Microcellular foaming injection molding technology capable of realizing high foaming ratio and preventing surface from having foam marks

A technology of microcellular foaming and expansion ratio, which is applied in the field of injection molding parts to achieve the effects of avoiding the decline of mechanical properties, high efficiency, excellent expansion ratio and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

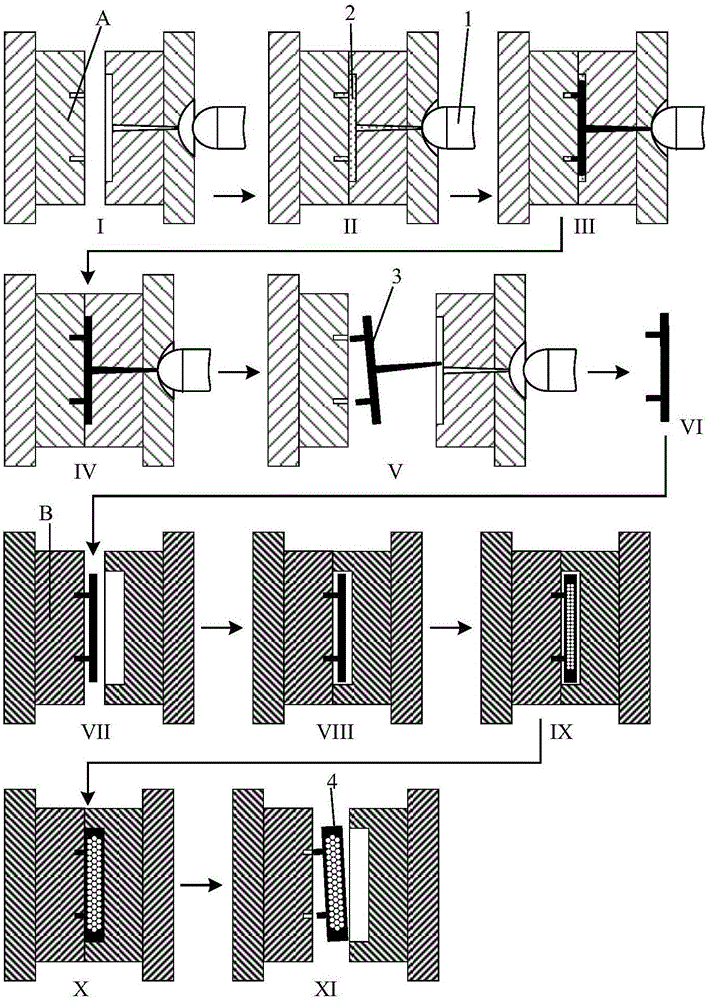

[0030] Such as figure 1 As shown, the microcellular foaming injection molding process disclosed in the present invention includes: preparation before injection, preform forming, preform transfer, heating and foaming, and obtaining the final product after cooling. Wherein, the preform and the final product are formed in two mold cavities with different volumes. In this embodiment, two sets of molds are used to form the preform and the final product respectively, but the specific process is as follows, including the following specific steps:

[0031] Step (1), preparation before injection, includes mold opening I and mold closing pressurization II. The microcellular foaming injection molding machine mixes the foaming agent evenly into the polymer melt, and maintains a high-pressure environment to prevent premature foaming. After the preform cavity is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com