A laminated mold and process method for microcellular foaming injection molding

A technology of microcellular foaming and laminated molds, which is applied in the field of appearance injection molding parts to achieve the effects of avoiding the decline of mechanical properties, high production efficiency, and preventing dynamic foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

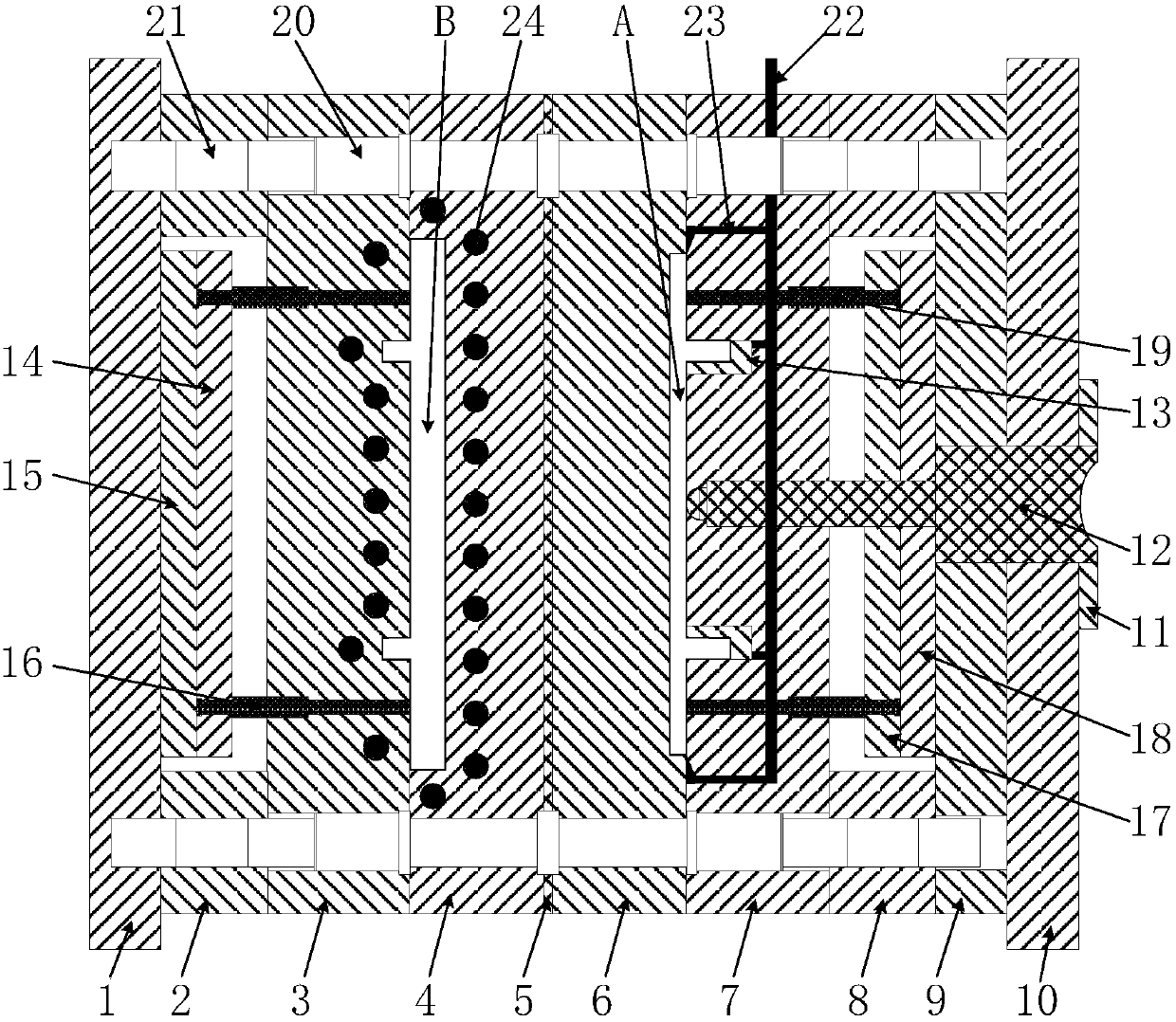

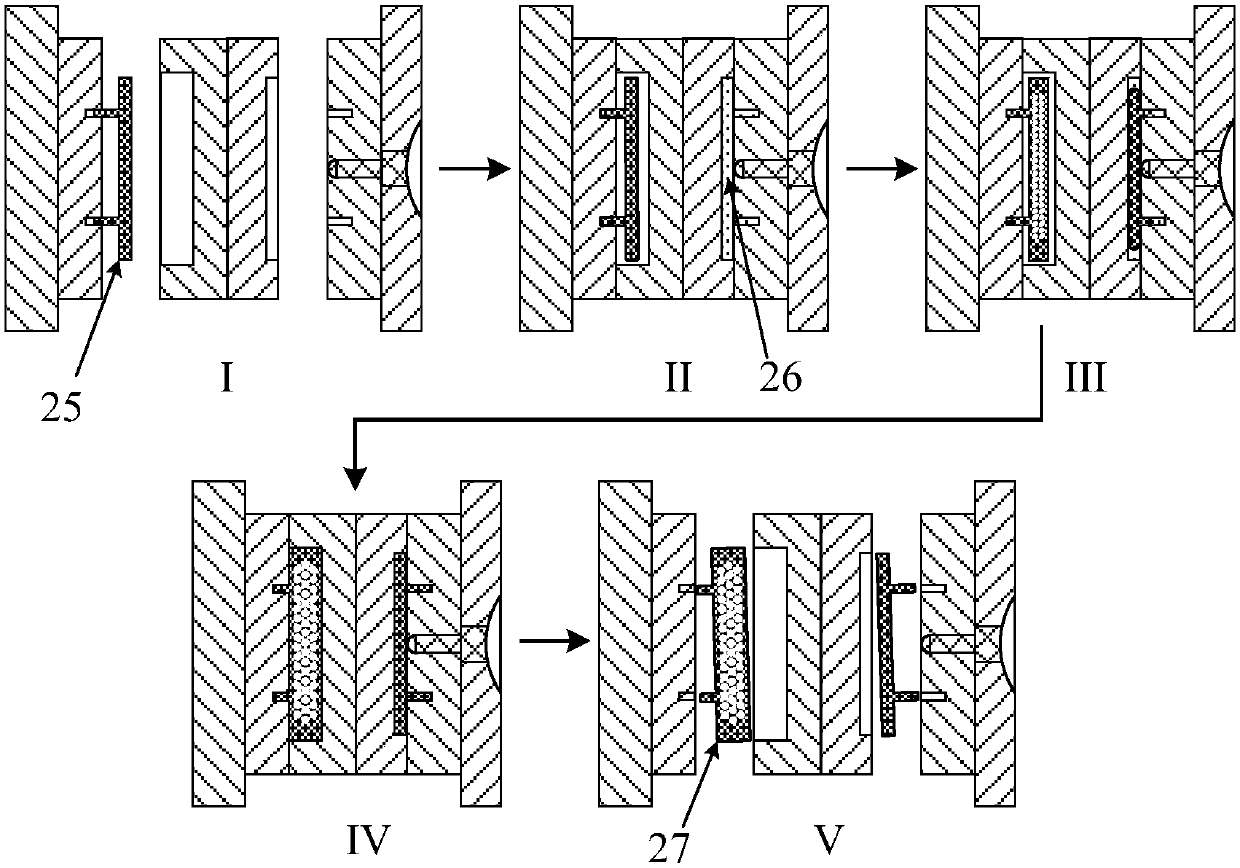

[0041] The invention provides a laminated mold structure and process method for microcellular foaming injection molding. Through the two cavities of the laminated mold, the preform containing the foaming agent and the final product containing the dense cell structure are molded respectively. Among them, the high-pressure injection process is used in the preform preparation process to prevent the preform from foaming; the preform cannot contact the mold wall surface of the outer surface of the molded product in the final product molding cavity. Wherein the volume of the preform molding cavity A can be controlled in the range of 40-99% of the volume of the final product molding cavity B, the specific structure is as follows figure 1 As shown, the laminated mold used for microcellular foaming process includes: movable mold seat plate 1, movable mold side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com