A Prediction Method of Surface Heat Transfer Coefficient in Strip Hot Rolling Process

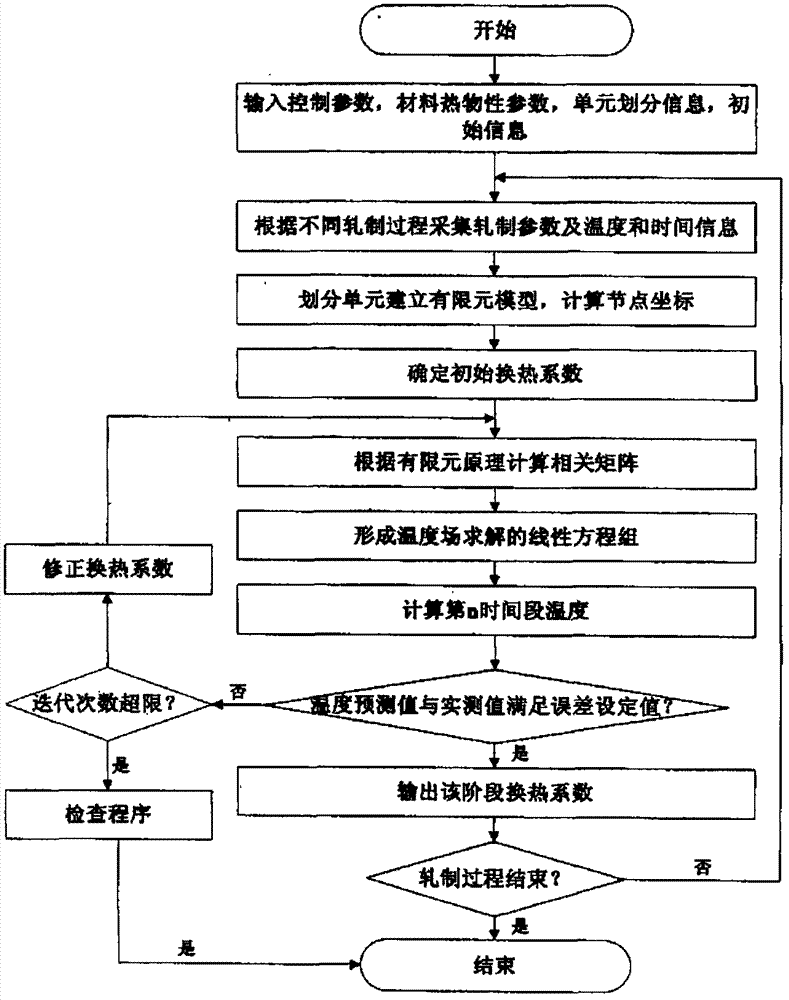

A technology of surface heat transfer coefficient and hot rolling process, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of weak professionalism and low precision, and achieve strong applicability and optimized rolling process. , the effect of detailed and accurate information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

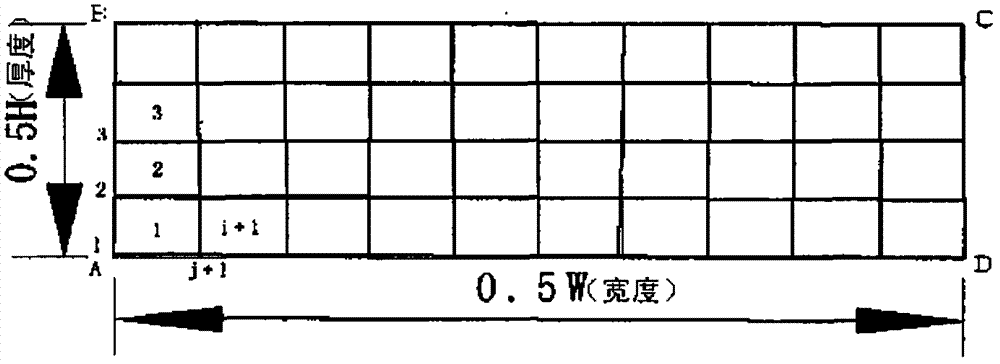

[0135] Example 1: Hot continuous rolling process in a steel mill. There are 4 stands in the rough rolling process, and the second stand is a reversible stand; there are 7 stands in the finish rolling process. The reversible stand is rolled 5 times, and the rest of the stands are rolled once.

[0136] Example: See Table 1 for calculation conditions.

[0137] Table 1 Calculation conditions

[0138]

[0139]

example 2

[0140] Example 2: In the entire hot continuous rolling process, there are 15 rolling passes in total, and the exit thickness and rolling pressure of each rolling pass are shown in Table 2.

[0141] Table 2 Pass outlet thickness

[0142]

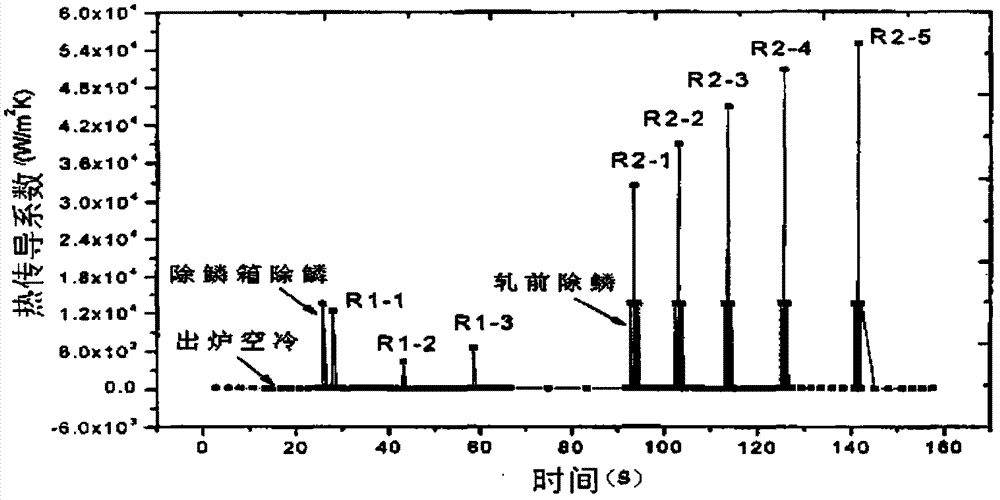

[0143] Using the calculation conditions in Table 1 and the exit thickness and rolling pressure in Table 2, the change rule of the heat transfer coefficient of the strip surface during the hot rolling process in a certain steel plant is predicted. Calculated as image 3 and Figure 4 ,in image 3 is the heat transfer coefficient change in the process from the furnace to the exit of the rough rolling; Figure 4 It is the change of heat transfer coefficient in the process from the exit of rough rolling to the exit of finish rolling. It can be seen that the heat transfer coefficient of the air cooling process is basically similar, about 80 (W / m 2. K), the heat transfer coefficient of the descaling process is about 1.25×10 4 (W / m 2. K), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com