High-strength gypsum board and preparation method thereof

A gypsum board and high-strength technology, applied in the field of high-strength gypsum board and its preparation, can solve the problems of low mechanical strength and the like, and achieve the effects of simple preparation, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

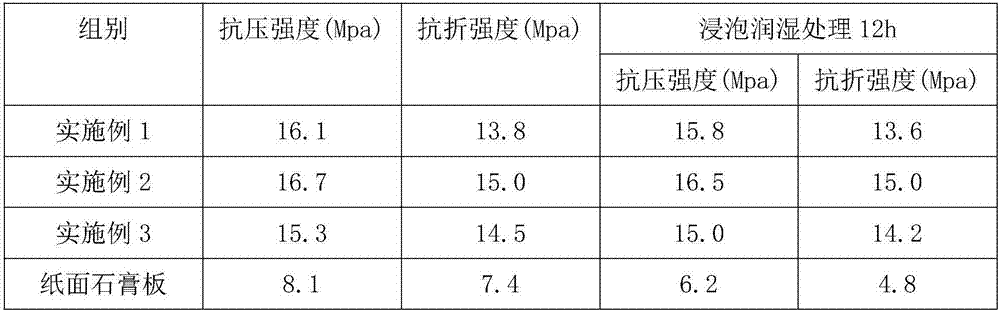

Examples

Embodiment 1

[0023] A high-strength gypsum board, prepare the following raw materials to be prepared: 80kg of modified gypsum powder, 20kg of zuoyun clay, 15kg of anorthite powder, 10kg of nano tourmaline powder, 20kg of heavy calcium carbonate powder, 10kg of borax, 10kg of silicon carbide fiber, 4kg of isopropyl paraben, 3kg of silicone emulsion, 1kg of coupling agent, 1kg of antifungal agent, 1kg of defoaming agent and 1kg of adhesive;

[0024] The above-mentioned modified gypsum powder is prepared by the following steps: Weigh 80kg of desulfurized gypsum and pre-dry it at 80°C, then transport it to a calciner, calcinate it at a temperature of 140°C for 1 hour, and cool the output to 50°C , add sorbitan monooleate equivalent to 3% by weight of desulfurized gypsum and liquid paraffin equivalent to 4% by weight of desulfurized gypsum, stir and mix evenly, and then transport it to an impact mill to grind to a particle size of 400 μm, cool and age Promptly make the modified gypsum powder re...

Embodiment 2

[0032] A high-strength gypsum board, prepare the following raw materials to be prepared: 100kg of modified gypsum powder, 30kg of zuoyun clay, 20kg of anorthite powder, 15kg of nano tourmaline powder, 25kg of heavy calcium carbonate powder, 15kg of borax, 15kg of silicon carbide fiber, 6kg of isopropyl paraben, 5kg of silicone emulsion, 3kg of coupling agent, 3kg of antifungal agent, 2kg of defoaming agent and 2kg of adhesive;

[0033] The above-mentioned modified gypsum powder is prepared by the following steps: Weigh 100kg of desulfurized gypsum and pre-dry it at 85°C, then transport it to a calciner, calcinate it at 160°C for 1.5h, and cool the output to 60°C ℃, add sorbitan monooleate equivalent to 4% of the weight of desulfurized gypsum and liquid paraffin equivalent to 6% of the weight of desulfurized gypsum, stir and mix evenly, and then transport it to an impact mill and grind it to a particle size of 300 μm. After cooling Aging is to obtain the modified gypsum powder ...

Embodiment 3

[0041] A high-strength gypsum board, prepare the following raw materials to be prepared: 120kg of modified gypsum powder, 40kg of zuoyun clay, 25kg of anorthite powder, 20kg of nano tourmaline powder, 30kg of heavy calcium carbonate powder, 20kg of borax, 20kg of silicon carbide fiber, 8kg of isopropyl paraben, 7kg of silicone emulsion, 5kg of coupling agent, 5kg of antifungal agent, 3kg of defoaming agent and 3kg of adhesive;

[0042]The above-mentioned modified gypsum powder is prepared by the following steps: Weigh 120kg of desulfurized gypsum and pre-dry it at 90°C, then transport it to a calciner, calcinate it at 180°C for 2 hours, and cool the output to 70°C , add sorbitan monooleate equivalent to 5% of the weight of desulfurized gypsum and liquid paraffin equivalent to 8% of the weight of desulfurized gypsum, stir and mix evenly, and then transport it to an impact mill and grind it to a particle size of 200 μm. After cooling, age Promptly make the modified gypsum powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com