Method for producing metal titanium roll with thickness not more than 0.3mm through twenty-roller cold rolling unit

A 20-roller, metal titanium technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problem of not being able to roll thin titanium strips and coils, and achieve the effect of optimizing the rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

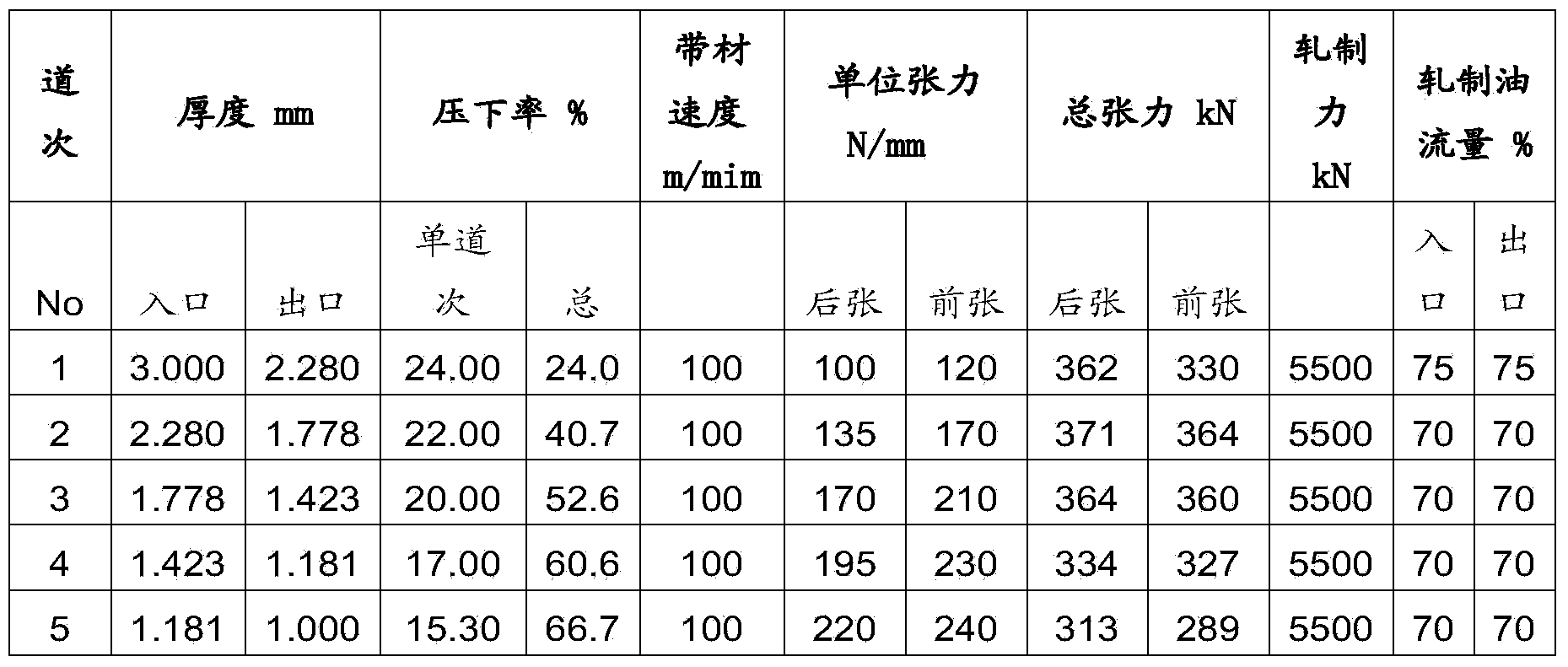

[0036] In order to clarify the rolling process of titanium coils, two specific processes are listed below.

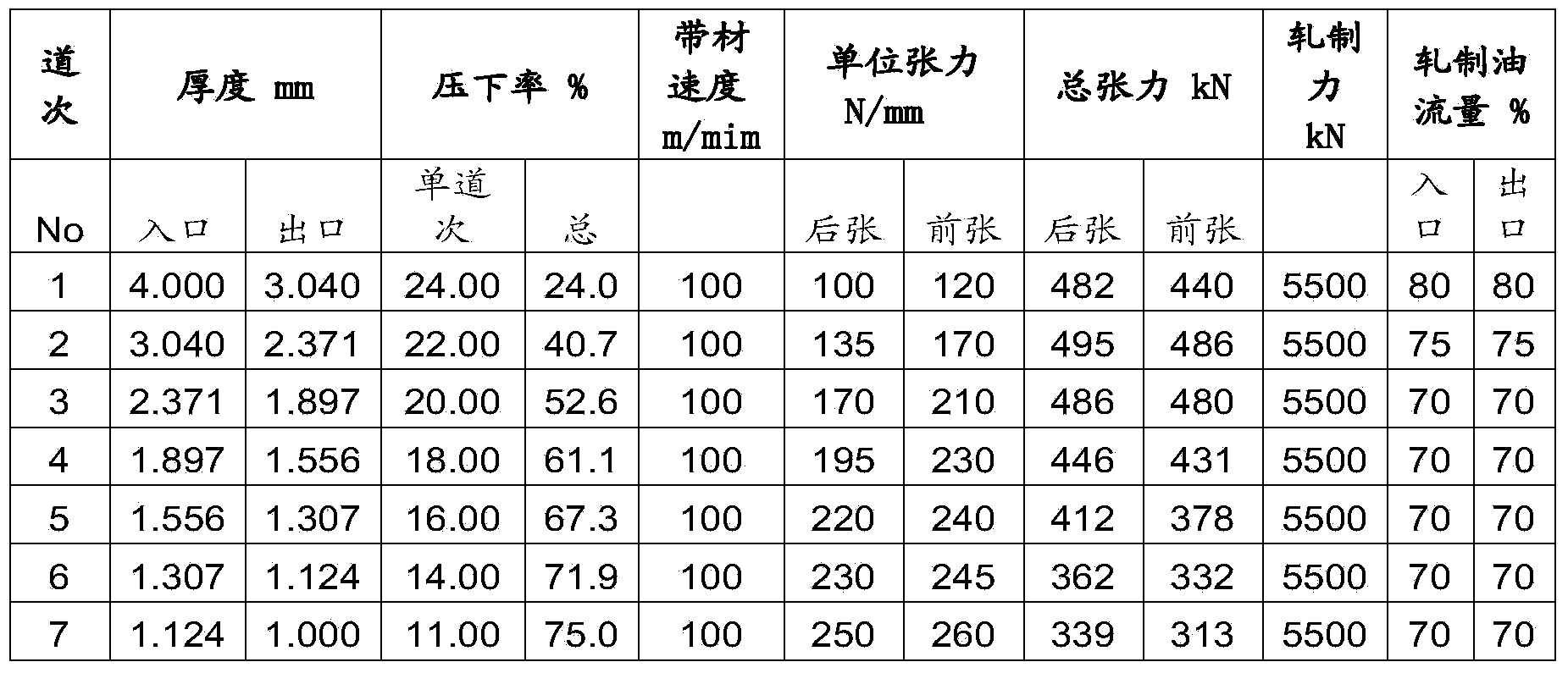

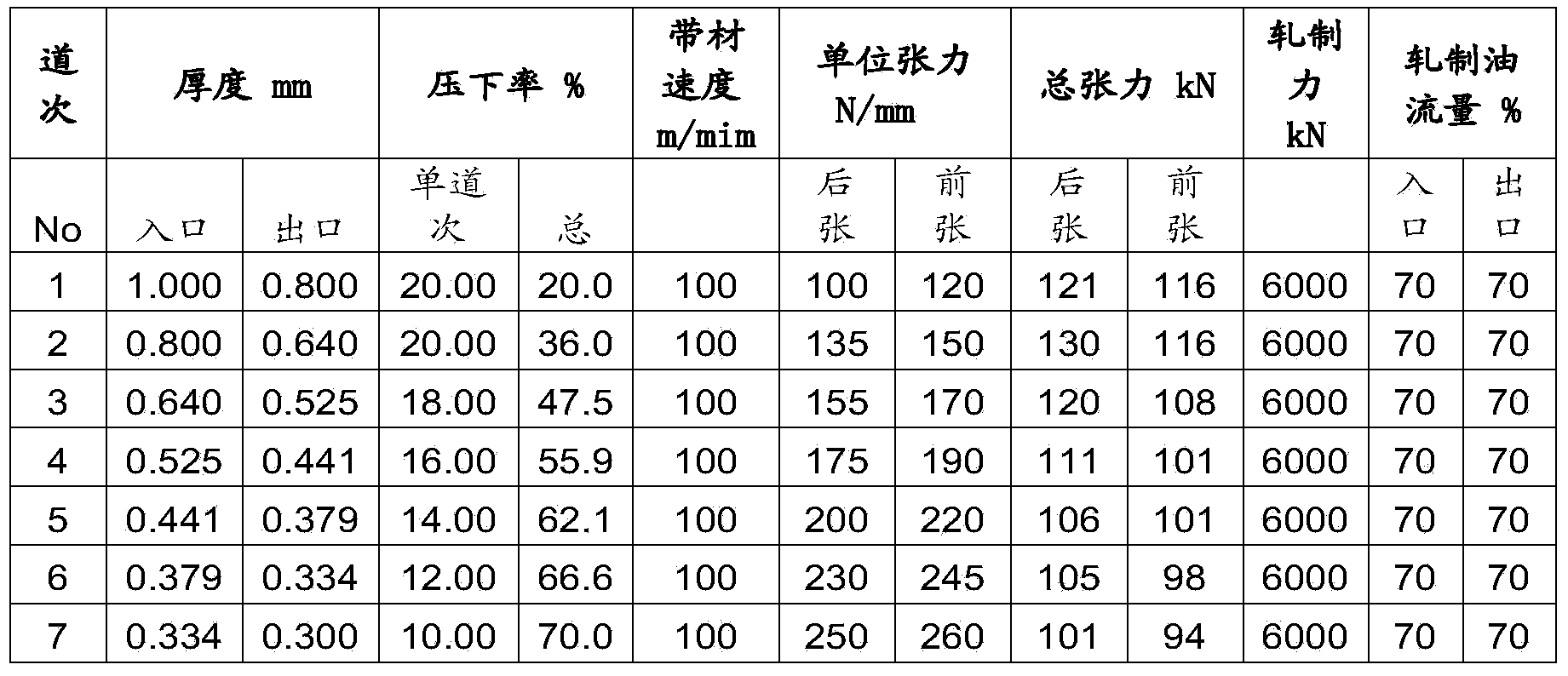

[0037] 1. The rolling table of 4.0mm-1.0mm-0.3mm thick titanium coil is shown in Table 1 and 2:

[0038] Rolling table of 4mm thick titanium coils rolled on a twenty-high reversing cold rolling mill

[0039] Table 1: Rolling schedule of 4mm thick titanium coils rolled on a 20-high reversing cold rolling mill (first rolling pass)

[0040]

[0041] It can be known from the above table that the total reduction rate increases layer by layer, and the growth rates are 69.58%, 29.24%, 16.15%, 10.14%, 6.83%, and 4.31%, respectively. The unit front tension of the seven passes is 1.2, 1.26, 1.24, 1.18, 1.09, 1.06, 1.04 of the unit back tension. The total back tension of the seven passes is 1.09, 1.01, 1.01, 1.03, 1.08, 1.09, 1.08 of the total front tension.

[0042] The rolling oil flow used is 70-80% of the total rolling oil flow of the twenty-high cold rolling mill, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com