Flame-retardant wall brick

A technology of wall bricks and bentonite, applied in building materials, building components, buildings, etc., can solve problems such as difficulty in rescue, high probability of occurrence, and difficulty in escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

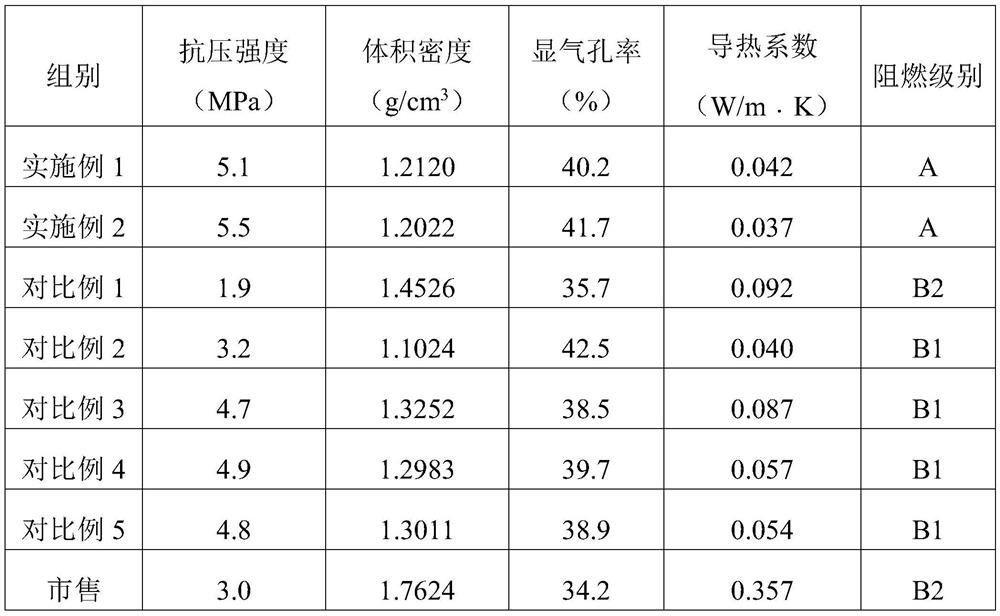

Examples

Embodiment 1

[0032] Flame-retardant wall tiles are composed of the following raw materials in parts by weight: 150 parts of white cement, 70 parts of expanded polystyrene, 20 parts of porous flame-retardant hollow microspheres, 75 parts of silica airgel, 15 parts of bentonite, and 8 parts of feldspar , 2 parts of polyacrylamide, 7 parts of rock wool fiber, 3.5 parts of calcium carbonate.

[0033] The porous flame-retardant hollow microspheres are prepared by the following method:

[0034] S1. Preparation of oil phase: 100g Al(O-s-C 4 h 9 )3 Add 2g of aluminate coupling agent DL-411-A into 200mL of chloroform, and mix evenly with magnetic stirring at a speed of 500r / min to obtain an oil phase;

[0035] S2. Preparation of the water phase: Add 2g of the porogen polyethylene glycol octylphenyl ether and 1g of the surfactant sodium dodecylsulfonate into 500mL of water, and mix evenly with magnetic stirring at a speed of 500r / min to obtain water box;

[0036] S3. Preparation of porous flame-...

Embodiment 2

[0044] Flame-retardant wall tiles are composed of the following raw materials in parts by weight: 150 parts of white cement, 70 parts of expanded polystyrene, 20 parts of porous flame-retardant hollow microspheres, 75 parts of silica airgel, 15 parts of bentonite, and 8 parts of feldspar , 2 parts of polyacrylamide, 7 parts of rock wool fiber, 3.5 parts of calcium carbonate.

[0045] The porous flame-retardant hollow microspheres are prepared by the following method:

[0046] S1. Preparation of oil phase: 100g Al(O-i-C 3 h 7 ) 3 Add 5g of aluminate coupling agent DL-411-D into 200mL of ethyl acetate, and mix evenly with magnetic stirring at a speed of 700r / min to obtain an oil phase;

[0047] S2. Preparation of the water phase: Add 5g of the porogen polyoxyethylene sorbitan fatty acid ester and 1g of the surfactant sodium octadecylbenzenesulfonate into 500mL of water, and mix evenly under magnetic stirring at a speed of 700r / min , to obtain the aqueous phase;

[0048] S3....

Embodiment 3

[0112] Flame-retardant wall tiles, consisting of the following raw materials in parts by weight: 150 parts of white cement, 70 parts of expanded polystyrene, 20 parts of porous flame-retardant hollow microspheres, 75 parts of silica airgel, 15 parts of modified bentonite, feldspar 8 parts, polyacrylamide 2 parts, rock wool fiber 7 parts, calcium carbonate 3.5 parts.

[0113] The modified bentonite is prepared by the following method: 15 parts by weight of bentonite and 5 parts by weight of melamine polyphosphate are added to 100 parts by weight of water, mixed evenly, and ultrasonically treated at 85°C for 35 minutes; Ethylene glycol formate was mixed evenly, reacted at 160°C for 20 minutes, cooled to room temperature, filtered and dried to obtain modified bentonite.

[0114] The porous flame-retardant hollow microspheres are prepared by the following method:

[0115] S1. Preparation of oil phase: 100g Al(O-i-C 3 h 7 ) 3 Add 5g of aluminate coupling agent DL-411-D into 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com