Flame-retardant waterborne polyurethane adhesive and preparation method thereof

A technology of water-based polyurethane and flame-retardant adhesive, applied in polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve problems affecting biological growth and human health, aromatic hydrocarbon solvents are highly toxic, and pollute the atmosphere. Application prospects and economic benefits, excellent mechanical properties, and the effect of increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

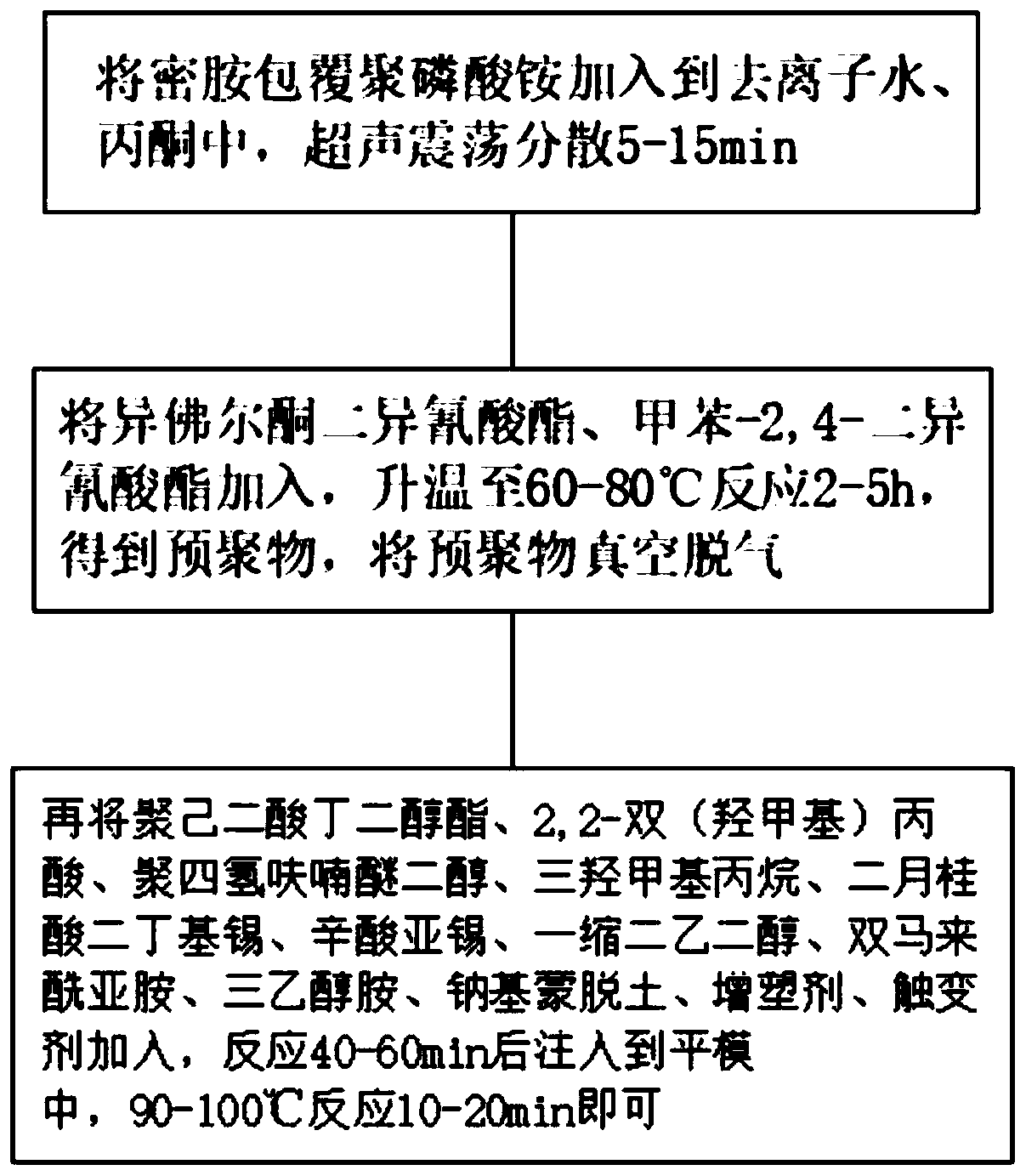

Method used

Image

Examples

Embodiment 1

[0028] A water-based polyurethane flame-retardant adhesive prepared from the following raw materials in weight fraction:

[0029] 32 parts of isophorone diisocyanate, 13 parts of toluene-2,4-diisocyanate, 8 parts of polybutylene adipate, 25 parts of 2,2-bis(hydroxymethyl)propionic acid, polytetrahydrofuran ether two 14 parts of alcohol, 1 part of trimethylolpropane, 0.3 part of dibutyltin dilaurate, 0.1 part of stannous octoate, 6 parts of diethylene glycol, 4 parts of bismaleimide, 10 parts of acetone, triethanolamine 2 parts, 7 parts of sodium-based montmorillonite, 18 parts of melamine-coated ammonium polyphosphate, 3 parts of plasticizer di-n-octyl phthalate, organic bentonite and polyamide wax in a mass ratio of 1:1 2 parts of thixotropic agent and 12 parts of deionized water.

[0030] The preparation method of melamine-coated ammonium polyphosphate is as follows:

[0031] Add melamine resin to deionized water, heat up to 45°C and stir to dissolve, then add phosphoric acid wit...

Embodiment 2

[0037] A water-based polyurethane flame-retardant adhesive prepared from the following raw materials in weight fraction:

[0038] 40 parts of isophorone diisocyanate, 16 parts of toluene-2,4-diisocyanate, 5 parts of polybutylene adipate, 22 parts of 2,2-bis(hydroxymethyl)propionic acid, polytetrahydrofuran ether two 16 parts of alcohol, 1.5 parts of trimethylolpropane, 0.4 parts of dibutyltin dilaurate, 0.1 part of stannous octoate, 5 parts of diethylene glycol, 3 parts of bismaleimide, 13 parts of acetone, triethanolamine 1 part, 8 parts of sodium-based montmorillonite, 18 parts of melamine-coated ammonium polyphosphate, 3 parts of plasticizer dicyclohexyl phthalate, organic bentonite and polyamide wax at a mass ratio of 1:1 3 parts of thixotropic agent and 12 parts of deionized water.

[0039] The preparation method of melamine-coated ammonium polyphosphate is as follows:

[0040] Add melamine resin to deionized water, heat up to 40°C and stir to dissolve, add phosphoric acid wit...

Embodiment 3

[0046] A water-based polyurethane flame-retardant adhesive prepared from raw materials with the following weight fractions:

[0047] 35 parts of isophorone diisocyanate, 16 parts of toluene-2,4-diisocyanate, 5 parts of polybutylene adipate, 25 parts of 2,2-bis(hydroxymethyl)propionic acid, polytetrahydrofuran ether two 12 parts of alcohol, 1 part of trimethylolpropane, 0.1 part of dibutyltin dilaurate, 0.2 part of stannous octoate, 5 parts of diethylene glycol, 2 parts of bismaleimide, 20 parts of acetone, triethanolamine 1 part, 8 parts of sodium-based montmorillonite, 18 parts of melamine-coated ammonium polyphosphate, 2 parts of plasticizer butyl benzyl phthalate, organic bentonite and polyamide wax in a mass ratio of 1:1 2 parts of thixotropic agent and 14 parts of deionized water.

[0048] The preparation method of melamine-coated ammonium polyphosphate is as follows:

[0049] Add the melamine resin to deionized water, heat up to 40°C and stir to dissolve, add phosphoric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com