Method for reclaiming and treating phenol and p-hydroxybenzoic acid in p-hydroxybenzoic acid technique waste water

A recovery and treatment technology for p-hydroxybenzoic acid, applied in chemical instruments and methods, chemical recovery, separation/purification of carboxylic acid compounds, etc., can solve problems such as no discovery in extraction and recovery research, and reduce recovery and treatment costs and operating costs Low and save the effect of raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

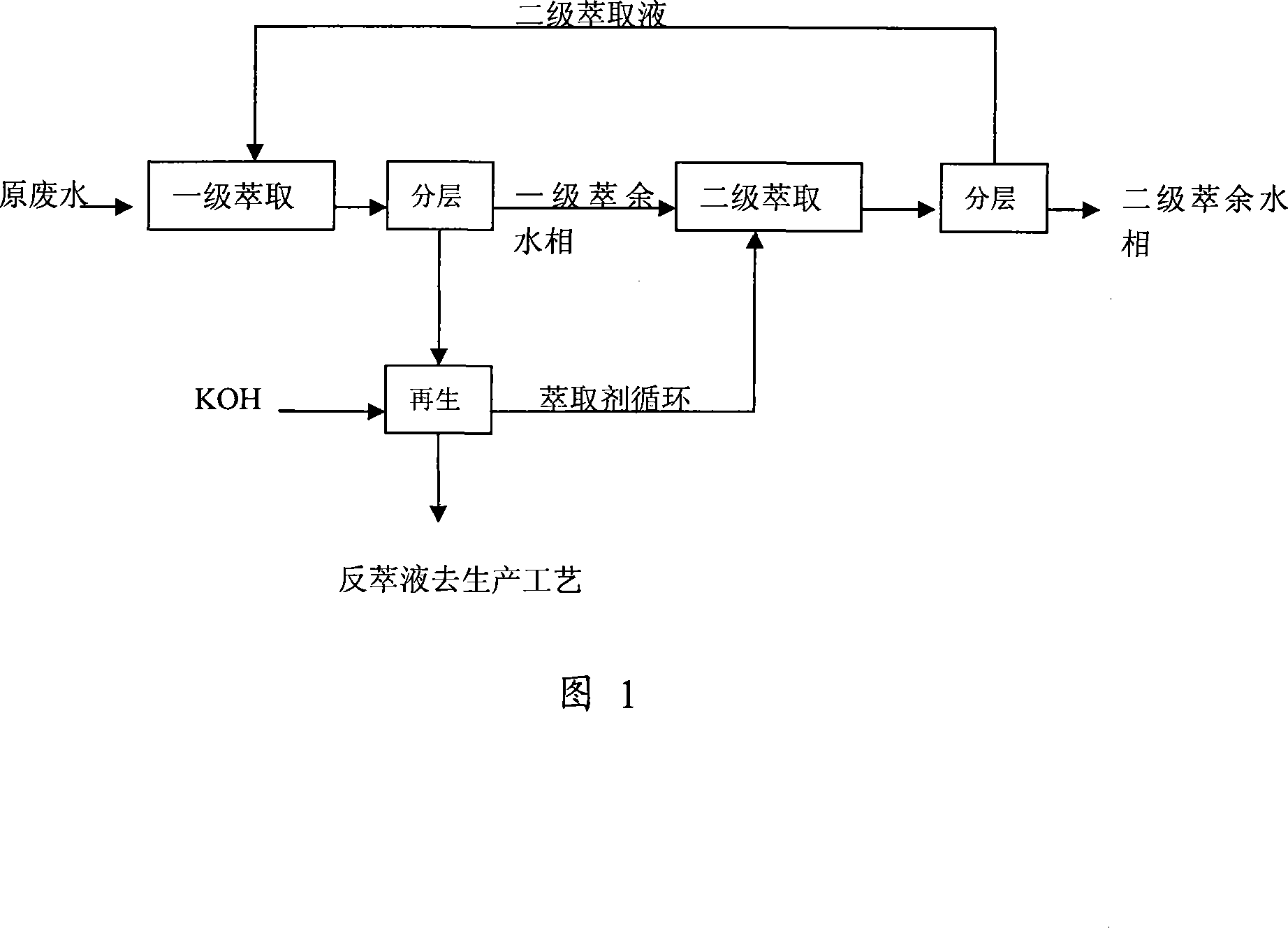

[0065] Embodiment 1, with reference to Fig. 1: extract p-hydroxybenzoic acid process waste water with extractant, phenol and p-hydroxybenzoic acid wherein are reclaimed simultaneously; Extractant adopts trioctylamine diluted with xylene, trioctylamine and The volume ratio of xylene is 1:2.3. The oil-water ratio during extraction was 0.3.

[0066] After back-extracting the primary extract with potassium hydroxide solution, the obtained regenerated extractant is subjected to secondary extraction of the primary raffinate aqueous phase. The concentration of the potassium hydroxide solution is 15%; the volume ratio of the extract and the potassium hydroxide solution is 1.5:1.

[0067] The stripping solution is returned to the raw material of the production process for carboxylation reaction.

[0068] The pH at the time of extraction was 1.26. The mixing time during extraction is 1 min to 5 min.

Embodiment 2

[0069] Embodiment 2 is basically the same as Embodiment 1, but has the following changes:

[0070] The extractant adopts trioctylamine, and the oil-water ratio during extraction is 0.5;

[0071] The concentration of potassium hydroxide solution is 20%;

[0072] The volume ratio of extract and potassium hydroxide solution is 3:1.

Embodiment 3

[0073] Embodiment 3 is basically the same as Embodiment 1, but has the following changes:

[0074] The extractant is tributyl phosphate; the oil-water ratio during extraction is 0.3;

[0075] The concentration of potassium hydroxide solution is 10%;

[0076] The volume ratio of extract and potassium hydroxide solution is 1.8:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com