Preparation method and application of novel weather-resistant composite waterproof material

A waterproof material and weather-resistant technology, which is applied in the field of preparation of new weather-resistant composite waterproof materials, can solve the problems of general effect, reduced mechanical properties and weather resistance of materials, and single effect of compounds, so as to improve mechanical properties, tensile strength and Effects of improved elongation at break, increased mechanical properties and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] A. Preparation of SBS-g-COOH.

[0038] Weigh 10g of SBS and 30g of solvent, add SBS to the solvent and mix and stir, add 0.075g of initiator after the SBS dissolves, then add 5g of graft compound through a constant pressure dropping funnel, and ice-bath for 10min. 2 Under protection, the flask was placed in a water bath at 60 °C for 12 h; after the reaction was completed, the flask was placed in an ice bath to terminate the reaction, and a transparent viscous SBS-g-COOH solution was obtained.

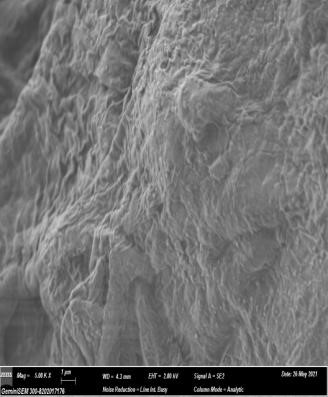

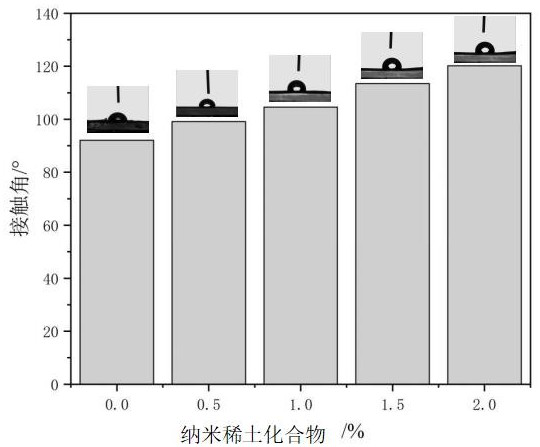

[0039] B. Preparation of SBS-g-COOH / nano rare earth compound.

[0040] Weigh 20g of SBS-g-COOH solution and 0.1g of nano-rare earth compound, add the nano-rare earth compound into the SBS-g-COOH solution, stir evenly, heat and react in a water bath at 70°C for 2 hours, and obtain SBS-g-COOH / nanometer rare earth compound after the reaction compound solution, the solution was poured into a petri dish, and dried in an oven at 50°C for 24 hours.

example 2

[0042] A. Preparation of SBS-g-COOH.

[0043] Weigh 10g of SBS and 30g of solvent, add SBS to the solvent and mix and stir, add 0.075g of initiator after the SBS dissolves, then add 5g of graft compound through a constant pressure dropping funnel, and ice-bath for 10min. 2 Under protection, the flask was placed in a water bath at 60 °C for 12 h; after the reaction was completed, the flask was placed in an ice bath to terminate the reaction, and a transparent viscous SBS-g-COOH solution was obtained.

[0044] B. Preparation of SBS-g-COOH / nano rare earth compound.

[0045]Weigh 20g of SBS-g-COOH solution and 0.2g of nano-rare earth compound, add the nano-rare earth compound into the SBS-g-COOH solution, stir evenly, heat and react in a water bath at 70°C for 2 hours, and obtain SBS-g-COOH / nanometer rare earth compound after the reaction compound solution, the solution was poured into a petri dish, and dried in an oven at 50°C for 24 hours.

example 3

[0047] A. Preparation of SBS-g-COOH.

[0048] Weigh 10g of SBS and 30g of solvent, add SBS to the solvent and mix and stir, add 0.15g of initiator after the SBS is dissolved, then add 5g of graft compound through a constant pressure dropping funnel, and ice-bath for 10min. 2 Under protection, the flask was placed in a water bath at 60 °C for 12 h; after the reaction was completed, the flask was placed in an ice bath to terminate the reaction, and a transparent viscous SBS-g-COOH solution was obtained.

[0049] B. Preparation of SBS-g-COOH / nano rare earth compound.

[0050] Weigh 20g of SBS-g-COOH solution and 0.3g of nano-rare earth compound, add the nano-rare earth compound into the SBS-g-COOH solution, stir evenly, heat the reaction in a water bath at 70°C for 2 hours, and obtain SBS-g-COOH / nanometer rare earth compound after the reaction compound solution, the solution was poured into a petri dish, and dried in an oven at 50°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com