A large-thickness 1000mpa grade non-quenched and tempered high-toughness structural steel and its preparation method

A structural steel, non-quenched and tempered technology, applied in the direction of metal rolling, etc., can solve the problems of being unable to meet ultra-high strength, large thickness, high toughness and non-quenched and tempered at the same time, and achieve the effect of reducing process costs and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

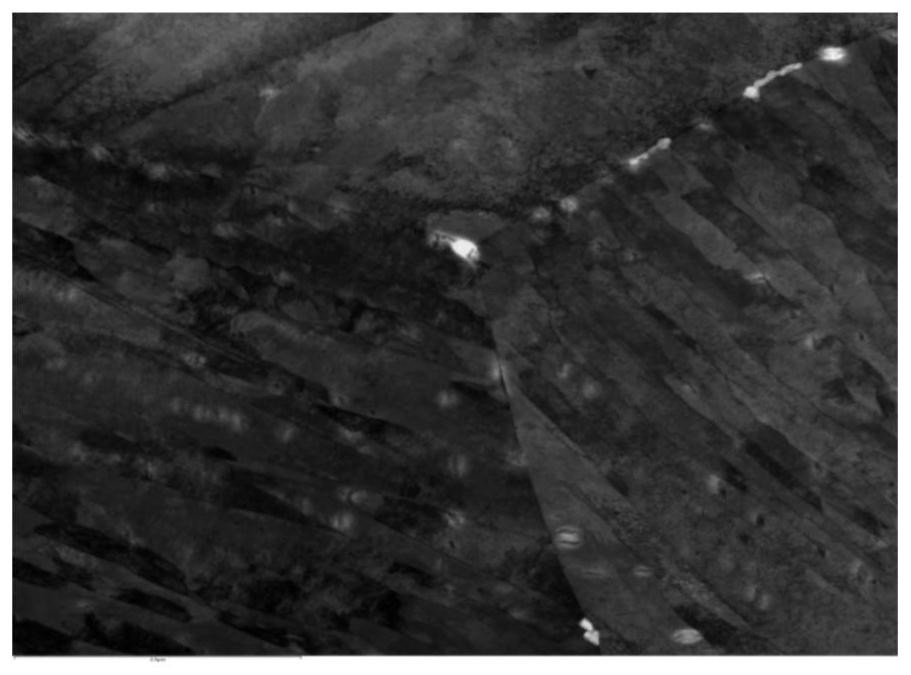

[0090] A preparation method of large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel, the method comprising:

[0091] obtaining the cast slab of the large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel;

[0092] heating, rolling, air-cooling and quenching the cast slab to obtain the large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel;

[0093] The heating temperature of the slab is 1160-1220°C;

[0094] In this application, if the heating temperature is too high, it is easy to cause coarse austenite grains, which is not conducive to the balance of strength and toughness, especially for extra-thick plates over 90 mm; too low heating temperature is not conducive to the dissolution of microalloying elements and rough rolling. Stages of austenite recrystallization.

[0095] The rolling adopts a two-stage controlled rolling process;

[0096] The quenching temperature of the q...

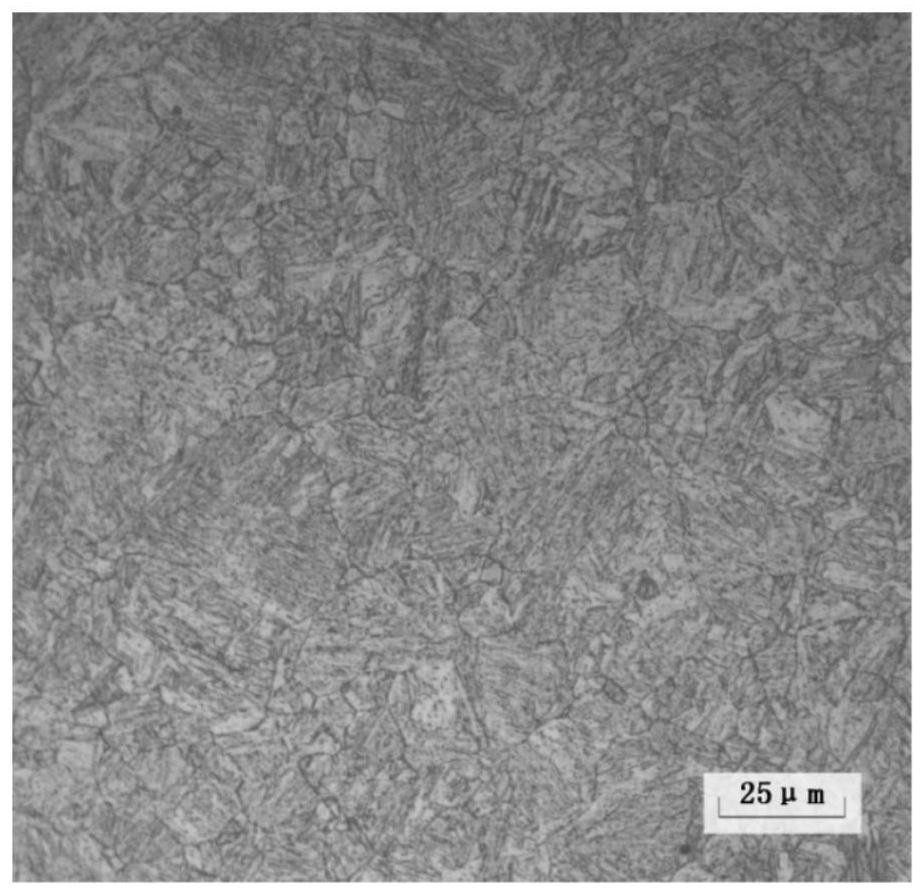

Embodiment 1

[0108] A large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel is prepared by the following method:

[0109] (1) Obtain the cast slab of the large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel, the slab size is 400*2000*3250mm, and in terms of mass fraction, the chemical composition of the cast slab is:

[0110] C: 0.11%, Si: 0.19%, Mn: 1.22%, P: 0.0047%, S: 0.001%, Ni: 0.92%, Cr: 0.44%, Mo: 0.39%, V: 0.056%, Cu: 0.28%, Nb: 0.027%, Ti: 0.013%, B: 0.0014%; the rest are Fe and inevitable impurities;

[0111] (2) Heating of the slab: the slab is heated to 1200°C and kept for 2.5h;

[0112] (3) Rolling: The rolling process is divided into two stages, the rolling in the recrystallization zone and the rolling in the non-recrystallization zone: the rolling temperature in the recrystallization zone is 1070 ° C, rolling to 135mm, and the cumulative pressure in the recrystallization zone is The reduction rate is 66%...

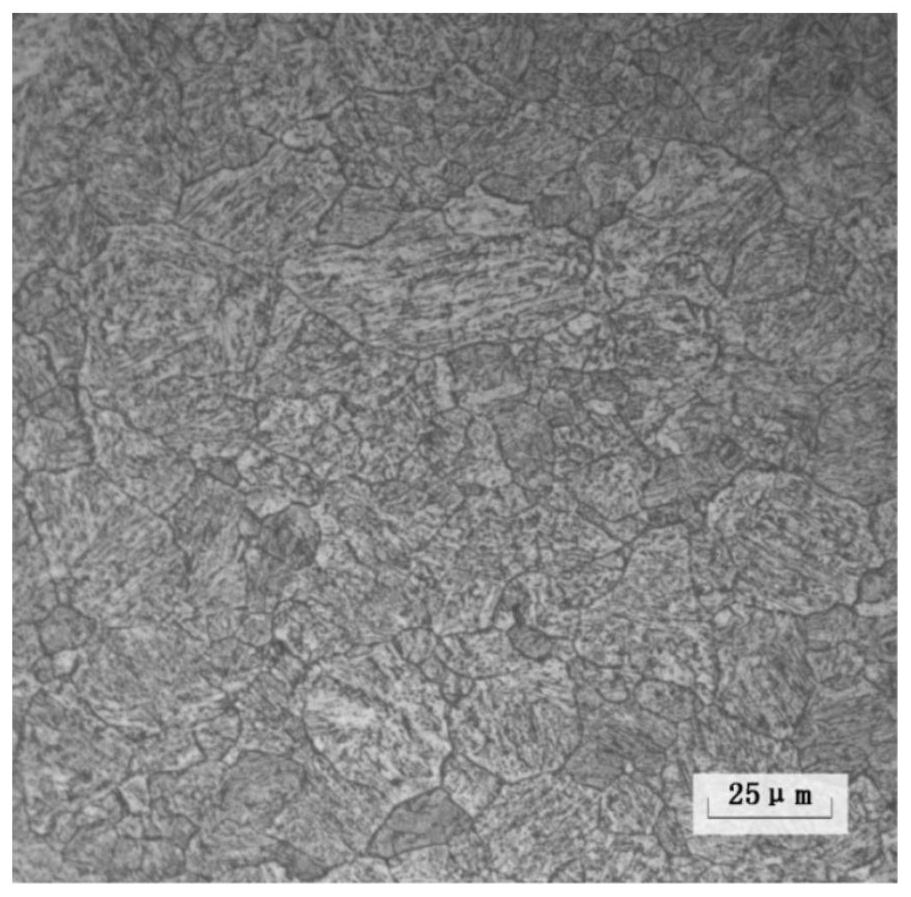

Embodiment 2

[0117] A large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel is prepared by the following method:

[0118] (1) Obtain the cast slab of the large-thickness 1000MPa grade non-quenched and tempered high-toughness structural steel, the slab size is 400*2000*3250mm, and in terms of mass fraction, the chemical composition of the cast slab is:

[0119] C: 0.13%, Si: 0.32%, Mn: 1.25%, P: 0.0049%, S: 0.00097%, Ni: 1.1%, Cr: 0.6%, Mo: 0.51%, V: 0.035%, Cu: 0.41%, Nb: 0.033%, Ti: 0.017%, B: 0.0014%; the rest are Fe and inevitable impurities;

[0120] (2) Casting billet heating: the casting billet is heated to 1206°C and kept for 130min;

[0121] (3) Rolling: The rolling process is divided into two stages, the rolling in the recrystallization zone and the rolling in the non-recrystallization zone: the rolling temperature in the recrystallization zone is 1177 ° C, rolling to 195mm, and the cumulative pressure in the recrystallization zone is The reduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com