A kind of methanol engine timing chain pin shaft vanadium infiltration agent and vanadium infiltration process

A methanol engine, vanadium infiltration technology, applied in metal material coating process, manufacturing tools, furnaces and other directions, can solve the problems of corrosion resistance, alcohol resistance, acid resistance, poor wear resistance, affecting the service life of the engine, and chain wear and elongation. , to enhance wear resistance and shear resistance, avoid chain wear and elongation or breakage, and improve surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A vanadium penetration agent for a timing chain pin shaft of a methanol engine, comprising ferrovanadium powder, alumina, aluminum powder and rare earth iodide, the mass percentages of each component are: ferrovanadium powder 40-60%, alumina 30-40% , 3 to 5% of aluminum powder, 3 to 5% of rare earth iodide, rare earth iodide is used to promote vanadium infiltration of pins. By using rare earth iodide as the penetration enhancer, it replaces the use of rare earth chloride as the penetration enhancer in the prior art, which helps to reduce the cracks of the infiltration layer on the surface of the pin shaft, achieves the thickness of the infiltration layer that meets the requirements of long mileage, and improves the sales volume. The wear resistance of the shaft increases the service life of the pin shaft.

Embodiment 2

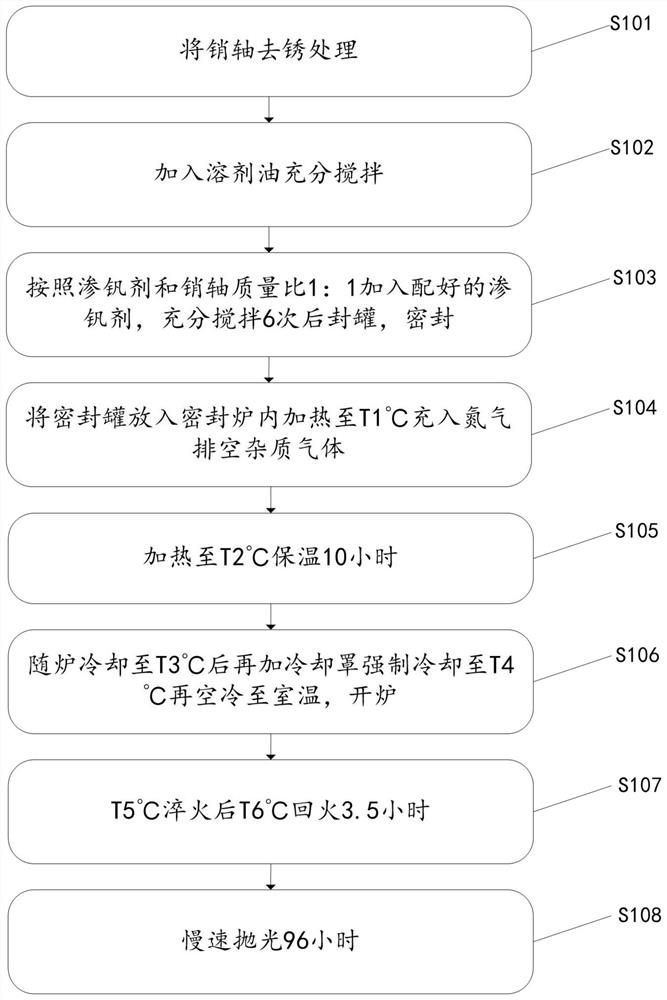

[0034] like figure 1 As shown, a kind of methanol engine timing chain pin shaft vanadium infiltration process is realized based on the vanadium infiltration agent in Example 1, and the process flow steps are as follows:

[0035] S101: Derusting the pin shaft;

[0036] S102: add solvent oil and stir fully (prevent vanadium penetration agent and pin shaft from sticking);

[0037] S103: add the prepared vanadium infiltrating agent according to the mass ratio of vanadium infiltrating agent and pin shaft 1:1, fully stir 6 times and then seal the tank and seal;

[0038] S104: Put the sealed tank into a sealed furnace and heat it to T1°C, fill it with nitrogen, and evacuate the impurity gas; the set value of T1 ranges from 180°C to 200°C, preferably 200°C.

[0039] S105: heating to T2°C for 10 hours; T2 set value range is 950-1000°C, preferably 970°C.

[0040] S106: cooling with the furnace to T3 °C, then adding a cooling cover to force cooling to T4 °C, then air-cooling to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com