid crystalline polyesters (TLCPs) and molding compositions comprising the polyesters and glass fiber. The TLCPs consist essentially of repeat units derived from p-hydroxybenzoic acid (HBA), 6-hydroxy-2-naphthoic acid (HNA), terephthalic acid (TA), and hydroquinone (HQ), and the mole percent of HBA, HNA, TA and HQ is 34-72%, 12-26%, 4-21% and 4-21%, respectively. The TLCPs have a melting temperature equal to or below 355° C., an inherent viscosity of 4.0-10.0 dL / g and a Heat Deflection Temperature (HDT) in the range of 260-285° C. when compounded with 30% by weight glass fiber. The optimum compositions, selected from the above-mentioned compositional ranges exhibit a relatively low melting temperature and a relatively high HDT. Specified compositions, selected from the above-mentioned compositional ranges have low melting point, which are useful to blend with conventional polymers such as poly (ethylene terephthalate) and nylon etc.

Owner:WANG XIUZHEN +2

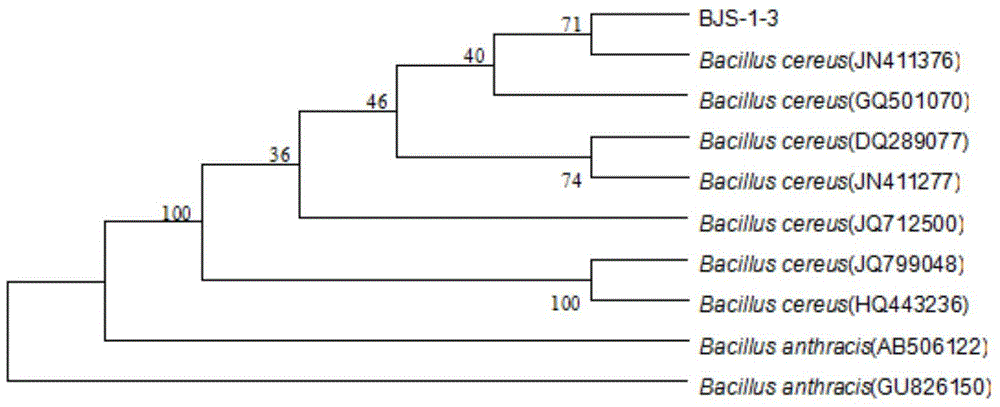

Phenolic acid type allelochemical degrading bacterium and preparation and application of microbial inoculum thereof

ActiveCN104099272ANormal growthEfficient degradation abilityBacteriaMicroorganism based processesBenzoic acidMicrobiology

The invention relates to a phenolic acid type allelochemical degrading bacterium and the preparation and the application of a microbial inoculum thereof. The BJS-1-3 bacterial strain disclosed by the invention is from rhizosphere soil of perennial poplars in Tai'an City, Shandong Province, China, and the soil is artificially gathered, screened and purified to obtain the bacterial strain. The bacterial strain has a high degrading capacity to benzoic acid, and phenolic acid type allelochemicals, such as ferulic acid, p-hydroxybenzoic acid, vanillin, cinnamic acid and phloridzin, can be respectively used as a unique carbon source in which the bacterial strain grows and propagates, and the bacterial strain can stably propagate in the rhizosphere of poplars, apple trees and cucumber plants. Through the adoption of the microbial inoculum prepared from the bacterial strain, the succession cropping obstacles of plants, such as the poplars, the apple trees and the cucumber plants, due to the accumulation of phenolic acid type allelochemicals can be effectively prevented and treated. The preparation technology of the microbial inoculum is simple, the fermentation period is short, the cost is low, and the industrialized production is facilitated.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

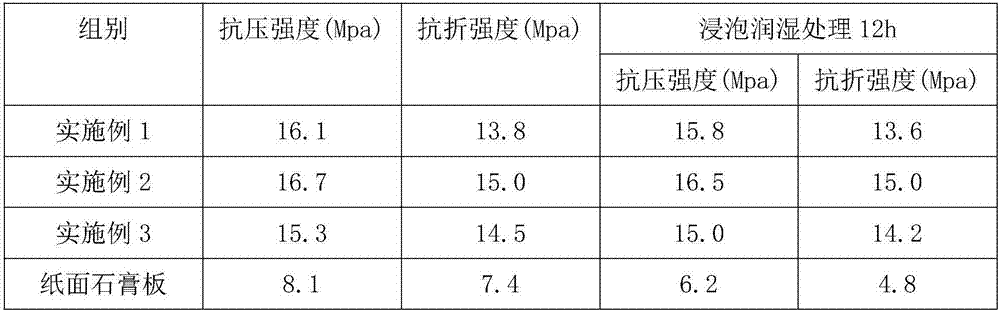

High-strength gypsum board and preparation method thereof

The invention discloses a high-strength gypsum board and a preparation method thereof, and relates to the technical field of novel building materials. The high-strength gypsum board comprises the following raw materials: modified gypsum powder, Zuoyun clay, anorthite powder, nano tourmaline powder, coarse whiting powder, borax, a silicon carbide fiber, p-hydroxybenzoic acid isopropyl ester, an organic silicon emulsion, a coupling agent, an anti-mold agent, a defoaming agent and an adhesive. The preparation method comprises the following steps: mixing raw materials, aging, performing injection molding, performing natural maintenance, demolding, drying, and shaping, thereby obtaining the high-strength gypsum board. The high-strength gypsum board is simple to prepare, and low in cost; and the problem that the conventional gypsum board is low in mechanical strength is solved, that is, the strength of the gypsum board is not greatly affected or even degraded even when the gypsum board is used in moisture and wet environments for a long time, so that the high-strength gypsum board is long in service life, safe, reliable and wide in market prospect.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

High temperature resistant anticorrosive paint comprising polyaryl organic silicon resin

The invention discloses a high temperature resistant anticorrosive paint comprising polyaryl organic silicon resin. The high temperature resistant anticorrosive paint comprises the following components according to weight ratio: 40-50 parts of polyaryl organic silicon resin, 20-30 parts of p-hydroxybenzoic acid glycidyl ester, 5-10 parts of acrylic resin, 10-15 parts of mica powder, 10-15 parts of graphene, 5-10 parts of acetic ether and 10-20 parts of diluent, wherein the diluent is butanol or xylene. The high temperature resistant anticorrosive paint can resist temperature of 400-500 DEG C, and has a good anticorrosion effect.

Owner:SUZHOU AITESI FURTHER MATERIALS CO LTD

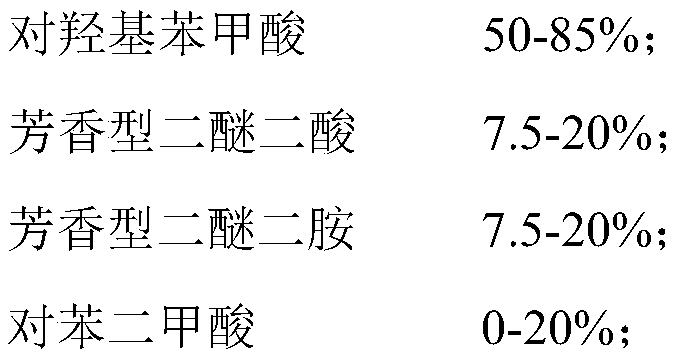

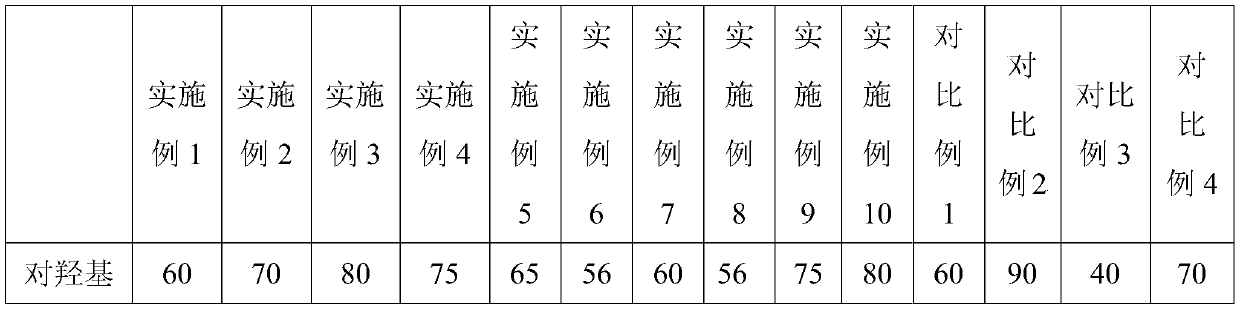

Novel thermotropic liquid crystal polymer and preparation method thereof

The invention discloses a thermotropic liquid crystal polymer. The polymer is characterized by comprising the following components, in percentages by molar: 50-85% of p-hydroxybenzoic acid, 7.5-20% ofaromatic diether diacid, 7.5-20% of aromatic diether diamine, and 0-20% of terephthalic acid, wherein a ratio of a mole number of the aromatic diether diamine to a sum of mole numbers of the aromaticdiether diacid and terephthalic acid is 1.2:1 to 1:1.2. According to the polymer provided by the invention, an aromatic ether-containing functional group is introduced into a traditional thermoplastic aromatic polyester molecular chain, the self-prepared functional aromatic diether diacid is utilized to replace a traditional diacid monomer having a meta-benzene structure, the functional aromaticdiether diamine is utilized to replace a traditional hydroquinone monomer, and the thermotropic liquid crystal polymer with good mechanical properties is prepared; and the application field is broadened while the costs are reduced.

Owner:珠海派锐尔新材料有限公司

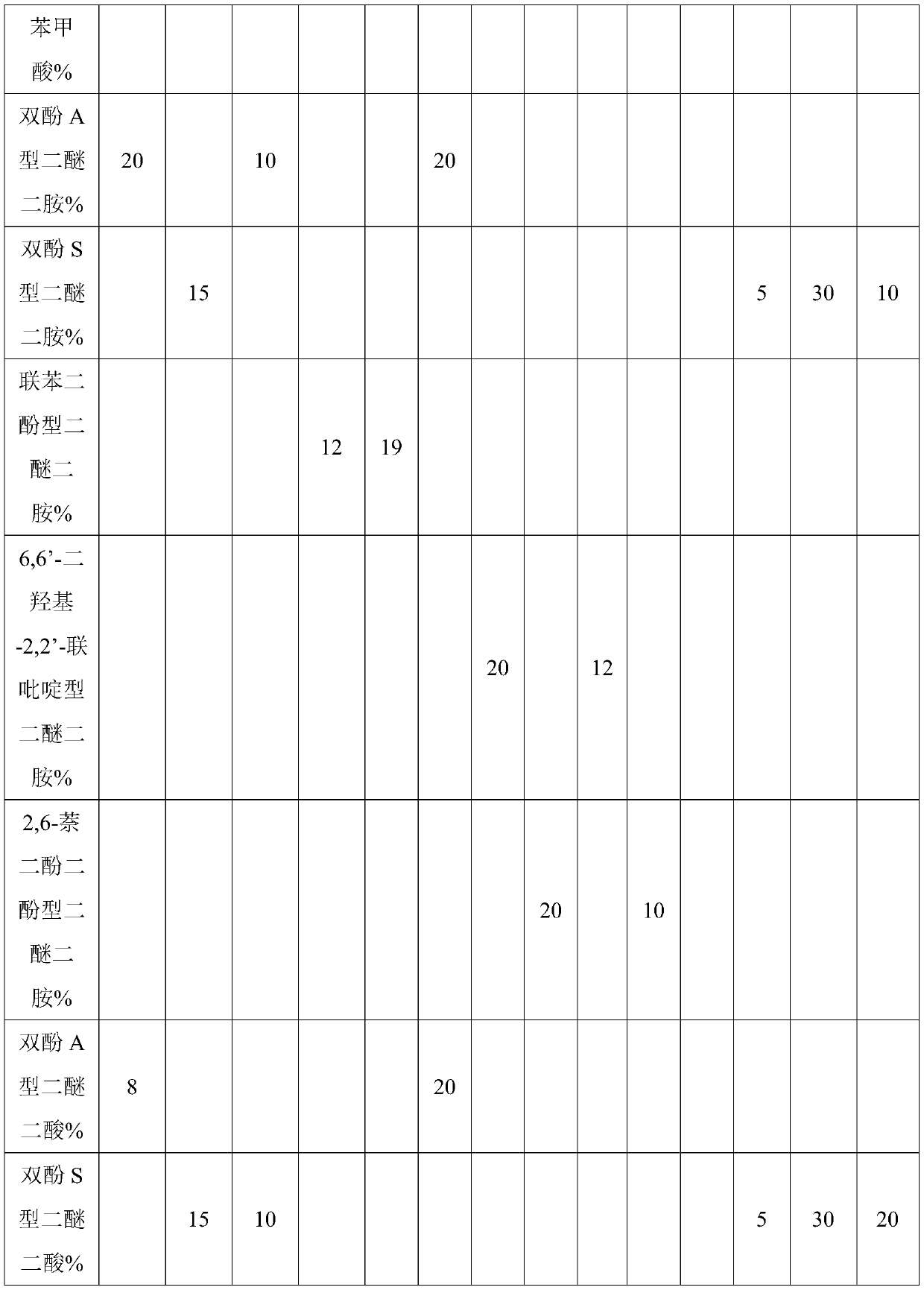

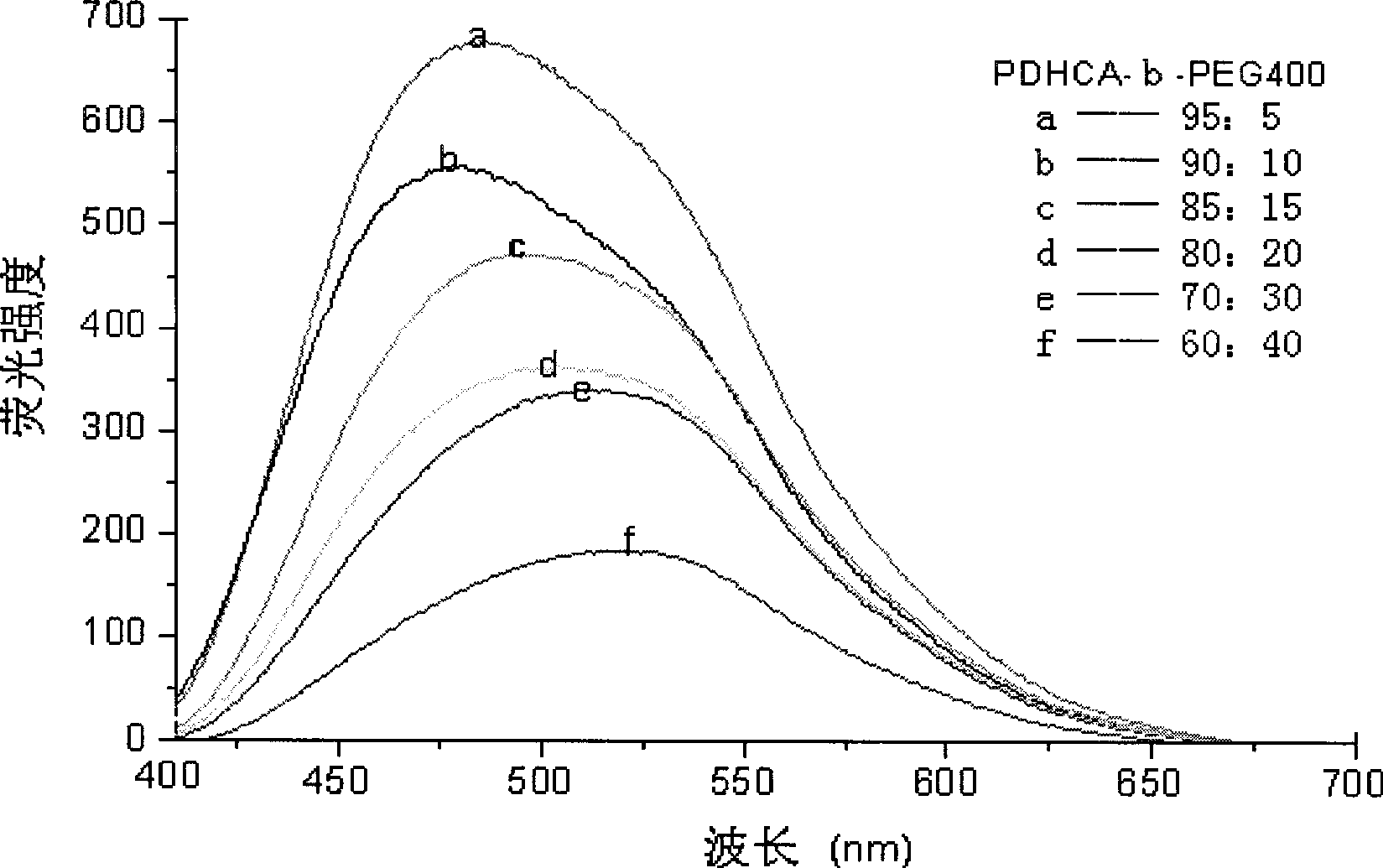

Preparation method for biodegradable fluorescent polyester multipolymer

InactiveCN101544749AMolecular weight controllableControllable glass transition temperatureSodium acetatePolyester

The invention relates to a preparation method for a biodegradable fluorescent polyester copolymer, belonging to the field of functional materials. The method comprises the following steps: using 3,4-dihydroxy cinnamic acid as a main monomer, using PEG400, PEG1000, PEG2000, PEG4000 and PEG6000 with different molecular weights, lactic acid, p-hydroxybenzoic acid or lithocholic acid as functional monomers and using sodium acetate as a catalyzer and acetic anhydride as a solvent; and adopting a two-step melting polycondensation method to obtain a caffeic acid ester copolymer with controllable molecular weight, glass transition temperature, fluorescence intensity, degradation speed, and the like so that the caffeic acid ester copolymer can be used as a degradation material or a fluorescent probe and applied to the fields of organizational projects, biological medicines, environmental protection, and the like. The invention provides a simple convenient high-efficiency method for preparing the biodegradable copolymer which has fluorescent performance.

Owner:JIANGNAN UNIV

Woundplast and preparation technology thereof

InactiveCN102166370AGood compatibilityImprove securityAbsorbent padsBandagesIsomaltooligosaccharidePeppermints

The invention discloses a woundplast and a preparation technology thereof. The woundplast consists of non-woven fabric, a hydrogel layer and a plastic film. The hydrogel layer comprises the raw materials based on weight percentage: 1%-5% of chitosan, 1%-5% of low-polymerized isomaltose, 1%-3% of peppermint oil, 1%-3% of p-hydroxybenzoic acid, 10%-30% of glycerol, 3%-8% of polyvinylpyrrolidone, 3%-8% of polyacrylic acid and 55%-75% of purified water. The prepared hydrogel layer, non-woven fabric and plastic film are coated and cut on a hydrogel coating machine set and are dried for 24h till that the moisture content is within the range from 50% to 65% so as to prepare the woundplast. The woundplast has the characteristics that the wound can be promoted to be healed, and the woundplast is flexible in use.

Owner:吴克

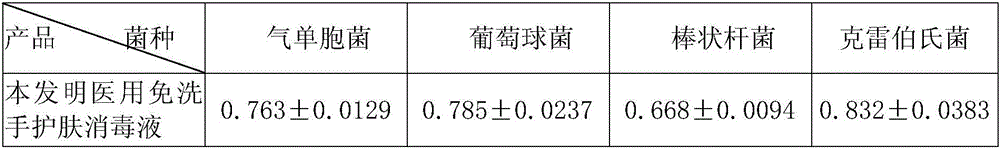

Medical hand-washing-free skin care disinfectant and preparation method thereof

ActiveCN106214573AAvoid the chance of getting sickReduce cross infectionCosmetic preparationsToilet preparationsDisinfectantNormal skin

The invention discloses a medical hand-washing-free skin care disinfectant and a preparation method thereof. The medical hand-washing-free skin care disinfectant comprises, by weight, hydrogen peroxide, tea tree oil, hyaluronic acid, mannitol, stearic acid, glycerin, triethanolamine, kathon, p-hydroxybenzoic acid, medical alcohol, traditional Chinese medicine extract and the like which serve as active components. The disinfectant can rapidly and effectively kill various bacteria and viruses on palms and among fingers, is remarkable in bacteria killing effect, convenient to use and carry, safe and efficient, and is nonpoisonous and non-irritating to the normal skin as the pH (potential of hydrogen) value of the disinfectant is approximate to that of the skin, and people can wash hands with the disinfectant without water and clean two hands at any time and in any places.

Owner:SHANDONG UNIV QILU HOSPITAL

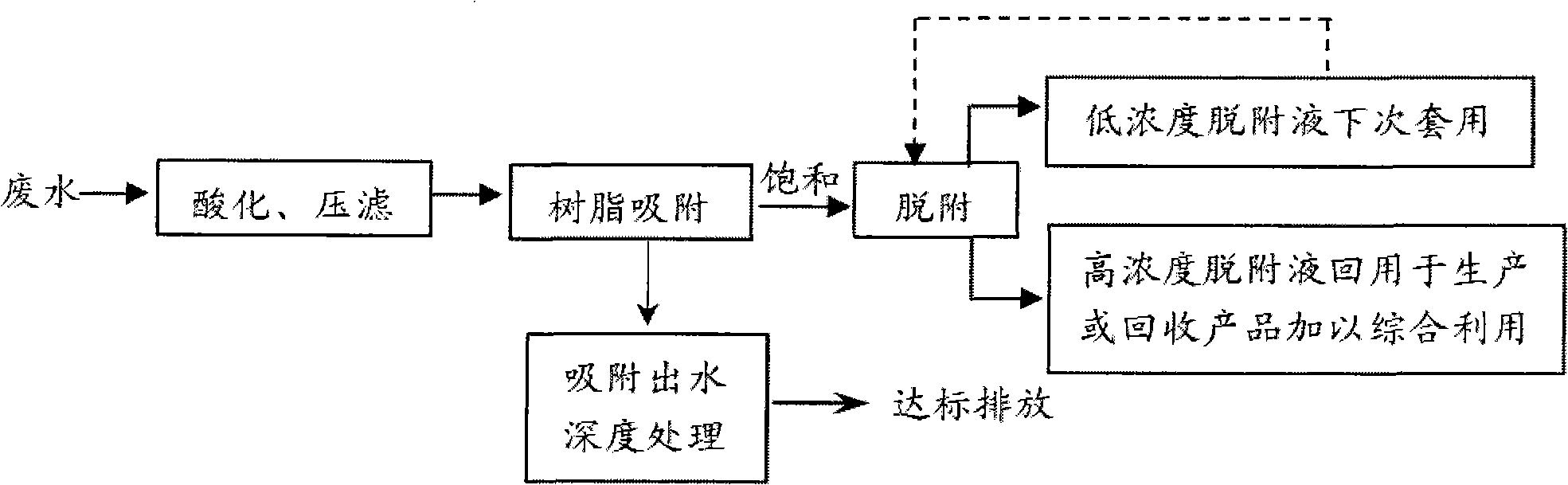

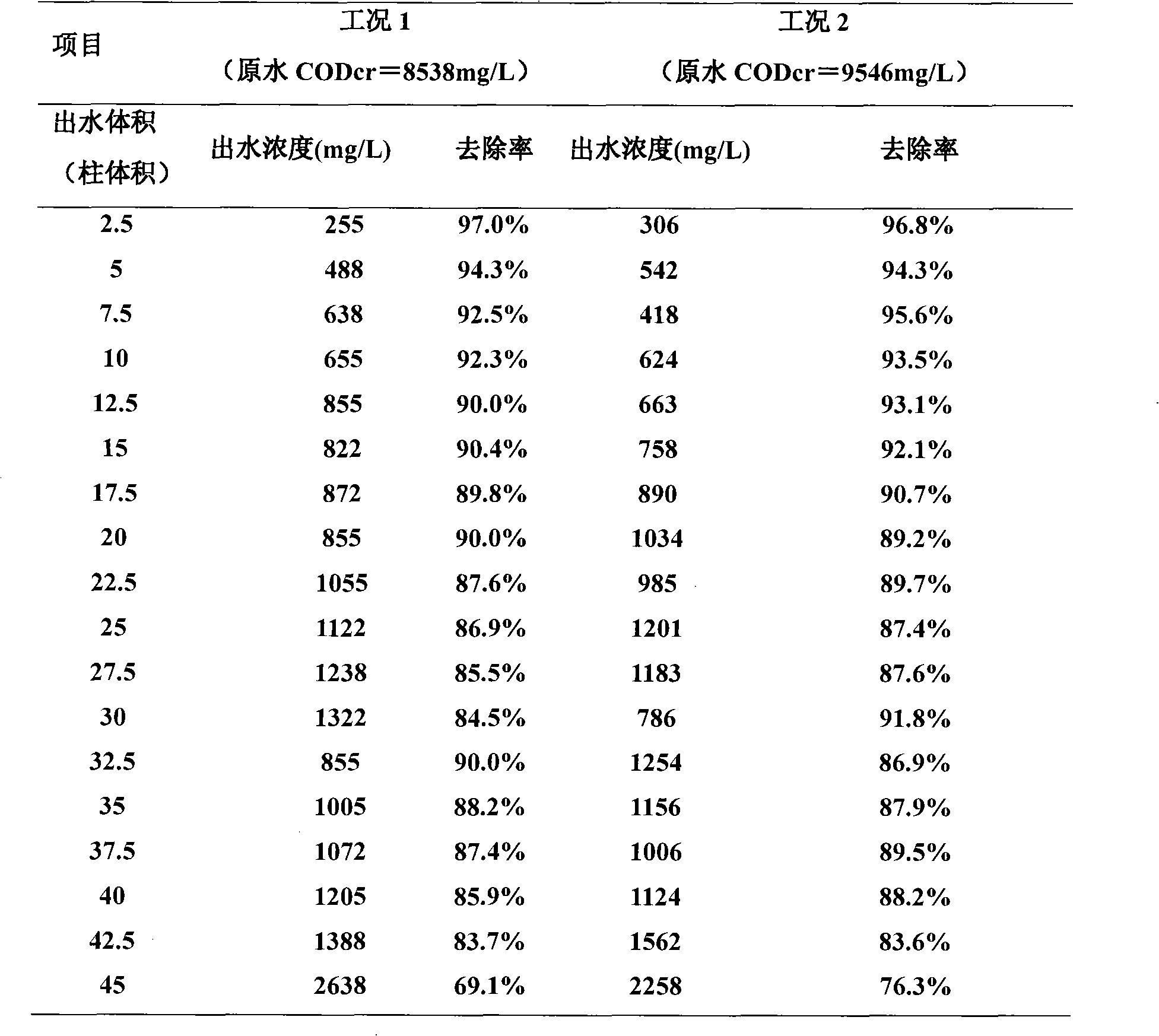

Treatment method of waste water in hydroxybenzoic acid production

InactiveCN101560044AReduce dosageImprove adsorption efficiencyWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentDesorptionWastewater

The invention discloses a treatment method of waste water in hydroxybenzoic acid production, which is characterized by comprising the following steps of: (1) conducting pretreatments of acidation, precipitation and filtering on waste water; (2) conducting adsorption treatment on the filtrate obtained in the step (1) at the temperature of 5-40 DEG C and at the flow of 0.5-2 column volume per hour through an adsorption column filled with modified macroporous absorbent resin; and (3) conducting biochemical treatment on the adsorption effluent obtained after step (2). The p-hydroxybenzoic acid recycled by the method and the intermediate thereof can be reused as raw materials in the original production technique, and waste water treatment and recycling of waste are realized simultaneously. The method has good waste water treatment effect, is easy for desorption and regeneration, reduces the use amount of the modified macroporous resin, and is easy for industrialized implementation.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

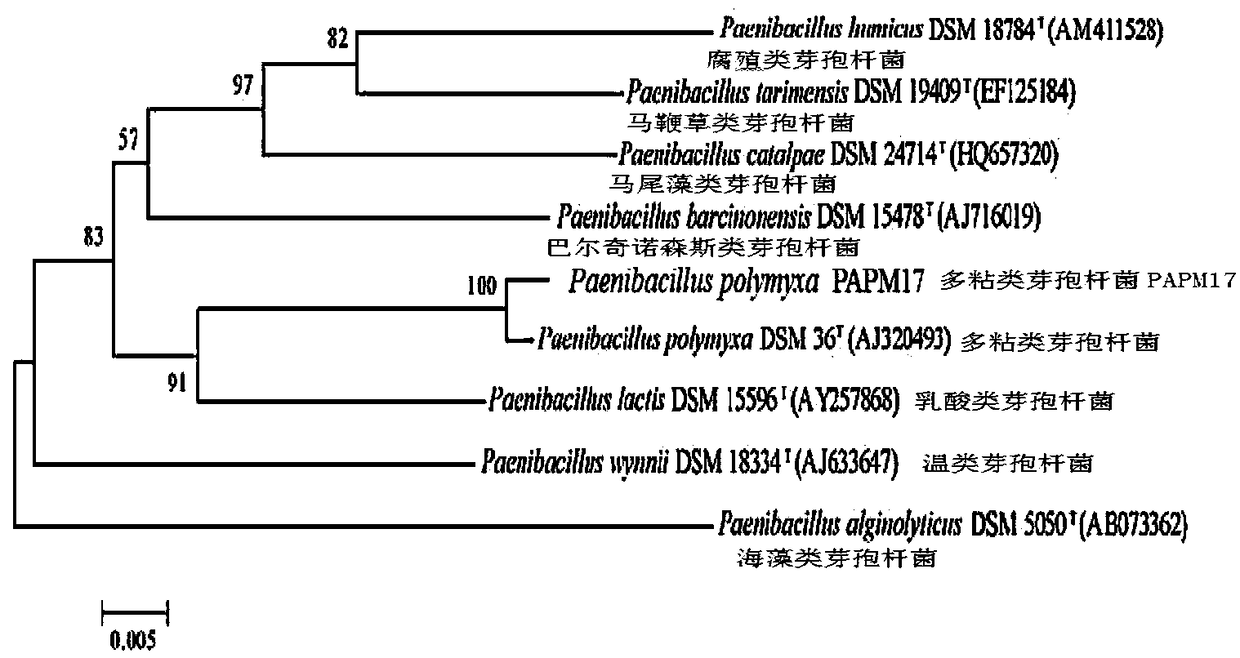

Paenibacillus polymyxa with saline-alkali resistant effect and application thereof

ActiveCN109055267APromote growthIncrease productionBiocidePlant growth regulatorsContinuous croppingGallic acid ester

The invention discloses paenibacillus polymyxa with saline-alkali resistant effect and application thereof. The paenibacillus polymyxa is paenibacillus polymyxa PAPM17 isolated from the rhizosphere soil of cotton in a saline-alkali land, and has been collected into Common Microorganism Center of China Committee for Culture Collection of Microorganisms on July 17th, 2018; the microorganism collection number is CGMCC No.16118. The paenibacillus polymyxa has the advantages that the paenibacillus polymyxa can survive in the soil of the saline-alkali land, the better degrading effect is realized onthe self-poisonous matters of plants, such as gallic acid, p-hydroxybenzoic acid and ferulic acid, the continuous cropping obstacles are reduced, and the functions of accelerating growth and increasing output are realized on the cultivated cotton in the saline-alkali land; the paenibacillus polymyxa is inoculated into a fermenting culture medium using soybean meal powder, corn pulp and molasses as the main nutrient sources to ferment, added with an additive, and spray-dried, so as to obtain the live bacterial preparation; the fermenting cycle is short, the loss of live bacteria in the spray-drying process is low, and the stability is high in the preservation process.

Owner:SHANDONG ZOETICLAND BIOLOGICAL TECH +2

Powder coating containing modified nanocarbon and preparation method of powder coating

ActiveCN103013298AImproved surface levelingImprove the decorative effectPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses a powder coating containing modified nanocarbon and a preparation method of the power coating. The powder coating consists of the following raw materials: modified epoxy resin, tetraphenol ethane tetraglycidyl ether epoxy resin, p-hydroxybenzoic acid hydroquinone diglycidyl, modified nanocarbon, crylic acid type leveling agent, film-forming resin, polydimethylsiloxane, benzoin, aluminite powder, acrylic resin, ultra-fine titanium dioxide, diethylenetriamine, resorcinol and dioctyl ester. The powder coating is a green and environmental-friendly coating, has no toxicity, has high-temperature resistance, contains no solvent and has no VOC (Volatile Organic Compounds) emission; and furthermore, the modified nanocarbon is added in the powder coating, so that the compatibility of the modified epoxy resin, the tetraphenol ethane tetraglycidyl ether epoxy resin and the p-hydroxybenzoic acid hydroquinone diglycidyl is enhanced, the surface leveling of the powder coating is improved, the powder coating has the advantage of high gloss retention and the decorative property of the powder coating is enhanced; and the qualified rate of the finished product obtained by preparing is high and the industrial mass production can be realized.

Owner:CHUZHOU HONGYUAN SPRAYING

Polishing solution and polishing method thereof

The invention discloses a polishing solution and a polishing method thereof, wherein the polishing solution comprises the following components in parts by weight: 10-20 parts of sodium doodecyl benzene sulfonate, 10-15 parts of acetic acid, 0.5-2 parts of organosilicon foam killer, 3-8 parts of sodium tripolyphosphate, 5-10 parts of polyethyleneglycol 2000, 5-10 parts of glycerol, 3-8 parts of hexamethylene tetramine, 3-6 parts of cupric sulfate, 5-10 parts of p-hydroxybenzoic acid, 15-20 parts of citric acid, 3-8 parts of ammonium chloride and 100-120 parts of solvent. A stainless steel surface polished with the polishing solution is clean and bright, has higher weatherability, and meanwhile achieves higher service efficiency and a longer service life.

Owner:WUJIANG JUNDA ELEVATOR PARTS

Preparation method of high-performance thermotropic liquid crystal polyarylester

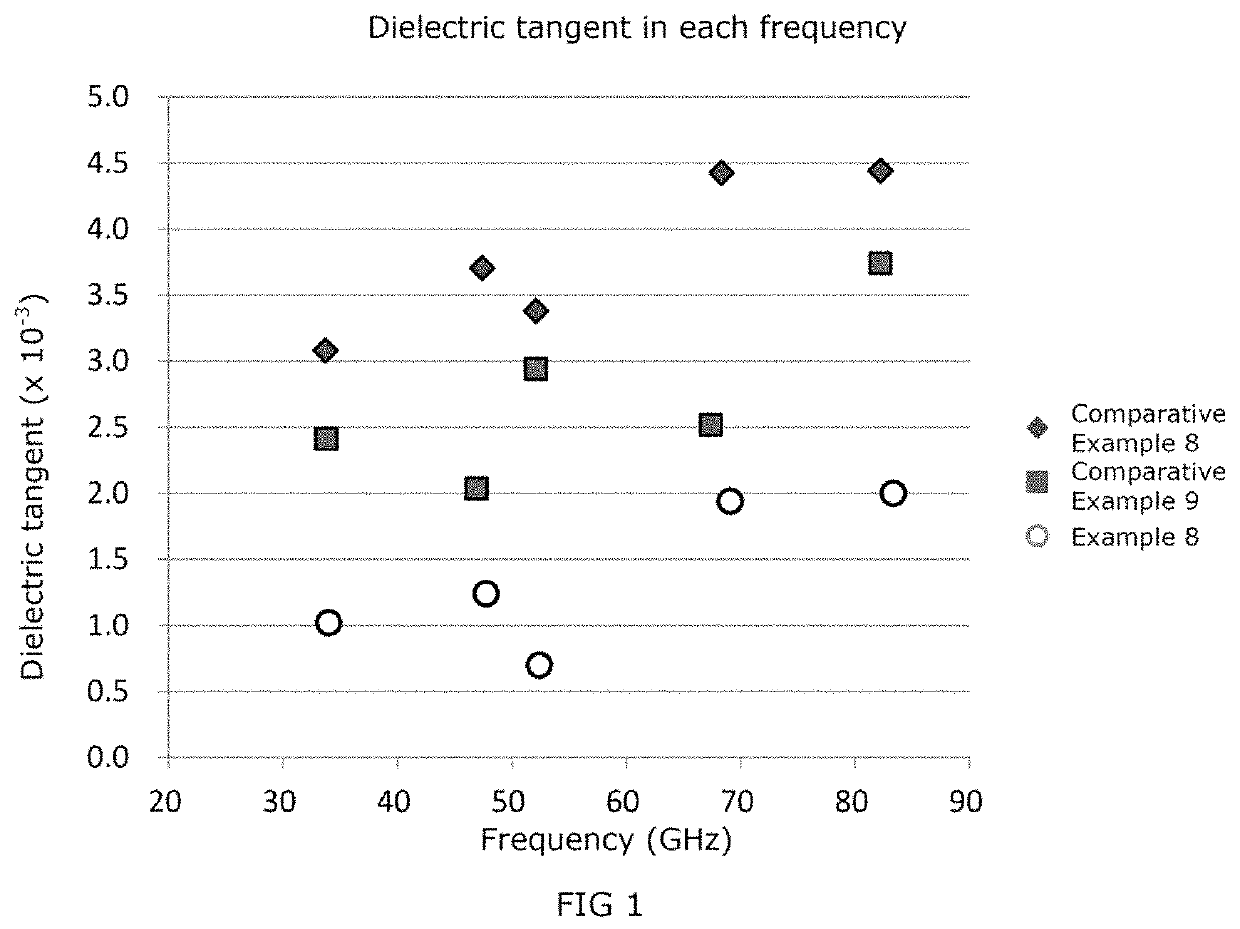

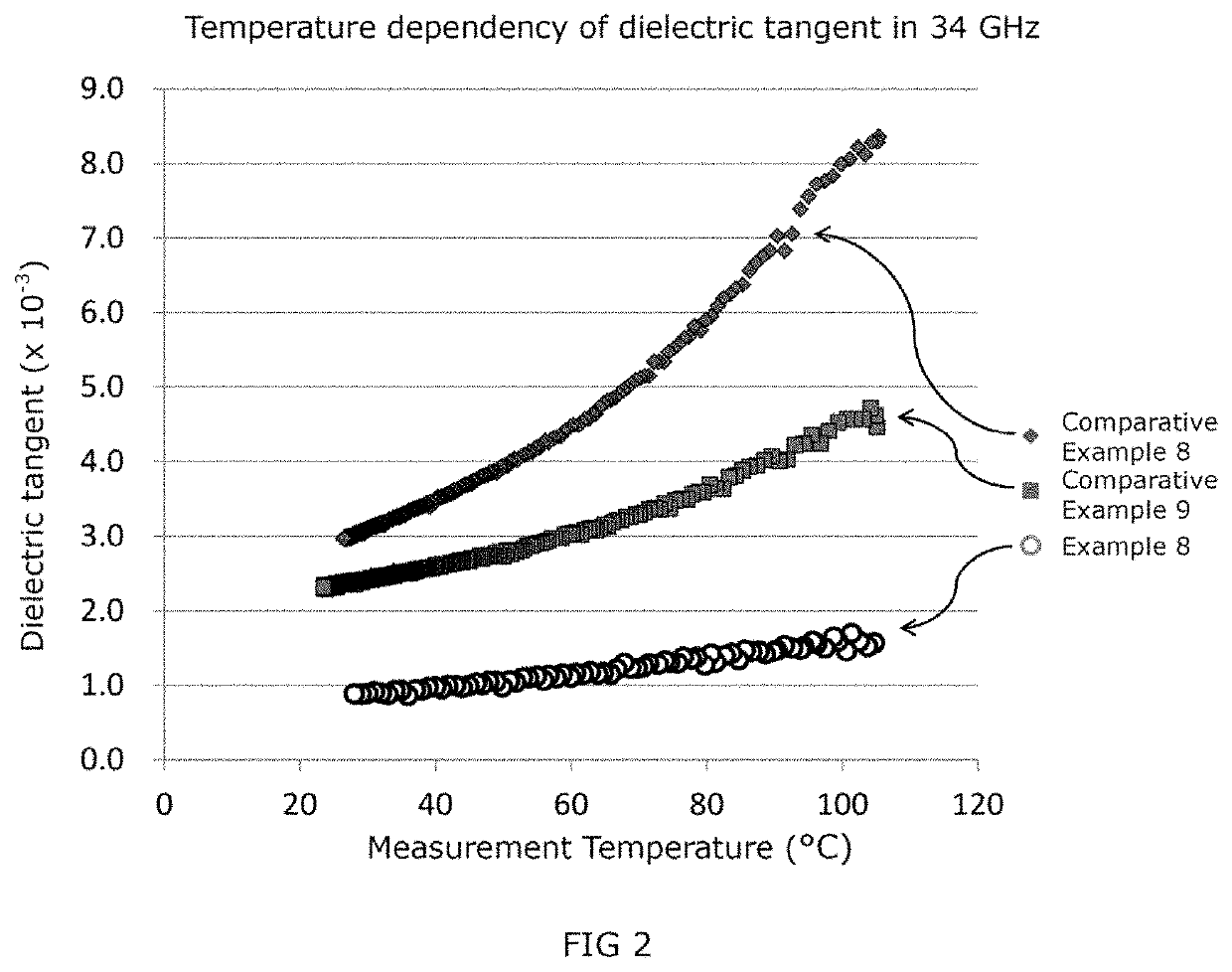

InactiveCN112126205ALow dielectric constantReduce dielectric lossLiquid crystal compositionsBenzoic acidPolymer science

The invention discloses a preparation method of high-performance thermotropic liquid crystal polyarylester, and relates to a preparation method of thermotropic liquid crystal polyarylester with low dielectric constant and high impact strength, which comprises the following steps of: 1, reacting 2, 5-dihydroxy terephthalic acid with p-hydroxybenzoic acid, 2-hydroxy 6-naphthoic acid, p-hydroxybenzoic acid, p-hydroxybenzoic acid and p-hydroxybenzoic acid; adding acetic anhydride, 4-aminopyridine and an antioxidant into a polymerization kettle, and carrying out melt polycondensation to prepare a prepolymer of the thermotropic liquid crystal polyarylester; 2, performing solid-phase polycondensation reaction on the prepolymer in a rotary kiln under the protection of nitrogen to obtain high-molecular-weight polymer powder; 3, mixing the high-molecular-weight polymer powder with polytetrafluoroethylene resin, cooling and drawing to prepare primary polyarylester; and 4, carrying out heat treatment on the primary polyarylester. The dielectric constant of the thermotropic liquid crystal polyarylester is less than 3.0, the dielectric loss is less than 0.003, the impact strength can reach 35-50kJ / m < 2 >, and the thermotropic liquid crystal polyarylester has high dimensional safety and excellent mechanical properties and processability.

Owner:宁波聚嘉新材料科技有限公司 +1

Wholly aromatic liquid crystalline polyester resin, molded article, and electric and electronic components

ActiveUS20200040133A1Low dielectric tangentProlonged heat treatmentCoatingsLiquid crystallineBenzoic acid

[Problem] To provide a wholly aromatic liquid crystalline polyester resin having an excellent heat resistance and processability while having an extremely low dielectric tangent[Solving means] A wholly aromatic liquid crystalline polyester resin according to the present invention comprises,structural unit (I) derived from p-hydroxybenzoic acid,structural unit (II) derived from 6-hydroxy-2-naphthoic acid,structural unit (III) derived from an aromatic diol compound,structural unit (IV) derived from an aromatic dicarboxylic acid, whereinthe composition ratio (mol %) of said structural units (I) to (IV) satisfies the following conditions:2 mol %≤structural unit (I)≤9 mol %40 mol %≤structural unit (II)≤75 mol %9 mol %≤structural unit (III)≤24 mol %9 mol %≤structural unit (IV) 24 mol %.

Owner:ENEOS CORP

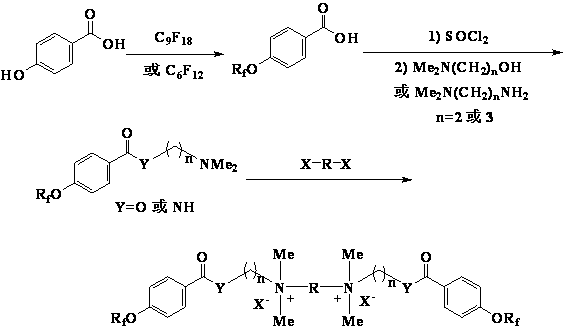

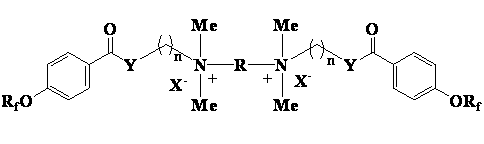

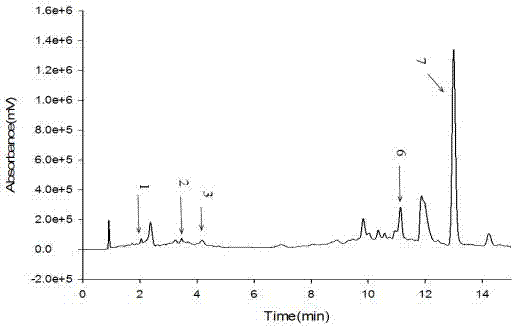

Cationic type gemini fluorinated surfactant based on perfluorinated nonene and perfluorinated hexene and preparation method of cationic type gemini fluorinated surfactant

ActiveCN102908937AHigh reactivityReactive and expensiveOrganic compound preparationTransportation and packagingBenzoic acidPolymer science

The invention discloses a cationic type gemini fluorinated surfactant based on perfluorinated nonene and perfluorinated hexene and a preparation method of the cationic type gemini fluorinated surfactant. The preparation method comprises the following steps of: with the perfluorinated nonene or perfluorinated hexene as a raw material, condensing the perfluorinated nonene or perfluorinated hexene with p-hydroxybenzoic acid, and carrying out chlorination on a matter obtained after condensation and thionyl chloride to prepare perfluorinated alkene oxyl benzoyl chloride; condensing the perfluorinated alkene oxyl benzoyl chloride without separation with 2-dimethylamino ethanol, 3-dimethylamino propanol, 2-dimethylamino ethylamine and 3-dimethylamino propylamine to obtain perfluorinated alkene oxyl benzoate or perfluorinated alkene oxyl benzamide with tertiary amine at an alkanol part or amine part; and finally, condensing the perfluorinated alkene oxyl benzoate or perfluorinated alkene oxyl benzamide with 1,2-dihaloethane, 1,3-dihalopropane, 1,4-dichlorobutane, 1,5-dichloropentane or 3-oxa-1,5-dichloropentane to prepare a quaternary ammonium gemini fluorinated surfactant. The synthesized compound is high in surface activity and is low in critical micelle concentration, has the characteristics of simpleness in synthesization, low cost and the like and has good application prospect.

Owner:江苏超至和新材料有限公司

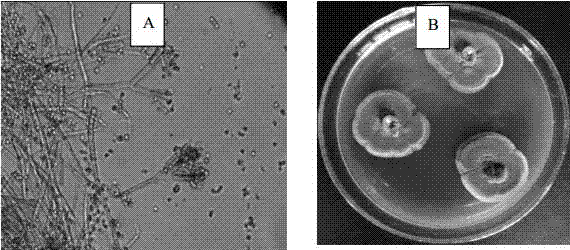

Fungus with strong weed suppression effect screened from passion fruit rhizosphere soil

InactiveCN107164234AHas an anti-herb effectEnvironmentally safeBiocideFungiSalicylic acidAspergillus sydowii

The invention belongs to the field of microbial herbicides and particularly relates to weed suppression fungus screened from passion fruit rhizosphere soil. Lettuce (compositae), barnyard grass (gramineae) and lysimachia barystachys (gramineae) are taken as receptors separately, biological test is carried out on the weed suppression ability of a fungus strain fermentation liquid, and the condition that the weed suppression fungus has a very high inhibition rate on root length and plant height of two receptors is found out. The condition that protocatechuic acid, p-hydroxybenzoic acid, vanillic acid, salicylic acid and cinnamic acid contain phenolic acid with a weed suppression effect is detected in the fermentation liquid. The strain is named FJ-01-BXG-08. The analysis and identification results on the morphology and ITS sequence of the strain show that the strain is one of Aspergillus sydowii (aspergillus sydowii), and strong weed suppression fungus aspergillus sydowii (Aspergillus sydowii) is screened from eucalyptus soil for the first time.

Owner:FUJIAN AGRI & FORESTRY UNIV

Synthesis method and application of long-chain methyl p-hydroxybenzoate

ActiveCN104119230AIncrease production capacityGood effectOrganic compound preparationCarboxylic acid esters preparationSynthesis methodsTridecyl alcohol

The invention provides a synthesis method of long-chain methyl p-hydroxybenzoate, which comprises the following steps: 1) adding p-hydroxybenzoic acid, alcohol and a catalyst into an esterification reactor, adding a water-carrying agent, and heating under reflux for dehydration; 2) cooling the reaction solution, adding n-hexane while stirring, cooling to -20-25 DEG C, standing for 0.5-10 hours, filtering to obtain a filter cake and a filtrate, and drying the filter cake to obtain white powdery long-chain methyl p-hydroxybenzoate; and 3) carrying out vacuum evaporation to remove the n-hexane in the filtrate to obtain a surplus reaction solution, adding the p-hydroxybenzoic acid, alcohol and water-carrying agent into the surplus reaction solution, and repeating the steps above, wherein the alcohol is normal decyl alcohol, normal undecyl alcohol, normal lauryl alcohol or normal tridecyl alcohol, and the water-carrying agent is benzene, cyclohexane or n-hexane. The n-hexane is directly added to precipitate the long-chain methyl p-hydroxybenzoate from the reaction solution without evaporating out excessive alcohol. The method has the advantages of separable product, reusable catalyst, alcohol, n-hexane and water-carrying agent, and no environment pollution.

Owner:李炳洁

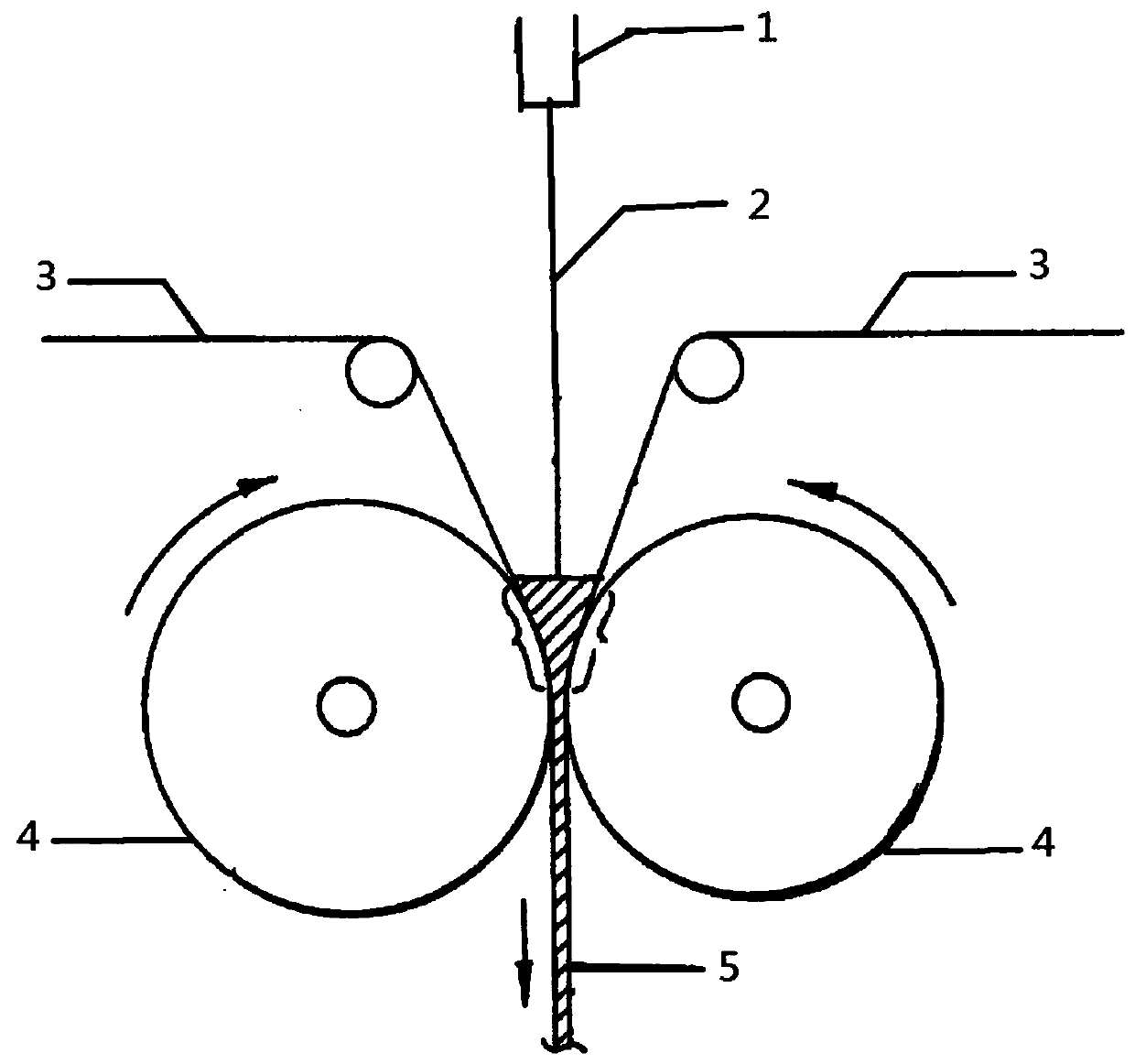

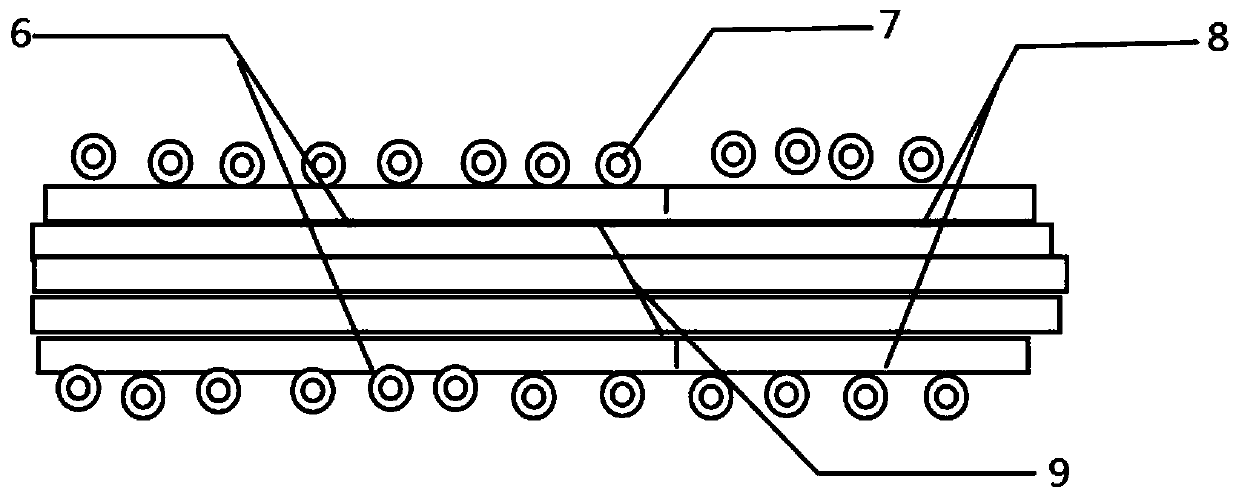

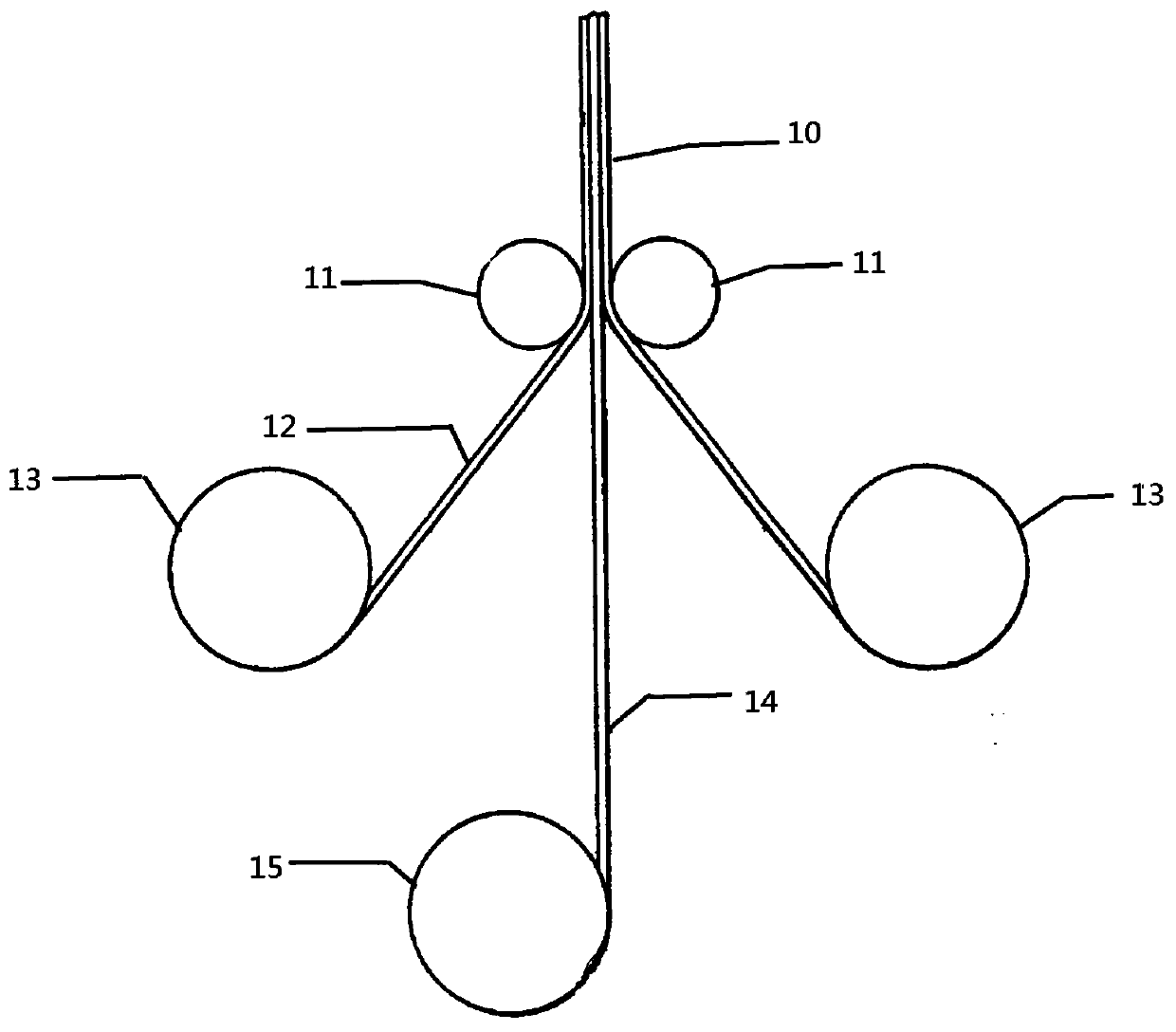

Industrial production process of liquid crystal polyester film

The invention discloses an industrial production process of a liquid crystal polyester film. The process uses p-hydroxybenzoic acid, hydroquinone, terephthalic acid, terephthaloyl chloride, 2-hydroxy-6-naphthoic acid, acetic anhydride and trifluoromethanesulfonic acid as raw materials to synthesize a prepolymer for a liquid crystal polyester copolymer, the prepolymer is extruded to form prepolymersheets, the prepolymer sheets are subjected to crushing, dicing and drying process, after internal mixing, a melt is extruded into a sandwich structure containing polyimide film-liquid crystal polyester melt-polyimide film through a T-shaped mold, and then the sandwich structure is cooled to form a primary liquid crystal polyester film containing a liquid crystal polyester copolymer; after bidirectional stretching, the primary liquid crystal polyester film is cooled and shaped to form a sandwich structure containing the liquid crystal polyester copolymer film, then the polyimide film on the surface is separated and removed from the surface of the liquid crystal polyester film, and the stripped liquid crystal polyester film is coiled to form a liquid crystal polyester film. The liquid crystal polyester film produced by adopting the technology is widely applied to the fields of electronics, electric appliances, automobiles, machinery, aviation, aerospace, chemical industry and the like.

Owner:陈祚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com