Novel thermotropic liquid crystal polymer and preparation method thereof

A thermotropic liquid crystal and polymer technology, applied in the polymer field, can solve the problems of limitation, poor mechanical properties, difficult processing, etc., and achieve the effect of reducing cost and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

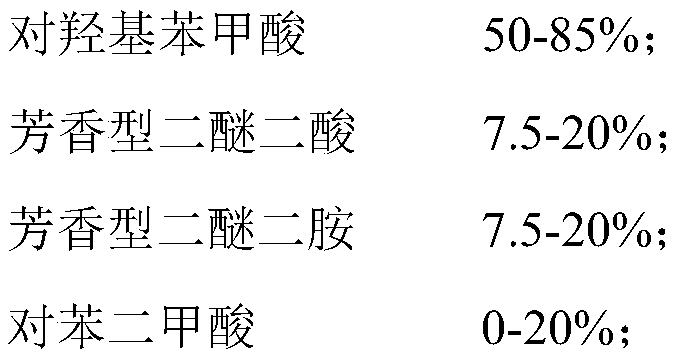

Method used

Image

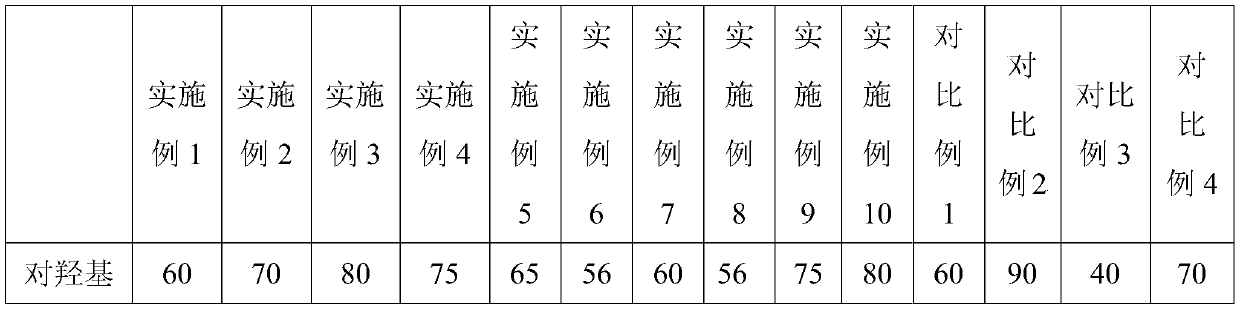

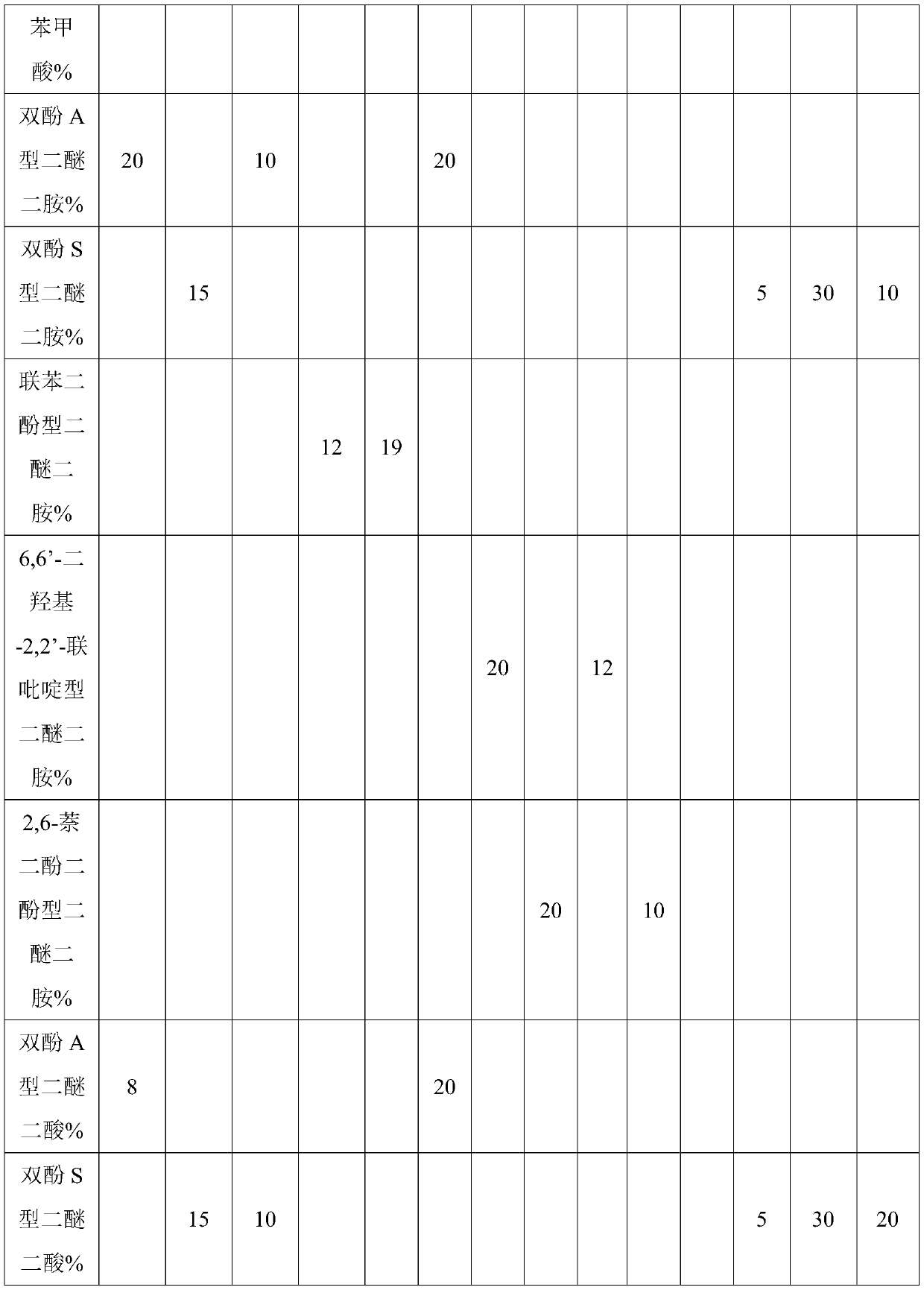

Examples

Embodiment 1

[0089] S1: Add 301.1g acetic anhydride solution, 202.4g p-hydroxybenzoic acid, 201.97g bisphenol A diether diamine, 91.82 g of bisphenol A diether diacids, 49.01 g of terephthalic acid, and then 0.07 g of N-methylimidazole were added to the stirred mixture. After the inside of the reactor was sufficiently replaced with nitrogen, the temperature of the mixture was raised to 150° C. within 20 minutes under a nitrogen flow, and while maintaining the temperature, the mixture was refluxed for 1 hour. In 2 hours and 20 minutes, the temperature was raised to 315°C, while the distillate of by-product acetic acid and unreacted acetic anhydride was removed, and the time point when the torque was raised was considered as the end of the reaction, and the prepolymer was taken out and cooled to After room temperature, use a universal crusher to crush the prepolymer into powder, and dry the crushed material in vacuum at 130°C for 2 hours to obtain the prepolymer powder;

[0090] S2: Add pre...

Embodiment 2

[0092]S1: Add 272.27g acetic anhydride solution, 202.4g p-hydroxybenzoic acid, 136.67g bisphenol S type diether diamine, 154.99 g of bisphenol S type diether diacid, and then, 0.11 g of N-methylimidazole was added to the stirred mixture. After the inside of the reactor was sufficiently replaced with nitrogen, the temperature of the mixture was raised to 155° C. within 25 minutes under a nitrogen flow, and while maintaining the temperature, the mixture was refluxed for 1.5 hours. In 2 hours and 40 minutes, the temperature was raised to 320 ° C, while removing the distillate of by-product acetic acid and unreacted acetic anhydride, the time point when the torque was raised was considered to be the end of the reaction, and the prepolymer was taken out and cooled to After room temperature, use a universal crusher to crush the prepolymer into powder, and dry the crushed material in vacuum at 130°C for 2 hours to obtain the prepolymer powder;

[0093] S2: Put the prepolymer powder ...

Embodiment 3

[0095] S1: Add 283.59g acetic anhydride solution, 202.4g p-hydroxybenzoic acid, 75.74g bisphenol A type diether diamine, 90.49 g of bisphenol S type diether diacid, and then, 0.07 g of N-methylimidazole was added to the stirred mixture. After the inside of the reactor was sufficiently replaced with nitrogen, the temperature of the mixture was raised to 150° C. within 30 minutes under a nitrogen flow, and while maintaining the temperature, the mixture was refluxed for 1 hour. Raise the temperature to 315°C within 3 hours while removing the distillate of by-product acetic acid and unreacted acetic anhydride. It is considered that the time point when the torque increases is the end of the reaction, and the prepolymer is taken out. After cooling to room temperature , use a universal crusher to crush the prepolymer into powder, and dry the crushed material in vacuum at 130°C for 2 hours to obtain the prepolymer powder;

[0096] S2: Add prepolymer powder into the reaction kettle, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com